User interface & General considerations

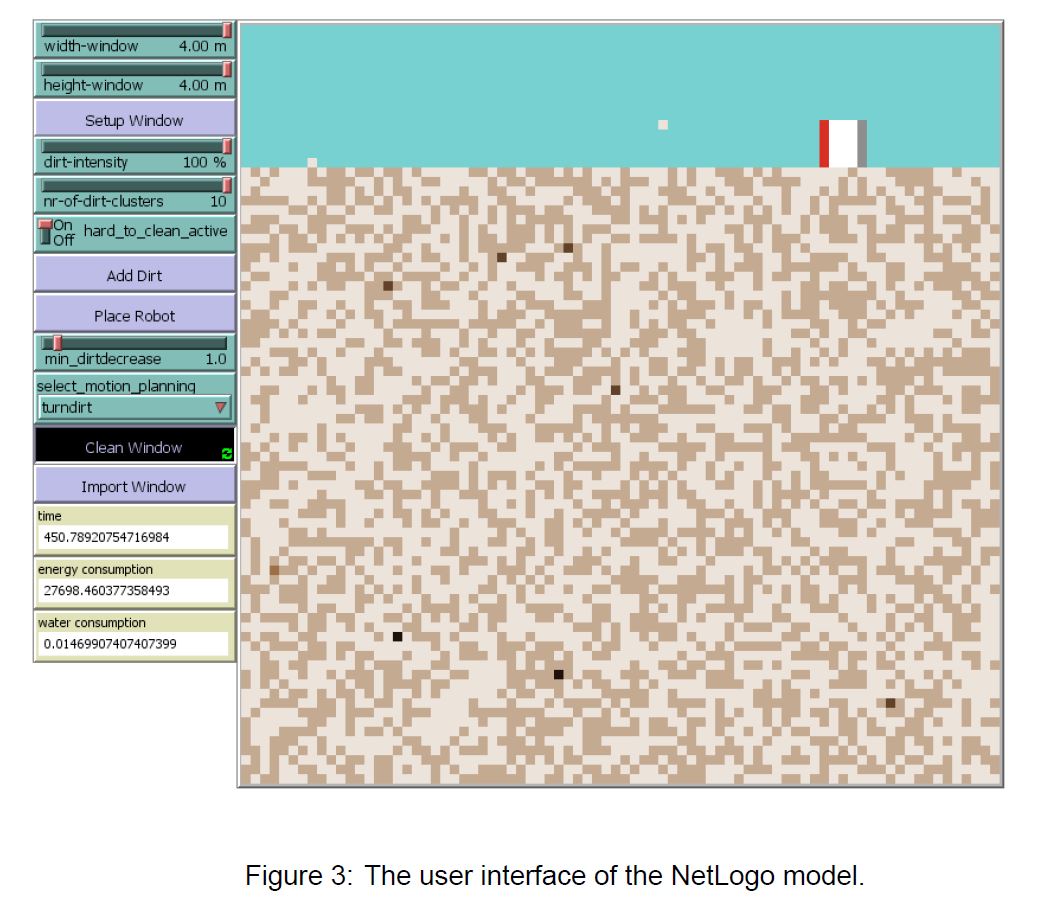

The first step in modeling the motion planning algorithm with NetLogo consisted of creating the

window with an adjustable dirt distribution that represents reality. The entire user interface including

the window and robot is shown in Figure 3 below. As mentioned before, a single patch from the

window represents an area of 50 x 50 mm. As can be seen in Figure 3, the dimensions of the

window can be adjusted by means of sliders. The width-window slider can be incremented with

250 mm which corresponds to 5 patches, while the height-window slider has an incrementation

of 250mmwhich corresponds to 5 patches. The reasons for these choices was already explained

in Section 'Design Choices'. When the sliders are moved, and the button Setup Window is pressed, the model

will adjust the amount of patches to the dimensions that are chosen. From a certain window size,

the patch size is adjusted slightly to make sure that the whole window fits on the screen of the

user of the model.

The above-mentioned dirt distribution is again modeled with the ideas as stated in Section 'The Window'

At the start of each run of the model, each of the patches will receive a value of dirtiness between

0 and 100 denoted with the variable dirt-level. The dirtiness value of patches is indicated

by the color of the patches. The darker the color of the patch, the higher the dirtiness value of the patch. When a patch is completely clean, its color changes to blue. The earlier mentioned

more or less even distribution of dirt will result in a random dirtiness value for all patches that

lies between 10 and 30. Subsequently, a number of patch clusters, which can be specified with

the nr-of-dirt-cluster slider, is selected from which the previously received dirtiness value is

overwritten with a random number between 40 and 100. Additionally, there is a dirt-intensity

slider included in the model. The value of this slider in % is divided by 100 and all the dirtiness

values of the patches are multiplied by this number. So, when a patch would receive a dirtiness

value of for instance 30 and the slider is at 50 %, the dirtiness value that the patch eventually

receives is equal to 15. As has been stated earlier, all patches are assigned a number that denotes

how hard it is to clean each of them. This number is obtained for each patch by taking

a sample from an exponential distribution with mean 1 and multiplying this value by 100. Next,

if the number is bigger than 1, it is set to 1. The resulting number is eventually stored in the

variable hard_to_clean for each patch. When the robot moves over patches, its dirt-reduction

will be multiplied with this number. Most of these patches will have a value for this number that

is equal to 1, which has no effect on the dirt-reduction. A small number of patches will get a

smaller number and are thus harder to clean. They thus require a lot more wiping motions to

fully clean them. The just explained hard to clean possibility for patches can be turned on or off

by means of a switch in the user interface denoted by hard_to_clean_active. Switching this

off, results in a state that all patches have a hard-to-clean value of 1, which means that this

variable has no effect anymore on the dirt-reduction of each patch. The dirt distribution is generated

with the button Add Dirt. Re-clicking the button results in a newly generated dirt distribution.

As has been mentioned previously in Section 'Cleaning', the modeled window cleaning robot keeps

track of the changes in dirtiness value of all patches. In the model this is done by storing not only

the current dirtiness value of a patch in the variable dirt-level, but also storing the previous

dirtiness value of a patch in the variable previous_dirt-level. The robot then compares the

previous dirtiness value with the current dirtiness value when it moves over a particular patch with

its cleaning section. When the reduction is smaller than a predefined standard, the patch is not

considered by the robot anymore. This predefined standard is set with the min_dirtdecrease

slider. The value of the slider is the minimum difference of the previous dirtiness value and the

current dirtiness value for which the robot will still consider the patch as a patch that needs to be

cleaned. The value of this slider is both used for the standard and the newly developed motion

planning algorithms.

Apart from the already mentioned elements of the user interface, there are still a couple of buttons,

monitors and one chooser that need to be explained. First, the Place Robot button places, as the

name would suggest, the robot on the window. It however always places the robot in the middle

of the window and not at a random position as has been stated earlier. This is done for a specific

reason. When the robot starts cleaning the window, which is initiated with the Clean Window button,

the robot first starts to move to the upper left corner for every programmed motion planning

algorithm. The time that it takes to reach this top left corner is also added to the total cleaning

time. To be able to compare the cleaning times of the considered motion planning algorithms with

each other in an objective way, it is thus necessary that this time to reach the top left corner is

always the same for all algorithms for a fixed window configuration. This is the reason for always

placing the robot in the same position. Additionally, this is also the reason for not taking the time

into account that the robot needs to turn at its initial place in the middle of the window to face the

upper edge of the window. The robot is namely always placed with a random heading direction.

To eliminate this source of randomness from the time that is necessary to move to the upper left

corner, the initial rotation time is thus not considered.

Another choice in the model that was made in order to be able to make an objective comparison

between the modeled algorithms was the choice for the implementation of the Import Window button.

With this button, it is possible to import a previously used dirt distribution again. This option

is necessary to test the considered motion planning algorithms on exactly the same conditions. It is a very welcome addition to the model, since there is a big factor of randomization included

in the dirt distribution which can be eliminated in this way when that is deemed necessary. This

button is also used to obtain the results presented in the Section 'Comparison'. To select a specific motion

planning algorithm for testing, the chooser select_motion_planning is used. The option

standard denotes the reference algorithm, zigzag denotes algorithm 1 and turndirt denotes algorithm 2 as described in 'algortithm 2'. The monitor time keeps track

of the time that it takes the robot to clean the window. The monitors energy consumption and

water consumption keep track of the energy consumption respectively the water consumption of

the robot during the cleaning of the window.