PRE2023 3 Group11: Difference between revisions

No edit summary |

|||

| (40 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

= Thermal regulation of a fire-rescue robot = | |||

Tessa Groeneveld | == '''Group Members''' == | ||

{| class="wikitable" | |||

Abel Galambos | |+ | ||

!Name | |||

Elektra Katsikis - | !Student Number | ||

!Study | |||

|- | |||

|Storm Wilms | |||

|1839993 | |||

|BME | |||

|- | |||

|Tessa Groeneveld | |||

|1738941 | |||

|BPT | |||

|- | |||

|Abel Galambos | |||

|1846647 | |||

|BCS | |||

|- | |||

|Elektra Katsikis | |||

|1826654 | |||

|BCS | |||

|- | |||

|Roman Sinickis | |||

|1748939 | |||

|BAP | |||

|- | |||

|Tessa Cuijpers | |||

|1836927 | |||

|BME | |||

|} | |||

== '''Introduction & Problem Statement''' == | |||

A fire in a residential building is a common and critical emergency in any big urban area. Apart from the damage it does to the building, there are often people stuck inside whose lives depend on how quickly they are found and rescued by the firefighters. Sometimes, when the emergency services arrive at the scene, the entry to the building is already blocked by fire. The first question that a firefighting crew has, is how many people are inside and where they are. If the entry is blocked, or there are other complications, the search and rescue procedures can only be started after it is safe to enter the building. This delays the rescue and decreases the chances of people trapped inside surviving with every second. Often this leads to either firefighters entering the house even when it is still dangerous, or people not getting rescued in time. | |||

Technology is already being used by fire departments to optimise the process of putting out fires and evacuating survivors. For example, in some situations drones can be used to survey large open areas that are on fire. Technology is also used to allow the head firefighter to track where the fire fighters on site are at all times during fire. We want to provide a tool that can allow firefighting crews to locate survivors even before the fire has died down enough for units to enter the building, decreasing the total time it takes to rescue a person and decreasing the risks for the firefighters themselves. | |||

Our goal is to design a robot that can navigate hazardous high temperature environments, while equipped with sensors and communication technology allowing it to inform firefighters of where possible survivors may be located and how the situation is inside a room where it is still too dangerous for a human to enter. Over the course of this project we shifted from broader design and research to more specific topics to optimise, such as sensors or materials. We investigated multiple possible users and worked in collaboration with both to design a useful and innovative solution. To achieve this we developed a heat shield and gas cooling system that can be applied to a variety of different robots or integrated in new designs allowing robots to navigate more extreme environments. | |||

== '''Objectives''' == | == '''Objectives''' == | ||

| Line 28: | Line 52: | ||

Given the purpose of the robot as well as its objectives, this project will focus on the design. Additional prototypes could be developed but is not the focus for now. | Given the purpose of the robot as well as its objectives, this project will focus on the design. Additional prototypes could be developed but is not the focus for now. | ||

== '''USE Case''' == | |||

=== Users === | |||

== | |||

The users are mostly the firefighters using the robots to locate people in a burning building. They need to be able to quickly and easily understand where the robot has found people. The stakes will be high and time is very much of the essence. Another user group is the people who are in need of saving. If they are still conscious, they need to understand the robot is trying to help them, they should remain in the place where the robot found them as long as possible for the firefighter to easily find them. Other helpful tips like stay low to the ground to avoid breathing in smoke can be given to the people in need. | The users are mostly the firefighters using the robots to locate people in a burning building. They need to be able to quickly and easily understand where the robot has found people. The stakes will be high and time is very much of the essence. Another user group is the people who are in need of saving. If they are still conscious, they need to understand the robot is trying to help them, they should remain in the place where the robot found them as long as possible for the firefighter to easily find them. Other helpful tips like stay low to the ground to avoid breathing in smoke can be given to the people in need. | ||

The firefighters require, as mentioned, an easy to understand system. They cannot waste precious time on trying to figure out the cues the robot is giving because this will only interfere with the saving process instead of expedite it. They also need a product that is robust and will not break down in time of crisis, because that would again be wasting time. Another important factor is of course that the robot should not overlook people that can still be saved and should make clear that the firefighters should still keep their eyes peeled for potential victims it might have missed to avoid a mistake that would cost a life. | The firefighters require, as mentioned, an easy to understand system. They cannot waste precious time on trying to figure out the cues the robot is giving because this will only interfere with the saving process instead of expedite it. They also need a product that is robust and will not break down in time of crisis, because that would again be wasting time. Another important factor is of course that the robot should not overlook people that can still be saved and should make clear that the firefighters should still keep their eyes peeled for potential victims it might have missed to avoid a mistake that would cost a life. | ||

| Line 76: | Line 99: | ||

The people in need of saving need a robot that does not scare them. It should be immediately be clear the robot is their friend and if instructions are given to these people it should be very clear for them to understand even if they cannot see or hear which is quite likely in a burning building. | The people in need of saving need a robot that does not scare them. It should be immediately be clear the robot is their friend and if instructions are given to these people it should be very clear for them to understand even if they cannot see or hear which is quite likely in a burning building. | ||

== | == '''Process''' == | ||

Designing our robot was an involved process that involved a lot of research and contact with our users. Initial research was conducted by splitting the robot into various characteristics: transportation, sensors & image recognition, communication method, materials & fire resistance, and navigation & algorithm. This allowed us to get a good state of the art literature review (See Appendix ? TODO) while preparing to consult with our first users, the fire department. | |||

=== MoSCoW Requirements === | |||

Based on the literature review and the interviews with the firefighter and technical expert, as well as our own vision for the product, we have established a number of requirements that the robot we are working towards should meet. | |||

===== '''M'''ust Have: ===== | |||

* Ability to detect any human within 10 meters. | |||

*# Motivation: This is the central idea of the robot, thus it is also a core requirement. | |||

* Be directly controlled by a human operator. | |||

*# Motivation: this requirement was made crystal clear by the firefighters in the interview. | |||

* A visual feed from the robot to the operator. | |||

*# Motivation: From both interviews, our own intuition and from literature this requirement seems to go without saying, and our goal is not to break norms. | |||

* Maximum weight of 1.5kg, and maximum dimensions such that it can be carried by a firefighter on their belt. | |||

*# Motivation: The maximum weight is a clear constraint from the interview with the technical expert, and both interviews suggest that the desired use case is that the robot will be carried by the firefighters on their person. | |||

===== '''S'''hould Have: ===== | |||

* Semi-autonomous control. | |||

*# Motivation: A form of semi-autonomous control could ease the burden on the operator while still complying with the second must-have. | |||

* Ability to withstand short bursts of heat (namely 600 degrees for about 20 seconds). | |||

*# Motivation: From the interview with the firefighter we can see that these bursts of heat can happen, and we need the robot to be resilient so that it can freely go where victims might be. | |||

* Ability to monitor extra information, namely internal temperature, presence of obstacles. | |||

*# Motivation: This extra information could both be useful to the operator, and it could enhance the robot’s ability to stay operational. | |||

* Ability to display its own location on a map of the building. | |||

*# Motivation: From the interview with the firefighter we can see that this feature would be appreciated, and having it would also simplify the communication of the location of victims. | |||

===== '''Co'''uld Have: ===== | |||

* Ability to stay in the fire for extended periods of time. | |||

*# Motivation: While this could be useful, from the interview with the firefighters it seems that such situation can be avoided quite easily, thus it is nice o have but not necessary. | |||

* Recognize hotter areas and thus the core of the fire. | |||

*# Motivation: Depending on the sensors used this could be a simple task for our robot, but according to the interview with the firefighters, they can already handle such tasks. | |||

* Ability to navigate stairs. | |||

*# Motivation: Such a capacity could make the robot a lot more versatile, even if it can only go down or up, as seen in the interview with the technical expert. | |||

* Ability to convey information to the victims inside (i.e. a speaker or display). | |||

*# Motivation: As seen in our user analysis we want the robots presence to be perceived positively by the victims, this requirement could further aid the rescue by providing reassurance and proper instructions to the victims. | |||

=== ''' | ===== '''W'''on’t Have: ===== | ||

==== | * A fully autonomous operational mode: | ||

*# Motivation: Not only is this a difficult task to achieve, but it is also clear from the interview with the firefighters that this feature is not seen as a positive by the clients. | |||

* Ability to manipulate the environment (move objects/extinguish flames/etc). | |||

*# Motivation: Implementing such abilities would require a much larger and heavier robot then what previous requirements dictate. | |||

=== '''User interface''' === | |||

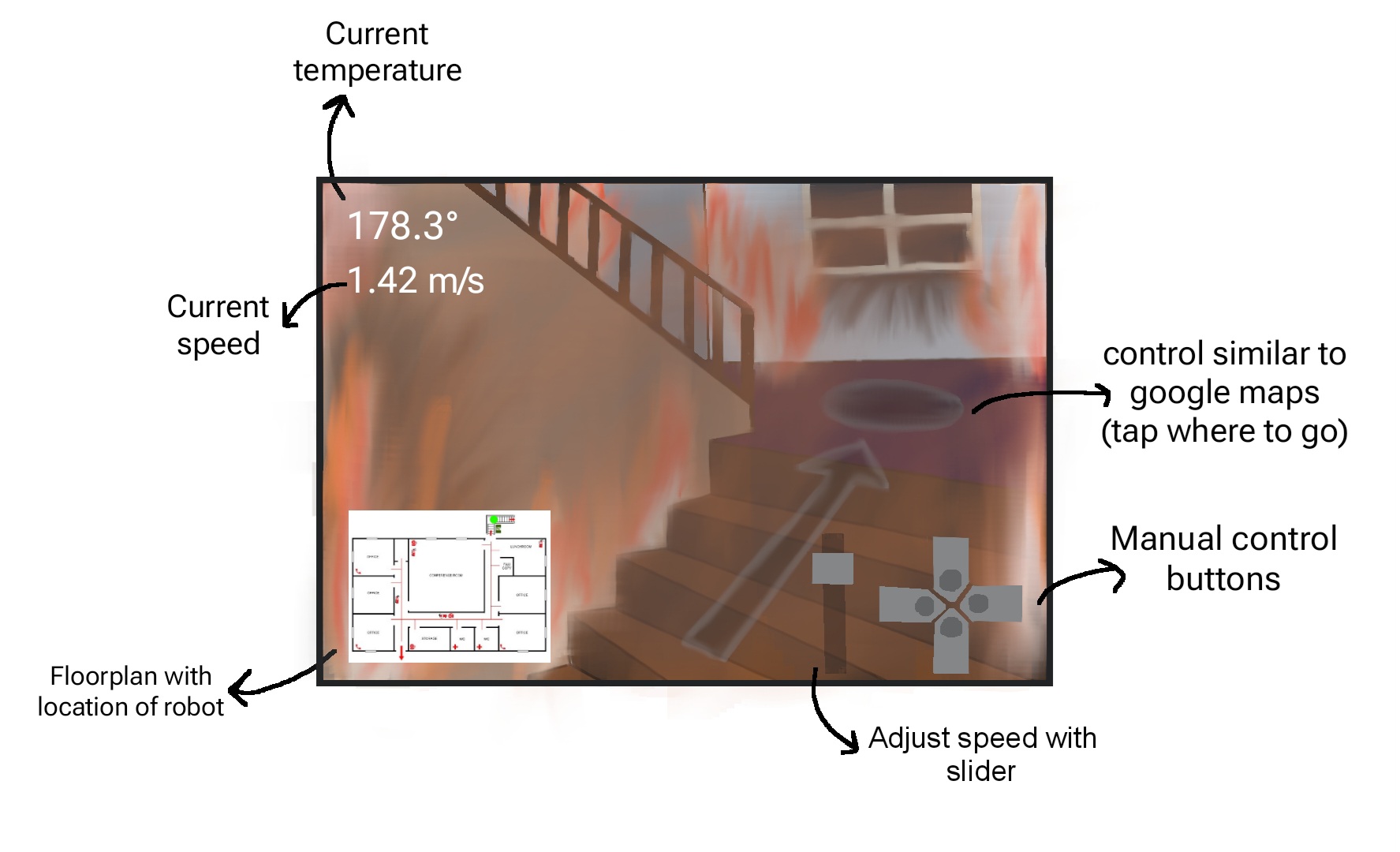

[[File:Interface users.jpg|thumb|527x527px|center]]From the interview, some more insight on how the robot’s user interface should work was obtained. Two things the user was quite adamant about are the easy control, without the use of some type of joystick controller, and the robot not being autonomous at all. | |||

Together with some own research, the elements of the interface were compiled into one design. Firstly, the user requested the control to be through finger movements on a tablet. This mostly signals that a simple way of control is desired, so the person controlling the robot needs no extra training. | |||

We opted for providing two ways of control, the first being reminiscent of Google maps. The user would swipe to or select the place they want to go and the robot would then go to this specified location. However, this might not always work perfectly if for example the robots ‘vision’ is not fully synced with that of the tablet. For this reason a more manual mode of control was added, being similar to that in video games. | |||

In order for the person controlling the robot to actually see where to go or use the Google maps type of control, a camera view is added as the main part of the interface design. However, smoke might obstruct vision and a general overview of where the robot is in the building is always handy. Therefore, a small map showing where the robot is in the building is added into the corner. The firefighters have access to a database of these evacuation maps for larger buildings, so these can be used for this purpose. | |||

A slider to adjust the speed was also added, incase the robot needs to speed up or slow down in specific situations. In order to know how much of an in- or decrease is needed, the current speed is shown in the top left corner. | |||

Above this, the current temperature detected by the robot is visible as well. The user can keep an eye on the temperature in order to avoid areas that will put the electronics of the robot in danger. For example, when above a certain temperature or when it starts increasing rapidly, the firefighter can change routes. However, there is no automatic stop when the temperatures get too high, which links back to the request for no autonomy. This means that the firefighters themselves can decide if the situation is urgent enough to potentially destroy the robot for and can continue going into the hot areas if deemed necessary. | |||

=== Material Analysis === | |||

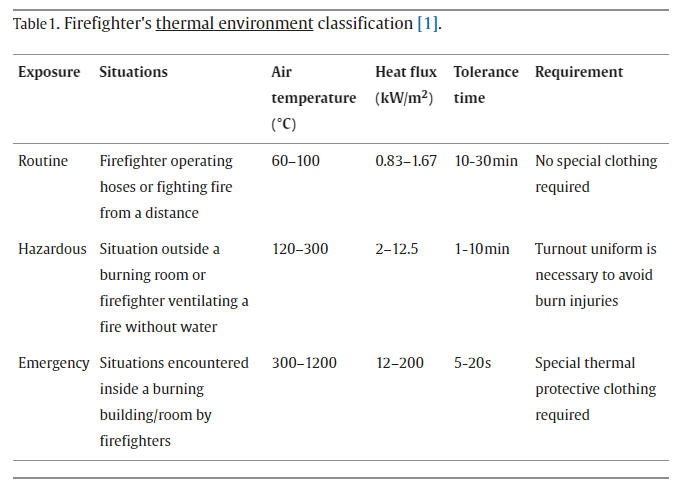

1) What are the protection requirements for a robot operating in a firefight? | 1) What are the protection requirements for a robot operating in a firefight? | ||

| Line 104: | Line 190: | ||

Another way is to have the rate of inner heating decreased to the point where the time required for heat accumulation to become dangerous would exceed the regular time of operation of the robot. While this seems to be ignoring the problem and requires more complex cover design, this simplifies the whole robot by removing active cooling system. It is obvious that any simplification of a system, especially a system operating in extreme conditions, leads to better reliability. (In other words, failure in cooling system = complete failure of the robot. Find a way to exclude cooling system = one less critical failure possible.) | Another way is to have the rate of inner heating decreased to the point where the time required for heat accumulation to become dangerous would exceed the regular time of operation of the robot. While this seems to be ignoring the problem and requires more complex cover design, this simplifies the whole robot by removing active cooling system. It is obvious that any simplification of a system, especially a system operating in extreme conditions, leads to better reliability. (In other words, failure in cooling system = complete failure of the robot. Find a way to exclude cooling system = one less critical failure possible.) | ||

==== | === Experiment === | ||

==== | ==== '''Experiment Plan''' ==== | ||

The experiment will be carried out in the Netherlands, Technical university of Eindhoven, Innovation Space in | |||

2024, with educational purposes. The goal of the experiment is to determine how much heat the perspective composite material can keep out of the insides of a robot. The materials that the composite will consist of are galvanized steel and ceramic fiber. These materials are sufficient in terms of the material research that had been done and are relatively available and cheap considering the user requirements from the interviews. | |||

During the experiment, the materials will form a shield resembling the heat cover on a robot. Galvanized steel will be positioned on the outside as a protective layer from physical damage and ceramic fiber will be on the inside, as the main heat insulation layer. Around these materials, several temperature sensors will be installed. The materials will then be exposed to a heat source. This can be achieved with a controllable heat source where the heat flux is known. The duration of each segment of the experiment is expected to be between 1-10 minutes. In this time range, the most extreme heat occurs in a burning building and should resemble the conditions close enough. The temperature sensors will monitor how the temperature changes over time in different parts of the composite, which can then be used to see how well the materials can withstand the heat. | |||

The experiment should be conducted with different thicknesses of insulating material, as different thicknesses can help to better understand the insulation capabilities of the composite. The robot heat shield should not be too thick because of size and weight limitations, so finding an optimal thickness that can be used for operation is a must. With the data it is expected to see how high the temperature can get inside a robot protected with such insulation, and how does the heat insulation elongate the time it takes for the robot to heat up. After the experiment it will be possible to make conclusions and a final recommendation will then be formed that says if the composite is a viable solution for robot insulation. | |||

In addition to the heating experiment, as a second part of the experiment the capabilities of a provisional compressed CO2 cooling system are going to be tested in a similar setup. With sensors around the cooling system the CO2 is going to be let out of a cartridge, allowing the gas to rapidly expand and thereby lower the temperature. Two attempts are going to be made with instant and graduate gas release. | |||

'' | ==== '''Setup of the experiment''' ==== | ||

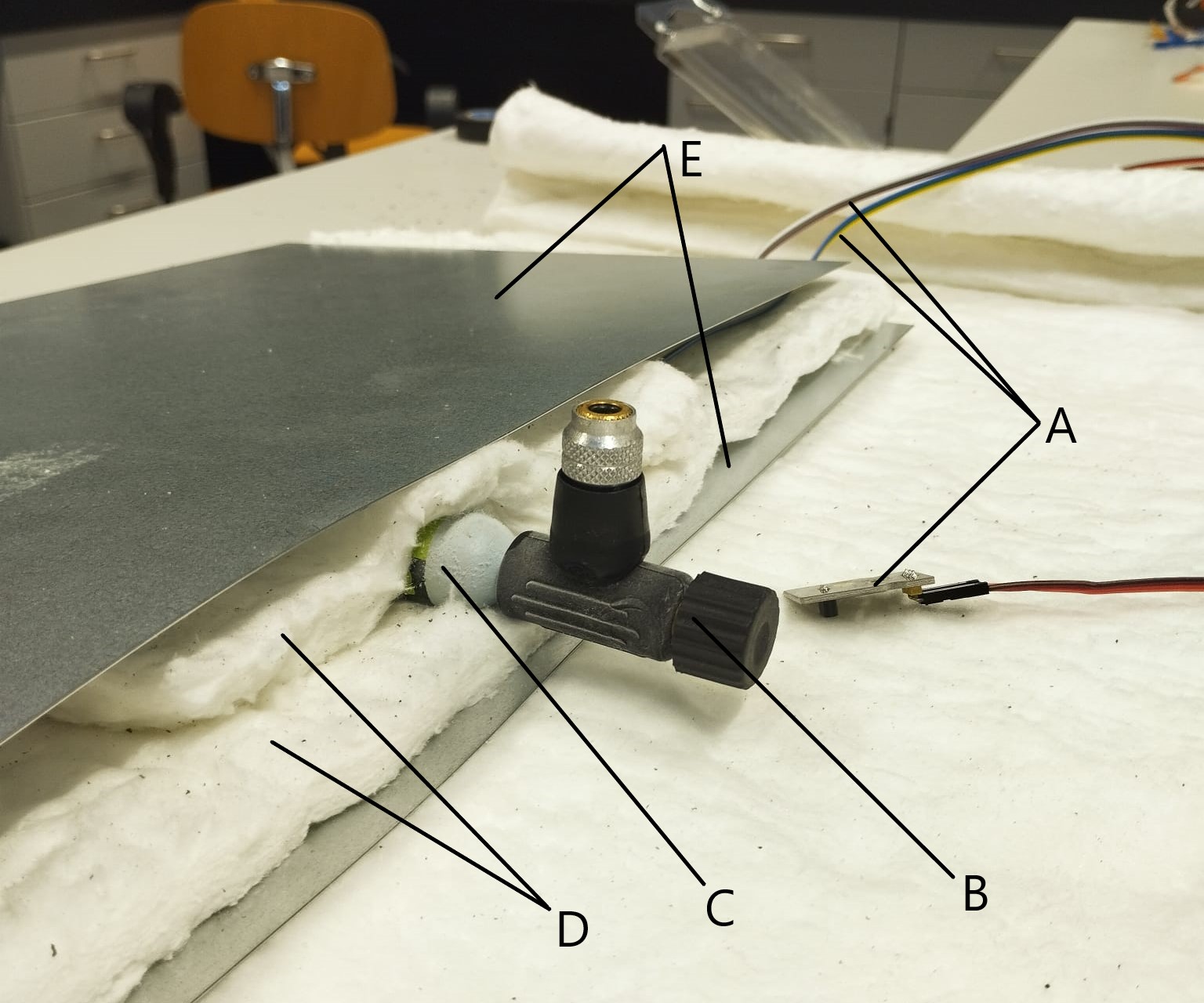

The set-up for the heating experiment can be seen on the Image (5.4.1). A galvanized steel sheet (C) 0.75 millimeters thick and a ceramic fiber sheet (D) 10 millimeters thick were combined into a composite heat shield. The size of the steel sheet was 250x500 millimeters and the same size sheets were cut out of ceramic fiber. The steel sheet and the ceramic fiber sheet are intentionally much larger than the area of the interest/the temperature sensor, so that later in the model the heat shield can be considered to have infinite area. The composite was positioned vertically, using the remaining ceramic fiber underneath the composite to protect the table surface. Then a smaller piece of ceramic fiber was attached on top of the big ceramic fiber sheet, to have two layered heat insulation. Three temperature sensors (A), connected to Arduino board, were placed around the setup: first one in front of the steel sheet, to imitate unprotected robot temperature, second one behind 1 layer of insulation and the last sensor behind 2 layers of insulation. Finally, a heat gun (B) from “PARKSIDE” which blows hot air at 350 or 550 degrees Celsius, depending on the setting. On the Image (5.4.1) the other heat gun is visible, but it was swapped for a more powerful one. When the sheets of ceramic fiber were cut, the operators used protective gloves, glasses and respirators, while performing the cutting in a highly ventilated location, as small particles of ceramic fiber are dangerous to inhale. During the experiment the operators used gloves, and care was taken when working with hot air and hot materials. | |||

[[File:Exp1 setup heat.jpg|center|thumb|540x540px|''Image 5.4.1: Photo of the heating experiment setup; A – Arduino temperature sensors; B – heat gun; C – galvanized steel sheet; D – ceramic fiber sheets.'' ]] | |||

==== | The set-up for the cooling experiment can be seen on the Image (5.4.2). A cooling system consisting of a cartridge with pressurized CO2 (C) and a manual gas valve (B) was covered with ceramic fiber sheets (D) to imitate the inside of a robot. Three temperature sensors (A) were positioned ass followed: one touching the cartridge to know its temperature, another one near the cartridge to know the temperature inside a robot, and the last one was held above the manual valve exit hole, to know the temperature of exiting CO2. Galvanized steel sheets (E) were placed around the ceramic fiber to cover the surface of the table and to put some pressure on top of the ceramic fiber sheets, to secure the position of temperature sensors. Again, the operators of the experiment used gloves, when touching the fiber glass and cold metal cartridges | ||

[[File:Exp2 setup cool.jpg|center|thumb|536x536px|''Image 5.4.2: Photo of the cooling experiment setup; A – Arduino temperature sensors; B – manual gas valve; C – cartridge with pressurized CO2; D – ceramic fiber sheets; E – galvanized steel sheets.'' ]] | |||

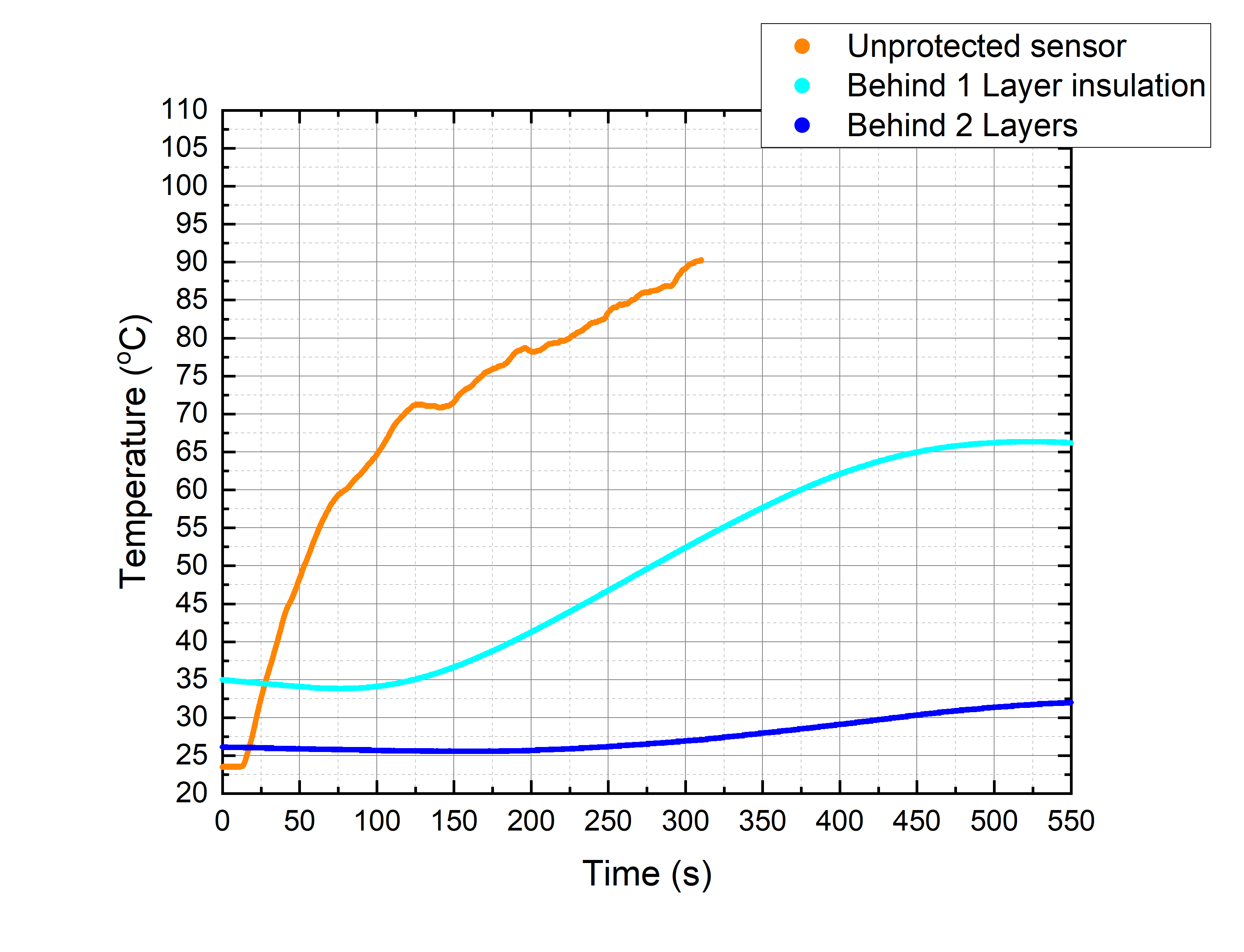

==== Experiment Results ==== | |||

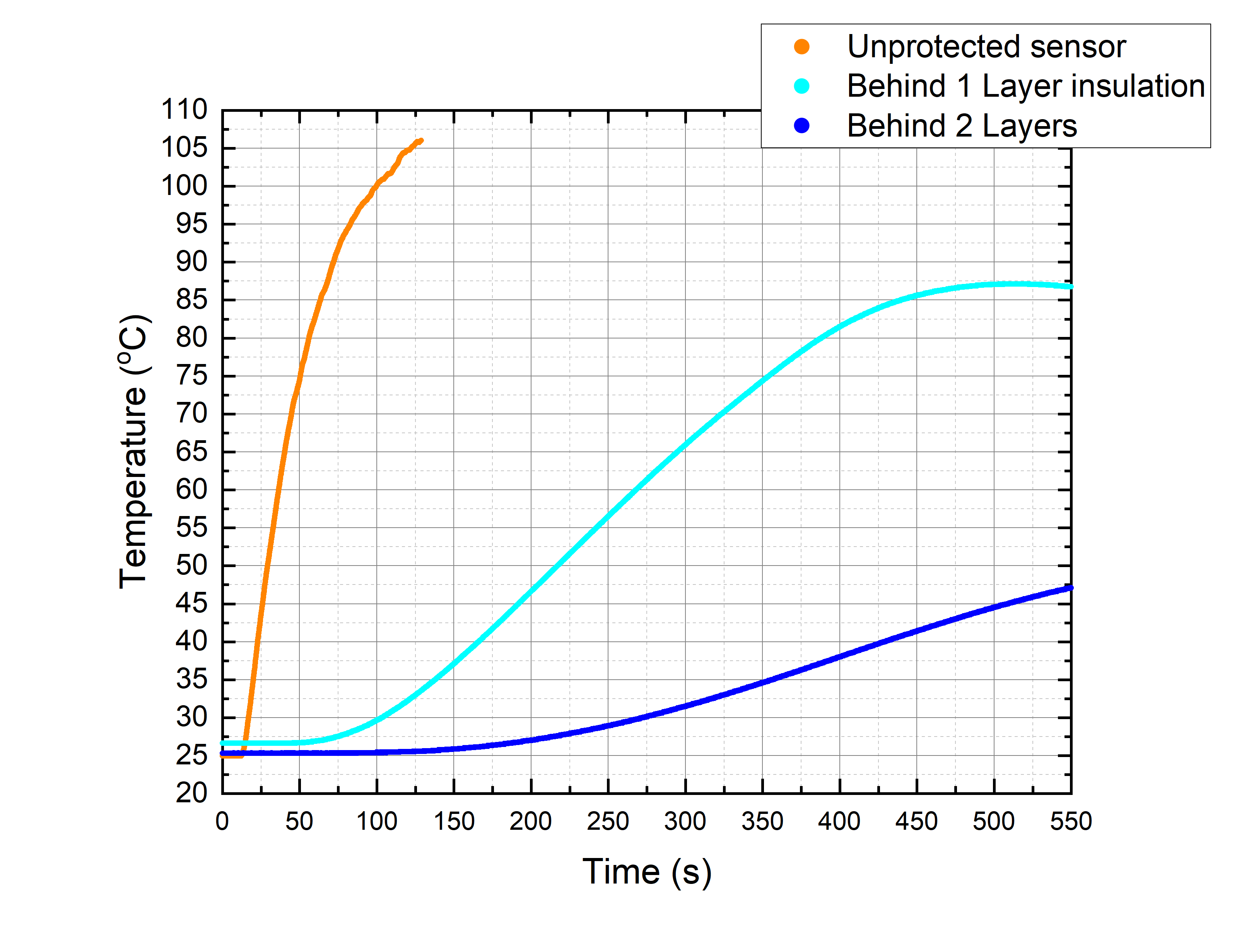

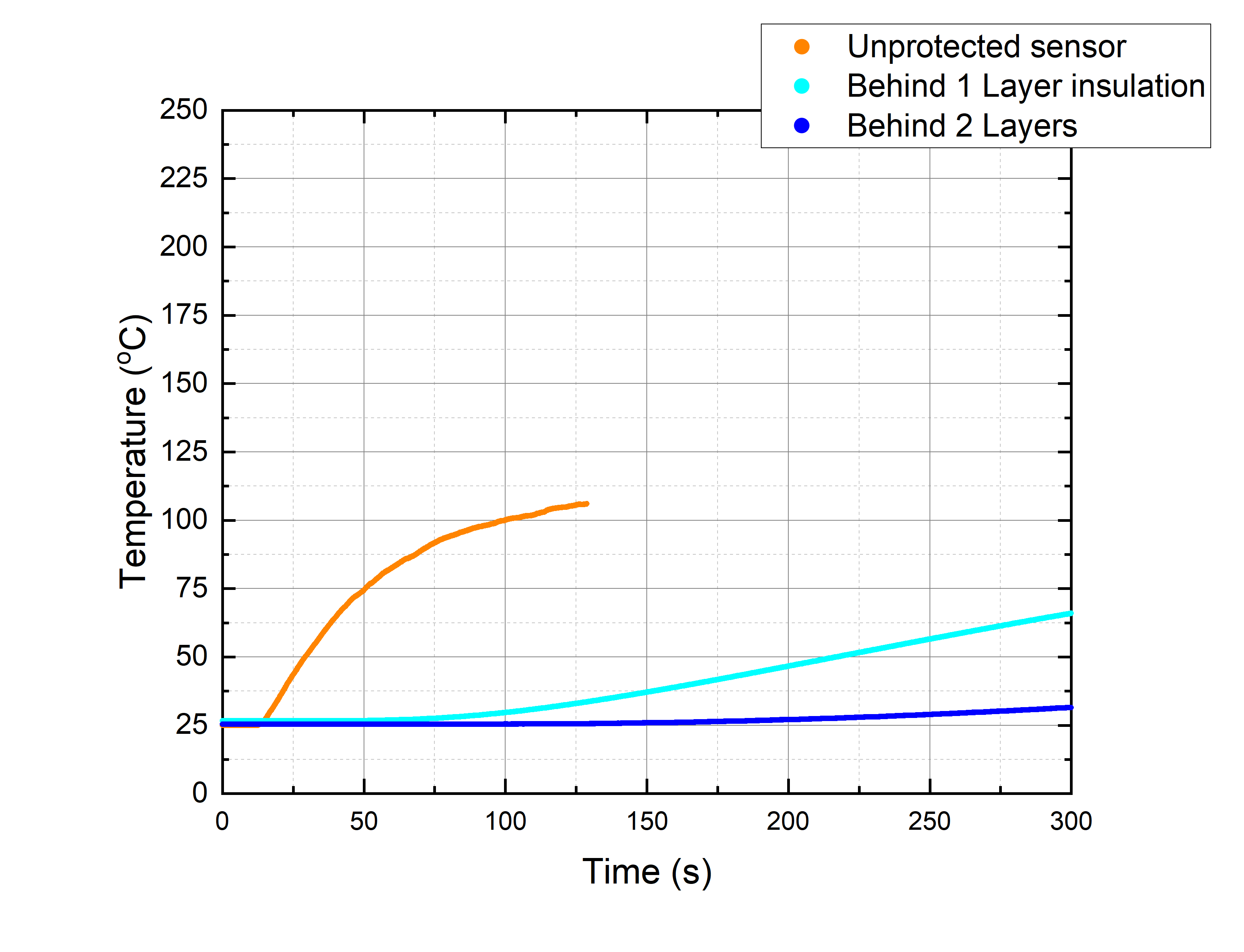

[[File:Exp2 medium heat graph FINAL.png|center|thumb|517x517px|''Image 5.4.3: Graph of the heating experiment with heat gun set to 350 <sup>o</sup>C temperature;'' ]] | |||

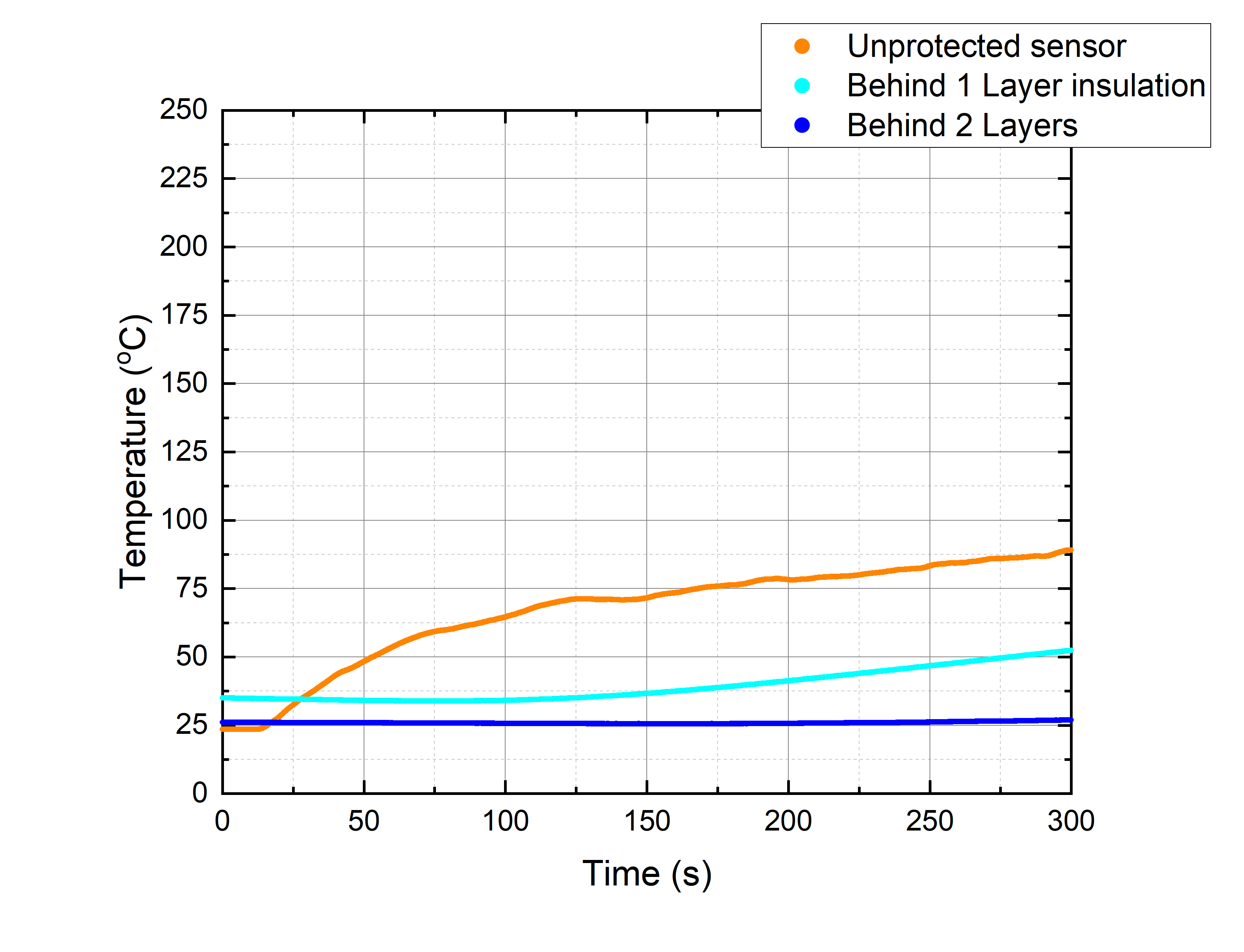

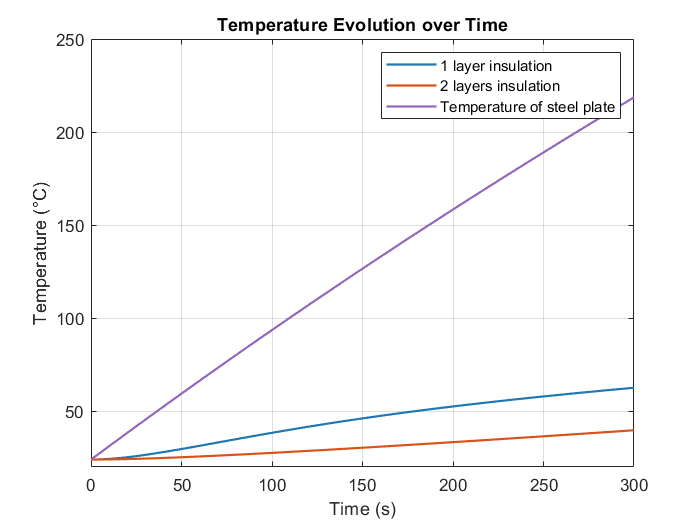

[[File:Exp3 max heat graph FINAL.png|center|thumb|519x519px|''Image 5.4.4: Graph of the heating experiment with heat gun set to 550 <sup>o</sup>C temperature;'' ]] | |||

By analyzing the linear parts of the slopes of image (5.4.3) and image (5.4.4) it was possible to compare the rate of temperature rise in unprotected scenario, with 1 or 2 layer insulation. The results of these calculations are visible in table (5.4.5) | |||

{| class="wikitable" | |||

| rowspan="2" |''Table 5.4.5'' | |||

| colspan="3" |Heat gun set at 350 <sup>o</sup>C | |||

| colspan="3" |Heat gun set at 550 <sup>o</sup>C | |||

|- | |||

|Unprotected | |||

|1 layer insulation | |||

|2 layer insulation | |||

|Unprotected | |||

|1 layer insulation | |||

|2 layer insulation | |||

|- | |||

|Temperature rise rate +-0.001 [<sup>o</sup>C/s] | |||

|0.326 | |||

|0.110 | |||

|0.010 | |||

|1.076 | |||

|0.197 | |||

|0.038 | |||

|- | |||

|Time it takes for the temperature to rise by 1 Celsius degree [s] | |||

|3.0 | |||

|9.1 | |||

|100.0 | |||

|0.9 | |||

|5.1 | |||

|26.3 | |||

|} | |||

From the table (5.4.5) it is seen that heat shield with 1 layer of insulation decreases the rate of temperature rise 3 times with incoming air at 350 ''<sup>o</sup>C'' and 5 times with the incoming air at 550 ''<sup>o</sup>C''. A heat shield with 2 layers of insulation decreases the rate of temperature rise 33 times and 29 times respectively. | |||

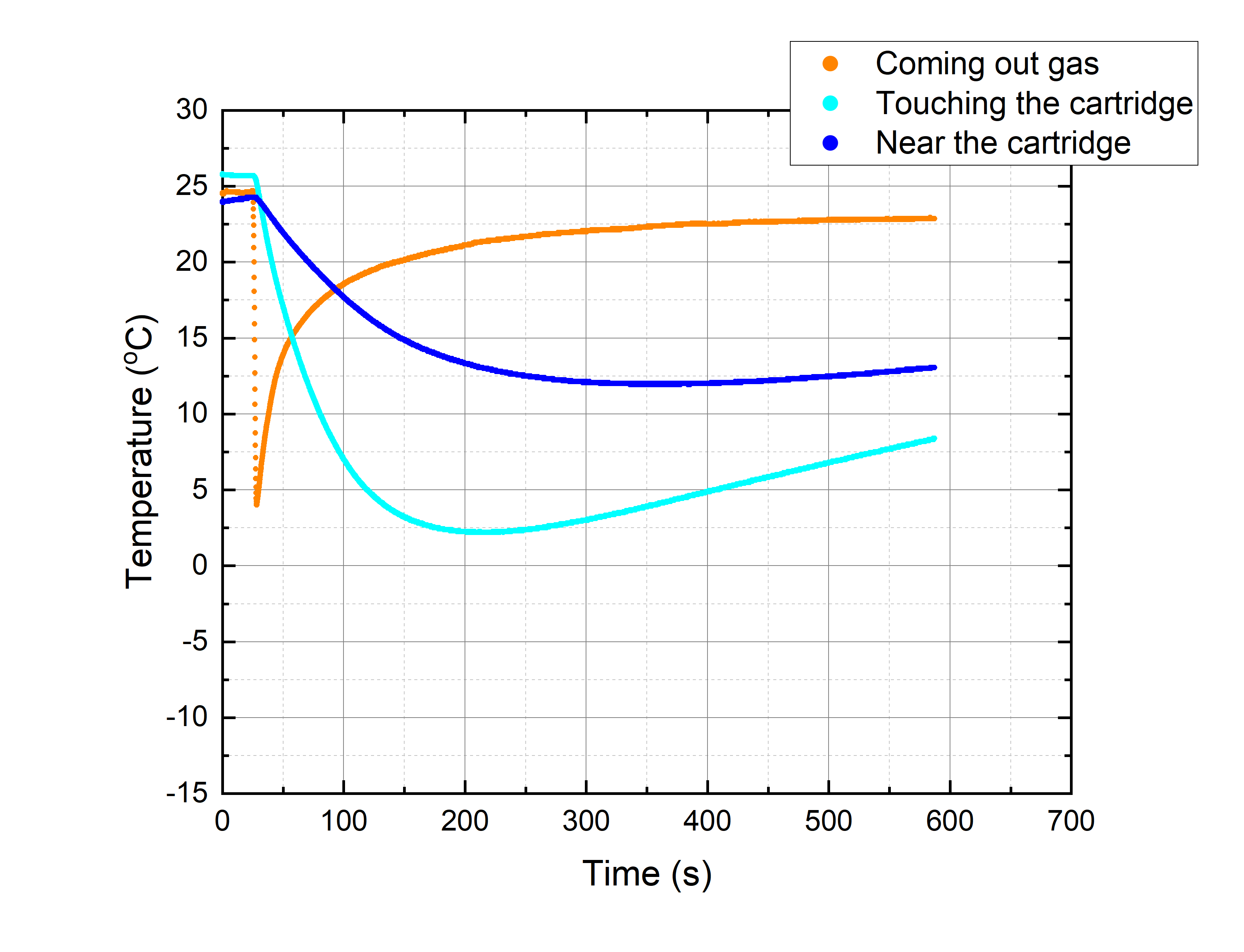

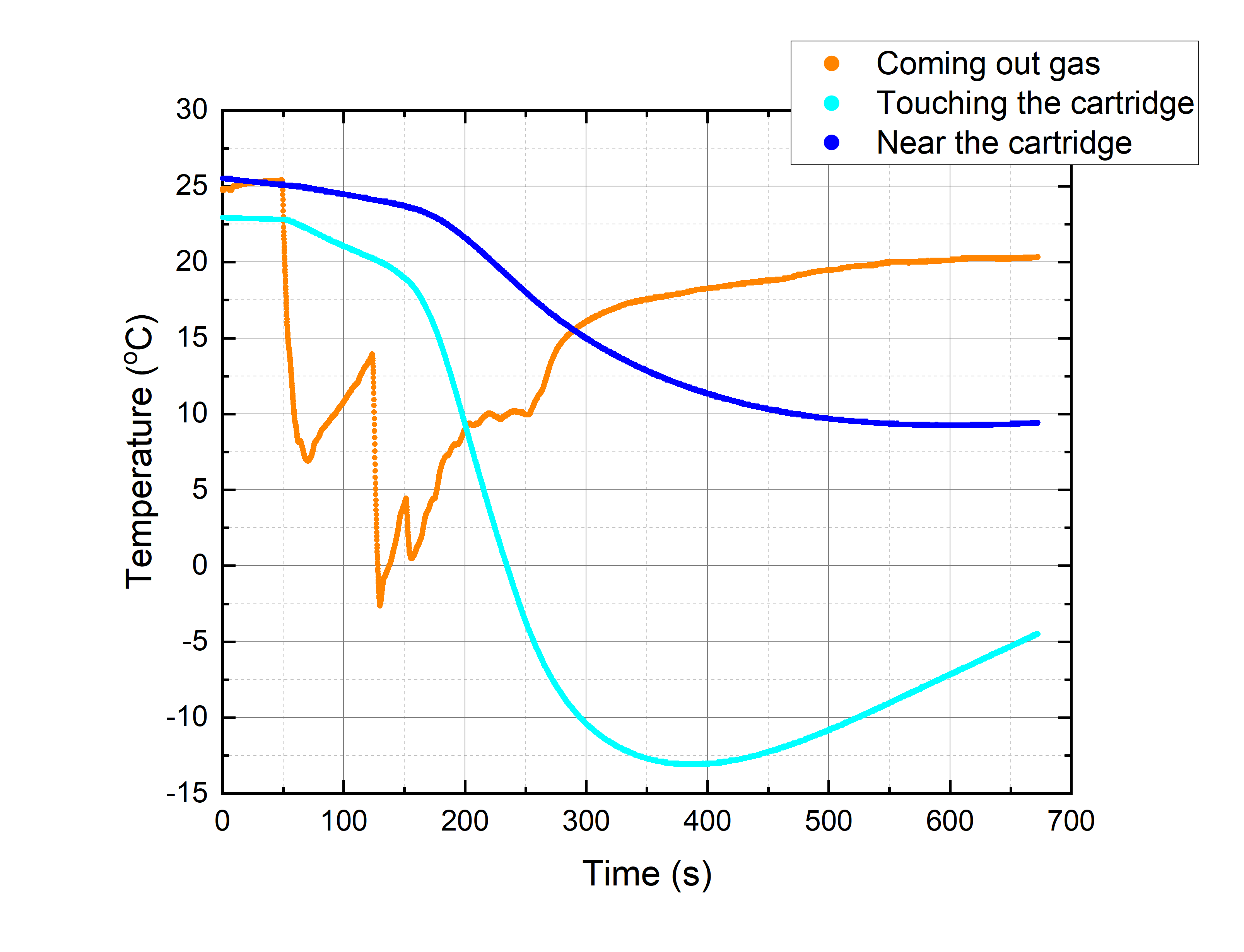

[[File:Exp6 instant cool graph FINAL.png|center|thumb|515x515px|''Image 5.4.6: Graph of the cooling experiment with the instant gas release'']] | |||

[[File:Exp5 gradient cool FINAL.png|center|thumb|500x500px|''Image 5.4.7: Graph of the cooling experiment with gradient gas release'']] | |||

By analyzing the graphs on the images (5.4.6) and (5.4.7) it is seen that graduate gas release allows for better cooling, but even theoretically it is much harder to implement than instant gas release. | |||

[[File:Exp2 medium heat graph MODEL.png|center|thumb|493x493px|''Image 5.4.8: Graph of the heating experiment with heat gun set to 350 <sup>o</sup>C temperature, with different axis range;'']] | |||

[[File:Exp3 max heat graph MODEL.png|center|thumb|491x491px|''Image 5.4.9: Graph of the heating experiment with heat gun set to 550 <sup>o</sup>C temperature, with different axis range;'']] | |||

Finally, by changing the axis range of the original graphs of the heating experiment, it is possible to obtain graphs on images (5.4.8) and (5.4.9), which are much more handy to compare the experiment with the model, which is going to be introduced in the section 6. | |||

==== Cooling System Analysis ==== | |||

During our experiment a cooling system was also tested. Namely using compressed CO2 cartridges. The cartridges that were used, are usually used to pump up inflated tires on the go. They are small, light (in total 48 grams, which includes 16 grams of CO2), widely available and quite cheap. Therefore they would be quite ideal to use. They are made by pressurizing the CO2 to about 70 bars which increases the temperature to about 400 degrees Celsius. After this the gas is cooled down enough to liquify it (which will be around room temperature) and this liquid is stored in the cartridges. When one opens these cartridges the pressure abruptly changes and the liquid turns to gas and escapes rapidly. This change in pressure causes the gas to expand and cool off, because the gas that was already at room temperature is now taking up a lot more space, making it cooler. So all that needs to be done to rapidly cool the surrounding air is turn the nuzzle of the cartridge. | |||

This system seems to be very ideal, but a big downside is that since it is stored under high pressure it can be dangerous to heat it up. Generally, it is advised not to heat it above 50-55 degrees Celsius, which would be a big problem in the use case of fire robots. There could be a temperature sensitive valve that opens the cartridge (partly) if it gets too hot to keep the temperatures low but since 50 degrees is lower than what most of the electronics can handle (~75 degrees Celsius) it seems quite wasteful to try to keep the temperatures lower than necessary. The negative effects of the cartridge heating up too much are also too big to risk it, since this means the cartridge would explode and/or shoot away at a rapid speed due to the gas coming out very fast. | |||

In conclusion the cartridges do work to cool down the electronics as shown by our experiment, but unless the hazards that come with using them can be worked out, it does not seem like a viable option for a robot that has to deal with very high temperatures. | |||

==== Experiment Reflection ==== | |||

While the explement allowed to prove that a composite made from the chosen materials indeed can be used as a heat shield and can increase the lifetime of a robot inside a building on fire from 3 to 5 times, some aspects of the experiment could be improved. | |||

First of all, our temperature sensors had a limit of 125 Celsius degrees, above which the sensors could have been damaged. Hence in graphs (5.4.3), (5.4.4) and (5.4.9) the abruption of the "unprotected sensor" temperature is seen, as at that point operators removed the sensor in front of the heat shield for it not to get damaged. The experiment can be repeated with a more heat tolerant temperature sensors, or, for example, a pyrometer for monitoring the temperature of the steel sheet. | |||

Secondly, if you compare the experiment results and the data obtained from the model (section 6), you can see a significant difference in temperature rise rate behind two layers of insultation. The experimental setup was surrounded by room temperature air, which provided heat-loss from the sensors, while the model does not account for heat loss. In that sense the model is mush closer to the reality, as in a building on fire a robot is surrounded by hot air. We tried to minimize the effect of the air, by covering the sensors with yet another piece of insulation from the cold side. However, the temperature sensor "behind 2 layers of insulation" had less insulation from the room temperature air, in comparison to the sensor "behind 1 layer of insulation". Hence, the results from the experiment for 1 layer insulation are much closer to the model and to the true value, while the results for 2 layer insulation can be discarded. Adding a better insulation on the cold side of the set-up would result in more accurate results. | |||

=== Sensors & Image Recognition === | |||

When looking into different ways of detecting survivors, one specific method seems to pop up most frequently. These are UWB sensors, UWB standing for ultra-wideband. It is a form of radar sensing, using a different range of frequencies than normal radar sensors do. RADARS, short for Radio Detection and Ranging Systems, send out electromagnetic pulses. These pulses are reflected by objects and transmitted back to the sensor. This way the system can detect where the objects are [4]. | When looking into different ways of detecting survivors, one specific method seems to pop up most frequently. These are UWB sensors, UWB standing for ultra-wideband. It is a form of radar sensing, using a different range of frequencies than normal radar sensors do. RADARS, short for Radio Detection and Ranging Systems, send out electromagnetic pulses. These pulses are reflected by objects and transmitted back to the sensor. This way the system can detect where the objects are [4]. | ||

| Line 136: | Line 279: | ||

A different method might be the use of search algorithms to find potential survivors. Despite not going into the building, these search strategies show promising results in determining the locations of possible survivors if the map of the site is known [8]. This method might be less accurate than UWB, but it does not have to deal with high temperatures as it does not have to enter the building. The map of the site could be determined by getting footage from a drone. | A different method might be the use of search algorithms to find potential survivors. Despite not going into the building, these search strategies show promising results in determining the locations of possible survivors if the map of the site is known [8]. This method might be less accurate than UWB, but it does not have to deal with high temperatures as it does not have to enter the building. The map of the site could be determined by getting footage from a drone. | ||

After discussing with our team, it was concluded that the robot would need multiple sensors for different purposes. | |||

- UWB sensor: uses radar to detect motion, even as small as the breathing of a human. By comparing data on the general breathing pattern of humans with the found signal, a conclusion can be made on if there is a survivor near or not. This sensor can usually go through any material except for metals. | - UWB sensor: uses radar to detect motion, even as small as the breathing of a human. By comparing data on the general breathing pattern of humans with the found signal, a conclusion can be made on if there is a survivor near or not. This sensor can usually go through any material except for metals. | ||

| Line 146: | Line 290: | ||

- Temperature sensor: As creating a perfect heat shield is impossible and there are limits to what the electronics of the robot can handle, a temperature sensor can come in handy. The current temperature detected will be visible on the interface of the operator. So if the operator sees that the temperature keeps increasing as they proceed to go in a certain direction, the person controlling the robot knows to go a different way to protect the robot from unnecessary damage. | - Temperature sensor: As creating a perfect heat shield is impossible and there are limits to what the electronics of the robot can handle, a temperature sensor can come in handy. The current temperature detected will be visible on the interface of the operator. So if the operator sees that the temperature keeps increasing as they proceed to go in a certain direction, the person controlling the robot knows to go a different way to protect the robot from unnecessary damage. | ||

In order to properly implement these sensors, some things need to be known. The temperature range, power consumption, weight, and some other things are important. It’s very hard to find specifics for the general sensors, as the variables change per type/brand of sensor. Some research was done to find some specific sensors that seem suitable and they are presented with their properties below. | In order to properly implement these sensors, some things need to be known. The temperature range, power consumption, weight, and some other things are important. It’s very hard to find specifics for the general sensors, as the variables change per type/brand of sensor. Some research was done to find some specific sensors that seem suitable and they are presented with their properties below. | ||

| Line 157: | Line 303: | ||

- Novelda X4: This sensor comes in at a slightly higher price of about 80 euros. However, this is at a minimum quantity of a 1000 units, whereas the Qorvo can be ordered singularly. It has an operating range of about 10 meters maximum, dimensions similar to the Qorvo, voltage input of 1.8-3.3V and a temperature range of -40 up until 85 degrees Celsius. | - Novelda X4: This sensor comes in at a slightly higher price of about 80 euros. However, this is at a minimum quantity of a 1000 units, whereas the Qorvo can be ordered singularly. It has an operating range of about 10 meters maximum, dimensions similar to the Qorvo, voltage input of 1.8-3.3V and a temperature range of -40 up until 85 degrees Celsius. | ||

However, these sensors are designed to detect other UWB sensors and do not give a raw signal and are therefore not suited for this purpose. Sensors that are useable are extremely expensive and hard to get, therefore the testing of the sensors was not chosen as the focus of the project. | |||

=== Navigation & Algorithm === | |||

After our interview with the fire department we did more research and made design decisions regarding this aspect of the robot. From the interview conducted it is crystal clear that the robot should not be autonomous, but should instead be controlled by a human operator. As such three concrete methods of manual control were decided on by the team. In order of importance these methods are: | |||

=== | |||

From the interview conducted it is crystal clear that the robot should not be autonomous, but should instead be controlled by a human operator. As such three concrete methods of manual control were decided on by the team. In order of importance these methods are: | |||

# Full manual control | # Full manual control | ||

# PointCom aka ‘Google maps street view’ | # PointCom aka ‘Google maps street view’ | ||

| Line 243: | Line 362: | ||

The final challenge that was investigated (mostly before it was determined that the robot should not be autonomous) is the issue of self-guided navigation in an unknown terrain. For both of the chosen semi-autonomous navigation techniques we will need some path planning to be done by the robot. While there are many proposed solutions available for this issue<sup>[15][16][17][18]</sup>, I recommend using D* or D* Lite<sup>[15]</sup> as this is the same algorithm mentioned by reference<sup>[13]</sup>, and it has a detailed, well analysed and well explained (fairly simple) algorithm in reference<sup>[15]</sup>. | The final challenge that was investigated (mostly before it was determined that the robot should not be autonomous) is the issue of self-guided navigation in an unknown terrain. For both of the chosen semi-autonomous navigation techniques we will need some path planning to be done by the robot. While there are many proposed solutions available for this issue<sup>[15][16][17][18]</sup>, I recommend using D* or D* Lite<sup>[15]</sup> as this is the same algorithm mentioned by reference<sup>[13]</sup>, and it has a detailed, well analysed and well explained (fairly simple) algorithm in reference<sup>[15]</sup>. | ||

==== | === Communication Method === | ||

A firefighting robot needs to be able to communicate the information it is collecting back to firefighters that are either offsite or outside the fire environment. Research needs to be done on how to effectively and safely allow this communication to occur. | |||

The communication between the robot and the firefighters needs to allow data, possibly video and audio data, to be sent from the robot to a computer wirelessly. This one way communication is the bare minimum for our prototype to function, however depending on how autonomous we decide to make our robot it may be necessary to also send commands back to the robot, instructing it what actions to perform and how and where to move. | |||

Below are a variety of researched and analyzed methods and a corresponding article showing an example of how the technology is used in a similar system. One of the following will be chosen as the most appropriate method for our prototype. | |||

TCP/IP: [21] | |||

Bluetooth: [22] | |||

ZigBee: [23] | |||

MQTT: [24] | |||

ROS: [25] | |||

Following our user study consisting of an interview with a firefighter, we narrowed down the scope of our robot considerably. The firefighter had informed us that they would not want the robot to be autonomous, but rather remotely controlled. Additionally, they requested visual feedback from the robot on a tablet operated by a fireman outside of the fire. | |||

With this additional information, we can narrow down the communication systems to be put in place in our prototype. | |||

When considering wireless communication between a drone and a tablet in a highly dangerous environment, communication delay is an important factor. The off-site firefighter will be remotely ensuring the drone not only moves to where they desire, but also ensuring the drone can avoid flames, navigate gusts of steam, and dodge falling debris. For this to go smoothly communication delay must be at a minimum. | |||

Researching how to minimize delay lead to the conclusions that the most important factors are a low latency connection, minimizing data transmission, using real time operating systems, and optimizing control algorithms. | |||

After reading multiple scientific articles I’ve excluded Bluetooth and decided radio transmitter data-links are the preferable method both to control the drone and to stream video data back to the firefighter controlling the drone. | |||

=== Transportation === | |||

The robot that is going to be designed in this project needs a way of transportation. Robots in general have a lot of ways to transport like walking, rolling or a snake like movement. To determine what is best in the case of a fire rescue robot, pros and cons of each transportation method are needed to evaluate the best possible option. It is also important to keep in mind the environment that the robot operates in, since the robot needs to be able to face a challenges in encounters, such as fire and falling debris. | The robot that is going to be designed in this project needs a way of transportation. Robots in general have a lot of ways to transport like walking, rolling or a snake like movement. To determine what is best in the case of a fire rescue robot, pros and cons of each transportation method are needed to evaluate the best possible option. It is also important to keep in mind the environment that the robot operates in, since the robot needs to be able to face a challenges in encounters, such as fire and falling debris. | ||

| Line 350: | Line 479: | ||

There are a few different ways a robot can move itself, like walking, rolling, slithering or flying. Each of these methods has its ups and downs and can be considered in the design. It is a matter of discussing which method would be the best fit for our requirements and how this method influences the other components of the project. A solution for deploying the robot by the fire department is also needed. | There are a few different ways a robot can move itself, like walking, rolling, slithering or flying. Each of these methods has its ups and downs and can be considered in the design. It is a matter of discussing which method would be the best fit for our requirements and how this method influences the other components of the project. A solution for deploying the robot by the fire department is also needed. | ||

Week 3: Decide which method is most appropriate for our design | |||

''Deliverables: Concrete decision with justification'' | ''Deliverables: Concrete decision with justification'' | ||

| Line 375: | Line 505: | ||

All transportation methods were put under a microscope and it was quickly discovered that the robot would either fly or drive. Flying a robot inside a building is quite a risk, especially if the pilot is not experienced. Because of this risk and complication, driving will be the main transportation method. In more detail, tracks are going to be used to drive. Tracks are durable and able to drive over obstacles. The next step is to realize this transportation method. | All transportation methods were put under a microscope and it was quickly discovered that the robot would either fly or drive. Flying a robot inside a building is quite a risk, especially if the pilot is not experienced. Because of this risk and complication, driving will be the main transportation method. In more detail, tracks are going to be used to drive. Tracks are durable and able to drive over obstacles. The next step is to realize this transportation method. | ||

'''Week 4: Change of plans''' | |||

In the meeting it was discussed that choices have to be made in order to narrow down the scope of this project and actually create some deliverables. Initially it was planned to design a full robot with its software, but that will take too long. Instead, existing robots could be used as a base where additional hardware can be installed on. | In the meeting it was discussed that choices have to be made in order to narrow down the scope of this project and actually create some deliverables. Initially it was planned to design a full robot with its software, but that will take too long. Instead, existing robots could be used as a base where additional hardware can be installed on. | ||

| Line 388: | Line 520: | ||

To conclude, the focus of this project has steered into the materials and fire resistance of the system. That means that more research will go into how a robot can be protected in a harsh environment like a burning building. The findings from this research can than be used to improve a robot like Spot in order to perform rescue operation alongside the firefighters. | To conclude, the focus of this project has steered into the materials and fire resistance of the system. That means that more research will go into how a robot can be protected in a harsh environment like a burning building. The findings from this research can than be used to improve a robot like Spot in order to perform rescue operation alongside the firefighters. | ||

=== '''Users research''' === | |||

'''Week 2 + 3 interview fire department:''' | |||

'''Introduction interview:''' | '''Introduction interview:''' | ||

| Line 512: | Line 571: | ||

The firedepartment also currently uses heat cameras to assist in the search of people but mostly the core of the fire. In addition to that bigger departments also have a drone team, however these drones mainly focus on flying around the perimeters of the building and do not actually go inside. | The firedepartment also currently uses heat cameras to assist in the search of people but mostly the core of the fire. In addition to that bigger departments also have a drone team, however these drones mainly focus on flying around the perimeters of the building and do not actually go inside. | ||

Week 5 + 6: Interview with Danny Hameeteman | |||

'''Introduction interview:''' | '''Introduction interview:''' | ||

| Line 523: | Line 583: | ||

'''Questions:''' | '''Questions:''' | ||

# Which robot is more appropriate for fires, jens or spear, and why? What are the differences between the two? | # Which robot is more appropriate for fires, jens or spear for our use case, and why? What are the differences between the two? | ||

# What are its mobility limits? And how much load can it carry? | # What are its mobility limits of these robots? And how much load can it carry? | ||

# How were user requirements implemented? | # How were user requirements implemented? | ||

# How do user requirements differ per hazardous situation and how does this impact the design? | # How do user requirements differ per hazardous situation and how does this impact the design? | ||

| Line 530: | Line 590: | ||

# What sensors are used and why? | # What sensors are used and why? | ||

## It seems the robot mostly gets video footage, are there any other ways that could be interesting to create better environmental awareness? | ## It seems the robot mostly gets video footage, are there any other ways that could be interesting to create better environmental awareness? | ||

# What type of materials are used to make the robot more heat resistant? | |||

## What type of coating is used? | |||

## How expensive/difficult is this to implement? | |||

## Are there other options you would recommend (more suitable for our project)? (What about galvinized steel?) | |||

# What are the limits in terms of temperatures, potential damage etc? | # What are the limits in terms of temperatures, potential damage etc? | ||

## How is | ## How is the robot able to reach these limits? | ||

# Have any of the robots been applied in real life situations so far or just lab testing? How have the results been? | # Have any of the robots been applied in real life situations so far or just lab testing? How have the results been? | ||

# In the promotional video it is mentioned you can throw the robot, what are the benefits of this? | # In the promotional video it is mentioned you can throw the robot, what are the benefits of this? | ||

# Are there any other things we did not discuss that you think could be interesting for our project? | # Are there any other things we did not discuss that you think could be interesting for our project? | ||

'''Closing interview:''' | |||

Thank you for answering all our questions, this will really help us to design a robot that will be as useful as it can be. If you have any further questions, do not hesitate to contact me. This is the end of the interview. (and I will end the recording now) | |||

'''Summary/findings:''' | |||

It turned out the expert was not yet looking into heat shields or any way of making the robot more heat resistant. This means there is an opening for us to make recommendations about this during this course. The main constraint our solution has to take into account is weight. The expert was very clear that people did not want to use the device if was not very light weight. The second important constraint is of course cost, if the solutions is very expensive the fire department will probably not find it a worthwhile investment or not even be able to afford it at all. There was not a clear limit given in additional costs but there was a limit on weight, namely 300 grams. The robot now is 1.2 kg and it should not be more than 1.5 kg. Therefore we will try to find a solution that is under 300 grams and as cheap as possible. The maximum temperature that the robot can handle is about 85 degrees. Another notable thing that the expert mentioned is that because their robot is so low to the ground, they actually do not encounter big difficulties with visibility in a room with a lot of smoke. Additionally he advised that we either focus on improving situational awereness with a teleoperated robot or we focus on an autonomous robot that looks for people. Since we now mostly narrowed our focus to the heat shield, this is not extremely important for us anymore but it is still worth mentioning. | |||

== '''The Model''' == | |||

The experiment that was conducted gave insides into the heat transfer through the chosen materials. It has shown how the temperature changes and to what extend the temperature increases over time. A theoretical model is also created that will simulate the experiment. The purpose of this model is to see how accurate the temperature can be estimated. This estimation can help to do further predictions with the model, i.e. increasing/decreasing certain parameters, that can help with making design choices in the future. | |||

'''Creation of the model''' | |||

The model makes use of a ordinary differential equation which takes different thermal resistances and heat capacities into account. The thermal resistances used are those of convection through the layer of air, conduction through the galvanized steel, and conduction through the insulation. All of these thermal resistances have been calculated separately with the appropriate values for each of the materials, these are then added up to get the total thermal resistance that is to be used in the ODE. | |||

The heat stored in these layers and their temperatures due to this heat have been calculated as well, by multiplying the mass of each layer with the specific heat capacity of their respective materials. | |||

The area that is directly heated by the heatgun is very small, but eventually a bigger area of steel and insulation will heat up as well. This has been implemented in the model by starting of with the small area directly heated as the initial value and then slowly increasing the area used in the ODE over time. This makes the model more accurate than just assuming the heat is distributed evenly over the entire area of the galvanized steel plate and insulation that were used in the experiment. However, this assumption is only added to make the model more accurate when comparing with the experiment done, but not for a realistic case. If the material really would be placed in a fire, the heat would come from all directions, thus making the assumption that the entire material heats up simultaneously would be the accurate choice. | |||

As the heater was turned off after 300 seconds during the experiment, the model also plots the temperature over 300 seconds to make a clear comparison. As there were three temperature sensors place during the experiment, the temperature values for each of these locations were plotted as well. These locations are: before the steel plate, after one layer of insulation, and after a double layer of insulation. | |||

If the model can be deemed reliable enough for the situation replicated during the experiment, other useful predictions can be made as well. By changing the values set at the beginning of the model, the temperatures can be plotted for other circumstances too. For example how the temperature increases when the heat supply is doubled or the layer of steel is made thinner. | |||

'''Validation of the model''' | |||

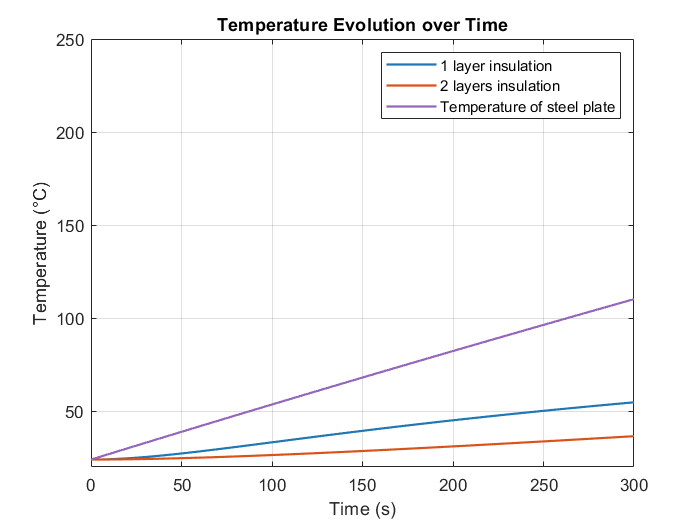

'' | The model as well as the results of the experiment have been gathered, which means that it can now be determined how well the model functions. In the figure below, the model results can be seen which can be compared to the results of the experiment. During the experiment, a continuous heat source was pointed at the materials for 300 seconds. At that time, it can be seen that the temperature behind the steel plate of 0.75 mm and a ceramic fiber layer of one cm is 62.60 degrees in the model and 65.94 degrees in the experiment. If the ceramic fiber layer is doubled, the temperatures become 39.74 and 31.50 degrees, respectively. This is a mean error percentage of about 5% for one layer and 20% for two layers. | ||

[[File:Model results.png|center|thumb|Temperature evolution over time of the model.]] | |||

The reasons for the bigger deviation between one and two layers of ceramic fiber are mainly caused by the assumptions made in the model. The connection between the first layer of ceramic fiber to the steel and the second layer of ceramic fiber to the first layer is not identical. There could be a layer of air in between the layers during the experiment that has not been accounted for in the model. Also, it is assumed that the heat from the first layer will travel in its entirety to the second layer, which is not fully accurate since there is a small amount of heat loss at that moment. This means that the model is most accurate at small deviations of the parameters and will get less accurate when the thicknesses of the materials are increased on a centimeter scale. | |||

'''Further predictions''' | |||

One of the main limitations to a fire resistant robot is its weight. This has been established during the interviews. Because one of the materials is galvanized steel, it would be best to keep the layer of steel as thin as possible. The model was used to analyze what would happen with the heat transfer with different thicknesses of steel. As a result shown in the figure below, it can be seen that the final temperature is only slightly lower with a 1 cm steel layer opposed to a layer of 0.75 mm, which can already be seen in the figure above. This means that the steel layer is not much involved in the heat transfer which means that this layer can be as thin as possible without bringing difficulties to the heat resistance. To find out what the best thickness would be will thus only rely on the structural support it will need to give to the robot. | |||

[[File:Increased steel.png|center|thumb|Temperature evolution with increased steel layer, from 0.75 mm to 1 cm.]] | |||

To finalize, the model is used to simulate the experiment. It was found that the model comes quite close to the real data which means that it can be used to make accurate predictions. For instance, the galvanized steel plate is a good heat conductor which means that the heat can transfer easily through the steel. This means that the steel plate can be as thin as possible to cut some weight. The ceramic fiber insulation is thus the most important component in the heat transfer and should be used extensively in the design of the robot. | |||

== '''Conclusion''' == | |||

We started off this project with the goal of designing a robot that could aid firefighters in detecting trapped survivors in a fire. During the course of the project, we worked with both firefighters and robotics entrepeneurs, realising that the technologies we were researching and designing could be helpful in an even wider scope. After eight weeks we have delivered substantial results in regards to the design of a robot that can enter a fire and detect survivors, as well as successful results in multiple experiments regarding the thermal regulation and cooling of such a robot that accurately correspond with predicted mathematical models. | |||

While the construction of our robot and implementation of our findings were outside of the scope of this eight week project, we are satisfied with our results and would be thrilled to see them be used in future studies, designs or experiments. For the users that we focused on, we may not have a final product to deliver to the firefighters, but we have delivered interesting findings with regards to the fiberglass insulation and gas cooling system that our second user, Danny Hameeteman, co-founder of Sita Robotics, can take into consideration with his plans for future improvements for his situational awareness robots. | |||

We encourage anyone interested in our work and who wants to pick up where we left to do so. | |||

== '''Recommendations''' == | |||

To get better results for the experiment, longer measurements could be taken to get a clearer picture on how the temperature evolves in the long run. Furthermore, the same amount of insulation and other materials present should be on the other side of the sensor as well, to get more realistic heat loss results. | |||

These heatlosses are currently considered to be minor in reality, as in a fire the heat would come from each side. For this reason, the heatlosses have not been implemented in the Matlab model, but this heat flow from all sides should be added in the future to get a more accurate model. | |||

== '''Literature:''' == | == '''Literature:''' == | ||

=== References === | |||

[1] - V. Etacheri, R. Marom, R. Elazari, G. Salitra, and D. Aurbach, “Challenges in the development of advanced Li-ion batteries: a review,” Energy Environ Sci, vol. 4, no. 9, pp. 3243–3262, Aug. 2011, doi: 10.1039/C1EE01598B. | [1] - V. Etacheri, R. Marom, R. Elazari, G. Salitra, and D. Aurbach, “Challenges in the development of advanced Li-ion batteries: a review,” Energy Environ Sci, vol. 4, no. 9, pp. 3243–3262, Aug. 2011, doi: 10.1039/C1EE01598B. | ||

| Line 608: | Line 710: | ||

[28] [https://link.springer.com/article/10.1007/s40595-018-0117-9 Evaluation of educational applications in terms of communication delay between tablets with Bluetooth or Wi-Fi Direct] | [28] [https://link.springer.com/article/10.1007/s40595-018-0117-9 Evaluation of educational applications in terms of communication delay between tablets with Bluetooth or Wi-Fi Direct] | ||

=== State of the art review | === State of the art review === | ||

[https://robomechjournal.springeropen.com/articles/10.1186/s40648-022-00229-5 Novel exterior cover design for radiant heat resistance of firefighting robots in large-scale petrochemical complex fires | ROBOMECH Journal | Full Text (springeropen.com)] | [https://robomechjournal.springeropen.com/articles/10.1186/s40648-022-00229-5 Novel exterior cover design for radiant heat resistance of firefighting robots in large-scale petrochemical complex fires | ROBOMECH Journal | Full Text (springeropen.com)] | ||

| Line 824: | Line 926: | ||

== Appendix == | == Appendix == | ||

=== '''Appendix A''' === | === '''Appendix A (Time spent table)''' === | ||

{| class="wikitable" | {| class="wikitable" | ||

| colspan="3" rowspan="1" |Week 1 | | colspan="3" rowspan="1" |Week 1 | ||

| Line 859: | Line 960: | ||

For weeks 2-7 refer here: https://docs.google.com/spreadsheets/d/1G5tPp-6NsQBCDB8bOLenNYROfXyhWo69ukwcyu0_uLk/edit?usp=sharing | For weeks 2-7 refer here: https://docs.google.com/spreadsheets/d/1G5tPp-6NsQBCDB8bOLenNYROfXyhWo69ukwcyu0_uLk/edit?usp=sharing | ||

=== | === Appendix B (Transcript interview fire department) === | ||

'''Interviewer:''' The product we are designing is intended to help firefighters and firefighters and it is going to do that by finding people find people in a building that is on fire and report that so they can search more specifically. Exactly how this is going to work we are working on now and for that your answers are very important. Do you have any further questions? | '''Interviewer:''' The product we are designing is intended to help firefighters and firefighters and it is going to do that by finding people find people in a building that is on fire and report that so they can search more specifically. Exactly how this is going to work we are working on now and for that your answers are very important. Do you have any further questions? | ||

| Line 1,027: | Line 1,094: | ||

'''Interviewer:''' Okay that's fine. That was basically all the questions we had prepared. Again thank you very much and I will now turn off the recording. | '''Interviewer:''' Okay that's fine. That was basically all the questions we had prepared. Again thank you very much and I will now turn off the recording. | ||

=== Appendix C (Transcript interview technical expert) === | |||

'''Interviewer 1:''' Which robot that is developed by your company is more appropriate for fires? The jens or spear'''?''' | |||

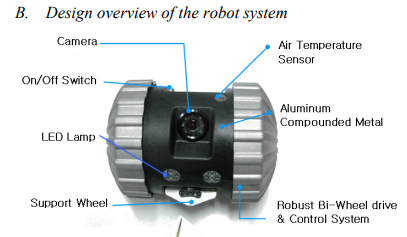

'''Interviewee:''' So indeed a small background maybe, I am one of the founders of SITA robotics. It is a company we try to develop robotics for accessible solutions for police fire departments those kind of applications. So what we have done so far is two projects, one of which is for the ministry of defensive where we developed the spear robot. That is a two wheeled system that you can easily throw into a building and do some research there, it is teleoperated, it has a controller with that so that you can easily have access to what’s happening inside the building. Aside from that we developed jens, which is a four wheeled system, it has a similar concept the only difference is that you can more easily overcome obstacles. Take some extra weight, workload, with you for extra sensors. That one is more specified for inspection purposes I would say, so there is no time sensitive operation. So have the best operation instead of optimize for the shortest time, so in that sense I would say the spear robot, so the two wheeled system, is the more appropriate one. Aside from that we are now also developing a device which is not a robot but a remote “sensor ball”, which is basically a system, you can roll it into a building which gives you information about gas, a camera, sound stuff like that. Actually today there is an article in the Telegraaf about our robot. So that’s another project that is currently running. | |||

'''Interviewer 1:''' What are the mobility limits of this robot? And how much load can it carry? | |||

'''Interviewee:''' So in this case I think we should focus on the two wheeled system, because that is really used for time sensitive operations. Its able to drive over relatively flat grounds, small obstacles are doable, up to like 6 cm or so, that is about the limit. What typically happens is they know there is something happening on the other side of the wall, but they cannot go there easily, because they don’t want to air going in there as well, so they would like to have some sort of extra camera sight on that location. Especially robustness and trackability is important in that sense. | |||

'''Interviewer 1:''' Okay, and how did you implement user requirements when you developed the first and maybe the second robot? | |||

'''Interviewee:''' So when talking to clients, you typically hear they want everything but they have a very limited budget, so in that sense we are trying to peel down what is actually of most importance. One of the first spec sheets we got, was we want a 4K camera system on the robot, then we come with a 720p which is far far lower that the 4K that they expected and we get compliments on the quality of the screen. We really try to understand if its actually needed what they are asking for. So why do you want to have 4K, because they want to see what is 3 meters away and specify towards that instead of implement whatever is said by the user. With money you can probably do everything but then you have really inaccessible expensive system that no one is going to use anyway. So that is a really big trade off. | |||

'''Interviewer 1:''' You also mentioned that you not only develop robots for military but also for other emergency services, how do used requirements differ there? | |||

'''Interviewee:''' So they are all different, at least they say, so the result that you obtained can be different, because in a military situation typically your life is at stake, but typically in a swat team it is more that they already know what will happen inside, they just want a confirmation. So it seems different but the solution that we proposed fits their situations quite nicely. Sorry what was the question again? | |||

'''Interviewer 1:''' How do the user requirements differ? Or you’re trying to come up with some ultimate solution that fits many? | |||

'''Interviewee:''' No not so much, but we try to minimize it so that it fits the basic needs for each of them, so for instance a gas sensor that might be really relevant for a fire department but for a swat team not so much. So its not in the basic product. | |||

'''Interviewer 1:''' What are the main obstacles for this type of robots? | |||

'''Interviewee:''' Like physical obstacles? | |||

'''Interviewer 1:''' No like obstacles that would prevent someone from using it. | |||

'''Interviewee:''' Yeah so in the end it is mainly the intuitiveness, so if they are not used to using those systems which you typically see because they are not trained for those systems, or maybe one guy out of twenty that is trained. So for us its really the intuitiveness, we really try to make it so that you pull the pin and it starts and you can already directly have sight on your screen, that makes it easier to implement. Though it is still a peoples game in that sense, its definitely not only the technology. | |||

'''Interviewer 1:''' Apart from specific sensors, like co2, which sensors are used? It seems that the robot mostly gets video footage, are there any other ways to get better environmental awareness? | |||

'''Interviewee:''' Yeah so, two other elements that we are experimenting with is thermal information and acoustic information. You can see a lot from acoustic noise, sound, and also from temperature difference. So each fireman is trained with a thermal gun, so that they can check okay is the handle too hot to grab or is there something behind it? So I think those two really benefit your “sixth sense”. | |||

'''Interviewer 2:''' So you use the acoustic gun for echo’s? | |||

'''Interviewee:''' Yes or if there is a gas leak. You can visualize the difference in sound. | |||

'''Interviewer 1:''' I also wanted to ask, if the visibility is really low, the room is covered in smoke for example, then you get barely anything for the camera. Would then ultra sound be useful? | |||

'''Interviewee:''' So I know there have been researches on radar sensors that work quite well in smoke, although radar sensors in general are still quite clumsy so not suitable for our situation. The way we are handling the smoke part is that we are really low to the ground. Smoke elevates so we have not much interference from this. Usually they will not enter a room that is so filled with smoke but if they do they are trained to go low to the ground to see the exit for instance. | |||

'''Interviewer 1:''' Ah that’s really interesting, so are there any materials used for the robot coating that are heat resistance? | |||

'''Interviewee:''' No, that is one of the user requirements that we did not take into account. Because we believe that the accessibility part is more important than that is not melting or burning when it is to close to the fire. Also you should think of, how close do you actually need to be to the fire to actually get your information? Of course I would be really interested to hear what you have come up with but that is maybe for later. | |||

'''Interviewer 1:''' So it is not high heat resistant. Does it have any cooling systems? | |||

'''Interviewee:''' No also not. We have a small fan, that is mainly for trying to create a circulation through our sensors. But they do not really heat up that much, we can do it by just dissipating over the metal. | |||

'''Interviewer 1:''' That’s good, what would be the limits of the robot regarding temperature? | |||

'''Interviewee:''' I do not know what we said exactly but I would say around 85 degrees it would become a problem. And the lowest I would say around -10 degrees. But it mainly depends on your battery. | |||

'''Interviewer 1:''' Have any of these robots you told us about been applied in real life situations? Or just lab testing? And would your clients that have classified information share the performance of the robot with you? | |||

'''Interviewee:''' So yes we have a couple of prototypes running. Mainly one that are being used in the police case. Not the fire department case yet, because we are still on the part of the development. And yes we do get information back from them, and how the experience is. Especially the things that could be applied to our next product. So what we did with the jens system, we brought it to a lot of police stations for a month and then obtain the results. So the testing we do for free and then we use the results. | |||

'''Interviewer 1:''' And what would be the most important take away message from this test? | |||

'''Interviewee:''' Of course you have a lot of technical things, like it would be nice if the camera could rotate. So for us the technical things are a side effect to understand if its actually valuable to their operation because if you here about a lot of features that need to be added, then it’s the questions whether it has the added value that they think and we think. So it is more about that to understand whether we need to pursue things or there’s no problem solution fit. So it is more about that, not so much about the technical results. | |||

'''Interviewer 1:''' You also mentioned that you were able to throw the spear, what are the benefits of that? | |||

'''Interviewee:''' The four wheel system you just need to put down, so if there is small stairs you already need to get up those which makes you vulnerable. So it is easier to go into places you don’t want to yet. Its also easier if you cleared the ground floor and you want information about the first floor, you can throw the robot up the stairs. So that you don’t expose yourself to early, as well for vulnerability as for element of surprise being gone. | |||

'''Interviewer 1:''' Can this robot handle rolling down the stairs? | |||

'''Interviewee:''' We did some testing on that, its successful, but of course things can damage. | |||

'''Interviewer 1:''' Because I think it would be a cool combination with a drone to throw in on the top floor and as soon as it is done with the top floor it goes down by the stairs. Have you thought about this? | |||

'''Interviewee:''' We were at a swat team training and they used a helicopter to drop it down on a building and then it swept down like you just explained, so that would definitely benefit their situation in my opinion. | |||

'''Interviewer 1:''' Since your robot is not very heat resistant, would you consider outsourcing the development of a heat shield for your robot? | |||

'''Interviewee:''' I am not sure if it is the most critical element of this robot yet. Because I’m not sure whether it will be used in those situations. They are using drones already in the building already, but not when the fire is at its most, cause then they are just focusing on containing the fire. So to be honest I don’t think so, and the main reason for that is you are adding additional costs for a feature that is not used so much yet. Until shown otherwise, so if from the next ten robots we deliver nine will burn in less than a month then we know, but id rather do it like that than double the price of the product when it might not be necessary. | |||

'''Interviewer 1:''' But if you imagine for a second that you are in sudden need for a coating, what would be your requirements be in terms of weight, elasticity and thickness for instance. | |||

'''Interviewee:''' My first view is indeed some sort of painting coat around it that is able to reduce the time it takes for the heat to go inside. In terms of weight, our two wheeled system is 1.2 kilo now so it cannot be more than 300 grams for this. and that is not because the robot is not strong enough, but it is because the fire brigade has to where the robot itself. The first robot we came in with was 2.5 kilograms and they said that’s a nice idea but it is too clumsy and too heavy to actually put this on our belt and take it with us. They have a lot of stuff on their body already. So in the military they say all the new things should be more light weight that what we now have. Fight light is their main mission right now, and I can only imagine that this is the same for the fire departments. | |||

'''Interviewer 1:''' Are there any other things that were not discussed but you think could be interesting for our projects? | |||

'''Interviewee:''' In the fire departments operation are two phases and the first phase is okay we come in and barely have an idea of what is happening in there and that is the most crucial phase to get information from the inside, because five minutes is quite long for a dynamic situation like that. And the second part where they do more of a monitoring and sustaining phase, those situations are way more suitable for an autonomous robot, but I wouldn’t try to combine those into one. | |||

'''Interviewer 2:''' But if I understand correctly you are saying either focus on remote controlled and improving situational awareness or autonomous and finding people? Or am I not understanding that correctly? | |||

'''Interviewee:''' Yes, and about this finding people part, even though they say there are not trained for this anymore if they know there is people in there, they are going to save them. They are trained to not take risks but, especially if there is kids inside, it is that above anything. So in that case there is no time for a teleoperated device anyway. | |||

'''Interviewer 2:''' Oh that’s interesting because when I talked to the fire department they indeed said first control the fire and then they swoop. | |||

'''Interviewee:''' Yes, but than they know that there’s no human in danger. Because i also spoke to a fireman and they said there was a house fire and a mother and the son were trapped on the ceiling and then they just make sure to get there. But those are only one or two time event for a fire department that does not happen on a weekly basis. So even though the fire department sound like they’re saving lives, their main job is to contain the fire and make sure other buildings are not damaged. | |||

'''Interviewer 2:''' And have you heard about differences between houses or buildings like atlas, office buildings? | |||

'''Interviewee:''' Yes. | |||

'''Interviewer 1:''' We thought because there are a lot of people in atlas they will not evacuate in time, especially knowing they are students and would be sleeping maybe. | |||

'''Interviewee:''' Indeed, its quite different because with bigger buildings especially, you can also think of elderly houses because they are stubborn, they do not hear the sound. Typically when such a fire comes in they scale up with more cars already. Typical housefires are not that exiting usually. So the bigger buildings are usually closer to their hero image. Because you also get extra layers of communication there, there is an extra officer of demand, the press needs to be there. By scaling up to three or four cars it already becomes more complicated. | |||

'''Interviewer 2:''' Okay thank you for answering all of our questions, this will really help us design the robots as useful as it can be. If you have any further questions please do not hesitate to contact me, and I will stop the recording now. | |||

=== Appendix D (Informed consent forms) === | |||

=== Appendix E (Matlab script) === | |||

clear all | |||

% Constants | |||

q_heatgun = 2000; % Constant heat source (W) | |||

T_ambient = 24; % Ambient temperature (°C) | |||

A = 0.25 * 0.5; % area plate (m^2) | |||

A_heatgun = pi*(0.02^2); % Area of hot air coming out the heatgun (m^2) | |||

% Material properties | |||

c_air = 700; % Specific heat capacity of air (J/(kg*K)) | |||

x_air = 0.15; % Thickness of air layer (m) | |||

rho_air = 1.17; % density air | |||

V_air = 3; % taking into account that heat will dissipate over more air than just the air between the heat gun and steel | |||

m_air = rho_air * V_air; % Mass of air (kg) | |||

h_air = 16; % Convective heat transfer coefficient for air to steel (W/(m²*K)) | |||

c_steel = 420; % Specific heat capacity of steel (J/(kg*K)) | |||

x_steel = 0.01; % Thickness of steel plate (m) | |||

rho_steel = 8000; % Density of steel (kg/m³) | |||

m_steel = rho_steel * x_steel * A; % Mass of steel plate (kg) | |||

k_steel = 60; % Thermal conductivity of steel (W/(m*K)) | |||

c_ceramic = 1000; % Specific heat capacity of ceramic (J/(kg*K)) | |||

x_ceramic = 0.01; % Thickness of ceramic (m) | |||

rho_ceramic = 800; % Density of ceramic (kg/m³) | |||

m_ceramic = rho_ceramic * x_ceramic * A; % Mass of ceramic (kg) | |||

k_ceramic = 0.12; % Thermal conductivity of ceramic (W/(m*K)) | |||

% Thermal resistances | |||

R_conv_air = 1 / (h_air * A); % Convective thermal resistance from air to steel outer surface (K/W) | |||

R_cond_steel = x_steel / (k_steel * A); % Thermal resistance of steel (K/W) | |||

R_cond_ceramic = x_ceramic / (k_ceramic * A); % Thermal resistance of ceramic (K/W) | |||

% Ratio of steel plate actually being heated | |||

ratio = A_heatgun/A; | |||

% Ratio becomes bigger over time because the heat spreads over the plate | |||

ratio_function = @(t) ratio * (1 + 1*t/300); % Ratio increases by 100% over 300 seconds | |||

% Total resistance through insulation | |||

R_total = (R_conv_air + R_cond_steel + R_cond_ceramic); | |||

% Total heat capacity | |||

total_heatcapacity = m_ceramic * c_ceramic + m_air * c_air + m_steel * c_steel; | |||

% ODE Function with updating ratio | |||

%ode_temperature = @(t, T) (q_heatgun - (T - T_ambient) / (R_total * ratio_function(t))) / total_heatcapacity; | |||

ode_temperature = @(t, T) (q_heatgun * (1 - 1 * exp(-0.015 * t)) - (T - T_ambient) / (R_total * ratio_function(t))) / total_heatcapacity; | |||

% 1 - 1 * exp(-0.015 * t), This models the heat transfer more accurately | |||

% and makes it more of a quadratic line | |||

% Time span for simulation | |||

time = linspace(0, 300); % From 0 to 300 seconds | |||

% Solve ODE | |||

[t, T] = ode45(@(t, T) ode_temperature(t, T), time, T_ambient); | |||

% Plotting | |||

figure; | |||

plot(t, T); | |||

xlabel('Time (s)'); | |||

ylabel('Temperature (°C)'); | |||

title('Temperature of the ceramic fiber cloth over Time'); | |||

grid on; | |||

Latest revision as of 20:38, 25 April 2024

Thermal regulation of a fire-rescue robot

Group Members

| Name | Student Number | Study |

|---|---|---|

| Storm Wilms | 1839993 | BME |

| Tessa Groeneveld | 1738941 | BPT |

| Abel Galambos | 1846647 | BCS |

| Elektra Katsikis | 1826654 | BCS |

| Roman Sinickis | 1748939 | BAP |

| Tessa Cuijpers | 1836927 | BME |

Introduction & Problem Statement

A fire in a residential building is a common and critical emergency in any big urban area. Apart from the damage it does to the building, there are often people stuck inside whose lives depend on how quickly they are found and rescued by the firefighters. Sometimes, when the emergency services arrive at the scene, the entry to the building is already blocked by fire. The first question that a firefighting crew has, is how many people are inside and where they are. If the entry is blocked, or there are other complications, the search and rescue procedures can only be started after it is safe to enter the building. This delays the rescue and decreases the chances of people trapped inside surviving with every second. Often this leads to either firefighters entering the house even when it is still dangerous, or people not getting rescued in time.