PRE2020 3 Group3

Robots in Horeca

Group Members

| Name | Student ID | Department | Email address |

|---|---|---|---|

| Marvin Thüne | 0916148 | Applied physics | m.p.thune@student.tue.nl |

| Isidoros Kotinis | 1286692 | Applied physics | i.n.k.kotinis@student.tue.nl |

| Lotte van Megen | 1453092 | Psychology and Techonology | l.m.v.megen@student.tue.nl |

Introduction

Everyone is missing the horeca during these corona times. All the hotels, restaurants, and bars have been closed for quite some time now. And of course, we are all missing it and would like to go back rather sooner than later. We would all like to enjoy the warm weather again while drinking a beer at an outdoor cafe.

So did we, and that is how we discovered Horeca robots. As everyone was trying to find solutions to open their restaurants safely again some people had tried using these robots. [1] It seemed quite promising at first but it turned out that most robots weren’t developed enough for this work yet. Serving went quite slow and the whole system wasn’t very efficient yet. It turned out that there were still enough points that needed improvement before a restaurant could be run mostly by robots. Seeing the robots still had so many points of improvement we set this as our challenge: how can we improve these robots and most importantly their efficiency so they can properly work for a restaurant?

To discover the specific problems with these robots we had to find a stakeholder, someone who already worked and experimented with them. An interview with this stakeholder would give us more information about the different problems and how we could help to improve the robots. Our main stakeholder became Dadawan, after an interview with them about all the problems they had encountered we conducted an experiment that would help to solve some of their problems. Unfortunately, we didn't find a solution to open the horeca again, but who knows what will happen in the future. Maybe the next time we enjoy a beer on the terrace, it will be served by a horeca robot.

Problem statement and objective

At the beginning of this project we had different ideas on what we wanted to contribute to these existing horeca robots. The ideas below were our options after our state of the art research.

1. Design a specific situation where robots make it possible to open up Horeca that is hygienic enough to be able to open up during a pandemic. Robots will minimize the customer-staff proximity in the horeca.

2. Look at existing server robots in restaurants and try to improve their customer friendliness by improving their interaction with people and modifying their appearance. Mostly look at server robots, not the ones in the kitchen. Analyze which properties the robots should have.

3. Design a robot that helps people with a disability (or people that are forced to isolate due to medical reasons) to do work in a restaurant by letting them remotely control robots that walk around in the restaurant.

After some more research and an interview with stakeholders we have a better idea of how well the robots function and what needs more attention and what not. After that additional research we made a final decision to focus on improving the efficiency and pace of the robots. That is why, for this project we will look at the maximum speeds of the robot, and also conduct an experiment to see if the current speed could be improved. The objective is to let the robots go faster without causing more problems on other aspects like the emergency stop. Next to the speed improvement we also want to come up with additional suggestions and solutions on how to make the robots more efficient.

USE

- User

The main users are the employees of the restaurant, as the robots are mainly there to assist them. They can assist the staff by taking over some load of bringing the meals and in the future hopefully also drinks to the tables. The staff will be relieved from some of the physical work and it will also allow them to spend more time interacting with the customers.

- Society

Implementing robots into horeca can have a great impact on society. They are already widely being used in several Asian metropolises. The question is if this trend will also reach us and if it does, what it will mean for us. Of course, it will have an impact on the jobs in the horeca, will the employees be replaced by robots or will they only get more assistance? It could also be possible that their normal tasks shift to new ones, the focus might shift from serving the food to customer interaction for example. There is currently a shortage of human employees in the horeca so these robots might also form a solution to that. [2]. As mentioned before, the robots might also get developed enough so they can be the solution to any epidemic or pandemic equivalent of COVID-19.

- Enterprise

Right now the robots are mainly used as a marketing trick to attract guests. They are not very profitable yet. But maybe in the future when they are further developed they might become more profitable and they can help boosting the efficiency of the horeca.

The needs and requirements of the stakeholder will be discussed later in the report.

State-of-the-art

For this research, we were looking for different types of robots that already exist and work in the horeca. When looking for robots we discovered that they could be categorized into roughly two types. Firstly the server tray robots, these robots have a purely functional form, the interaction with humans demands a lot of action from the user. The second type looks more humanoid, these robots interact more with the users and look and act more like humans. We did some research on different types of robots and the way they work. They are stated below.

Server tray robots

LG CLOi ServeBot

Type/purpose [3]

- Serves drinks and small snacks

- Lika a moving vending machine

Pros

- Has a large storage so it does not need to be refilled or pickup orders often

- Quite robust

- Relatively large wheelbase compared to the height

Cons

- Can only be used for big open space e.g. casinos, events, convention

- Can only carry a limited selection of products

- A large amount of customer effort required

- Very limited personal interaction with the customer

Coronavirus application - Limits interaction between cashiers and customers. But bigger conventions are probably not realistic during a pandemic. Thus partly defeating the advantage of using this type of serving robot as a precautionary measure to limit the exposure of staff and customers.

Application after pandemic ends - Convenient for some customers that happen to be thirsty or a bit hungry when they spot the bot moving about. Basically, a moving vending machine and might for this reason be economically viable.

LG CLOi ServBot

- Moving serving tray

- Brings orders from the kitchen to customers at the table

Pros

- Limit exposure of staff to customers

- Customers can sit at the table and not wait in line with other customers

- Some personal interaction with customer possible through the screen/speakers

- Food is ready to be consumed right away

Cons

- Needs flat unobstructed space to operate

- Some customer effort required (e.g. standing up and taking food from tray)

- Food is exposed while driving around, it will lose heat

- Potentially limiting the number of orders this type of robot can deliver in a single go without food getting cold

- Food on plates limits the acceleration/deceleration potential before food might be displaced

Coronavirus application - Useful to limit customer and staff interaction at a fastfood/large open restaurants. If combined with an app customers could go straight to the table to limit their exposure to other people.

Application after pandemic ends - Reduces the amount of staff needed at a big-open/fastfood restaurant. Therefore potentially economically viable.

Starship

Type/purpose [6]

- Food delivery robot

- Brings orders from a kitchen to customers at a specific location. (Table/home/park etc.)

Pros

- Limit exposure of staff to customers

- Customers can sit at table and not wait in line with other customers

- Or stay at home/in the park etc

- The food is insulated which means the food stays warm for longer

- Allowing for larger travel distances

- Robust design so it does not tip over easily

- Low center of mass

- Large wheelbase compared to the height

- High speed potential

Cons

- Needs flat unobstructed space to operate

- Some customer effort required like standing up and taking food from inventory

- The food in bag is not ready to eat right away

- Low to the ground so it is hard to spot

- If operating outside, the environment is far less predictable which may cause problems

- Potentially inconvenient to other users of the infrastructure

Coronavirus application - Useful to limit customer and staff interaction at a fast-food company or a large open restaurant. If combined with an app customers could go straight to the table to limit their exposure to other people. They could even stay at home which would be the ideal during a pandemic.

Application after pandemic ends - Reduces the amount of staff needed at a big restaurants. Therefore potentially economically viable. Could potentially replace the current food delivery system.

Bear

The bear robot belongs to the category of server tray robots. There are two different types, Servi and Mini-Servi. They both have 3 levels with plates which can carry different things like drinks and food. The Servi is meant for restaurants and the Mini-Servi is a better fit in bars and for serving drinks. They are easy to install and multiple robots can be used at once. The robot can be controlled with the attached touchscreen or with an external tablet. There is also the option to look at the analytics to monitor and improve the robot. Both robots weigh 33 kg and can carry 30 kg and their battery works for 8 up to 12 hours. The only big difference between them are the dimensions. [7]

Jamie

This robot was being used at DADAWAN as a welcomer and would measure the temperature of the customers. It could be a solution for less human interaction between staff and customers in times of a pandemic while also being able to measure the customers' temperature. Because of the look that is almost humanoid people will feel a warm welcome. But taking the temperature could take some time and wouldn't work if more than one person stood in his field of vision. A lot of times the robot was also unable to accurately measure someone's temperature.[8]

Dexter

This robot was being used at DADAWAN, mainly for taking away the dirty dishes. It had a more functional than aesthetic look. [9]

Pros

- High efficiency, it can carry multiple dishes at the same time

Cons

- Low human likeness which might cause a less cozy environment

Humanoid robots

Amy waitress

This robot was being used at DADAWAN, his main goal there was assisting the waiter with bringing the orders to the table. But Amy has more abilities, she can be used as a shopping guide, a consultant and she can work at the reception. [10]

Pros

- It has a humanoid look, which makes it more appealing for the customer

- Can carry more than humans

- Has speech interact with costumers

Cons

- Amy only has 2 trays to carry food around, these trays are also a bit unstable making the spilling of food more probable.

- She also does not have an external way of taking orders, everything is done from the screen on her chest.

- Very stiff motions [11]

OriHime-D

Avatar robots with a length of 1.2 meters tall, is developed by ORI Research Institute. “OriHime-D” can be controlled remotely to carry out tasks that involve physical labor, such as guiding customers to destinations and carrying things. Those robots are used at NTT and DAWN. [12]

PROS: Gives the chance to people with (physical) disabilities to do jobs like that of a tourist guide or a receptionist, which will otherwise have been hard due to their disability. This robot can be controlled remotely to move around and it’s operator can also talk through it.

CONS: It does not have a lot of space for carrying goods and products.

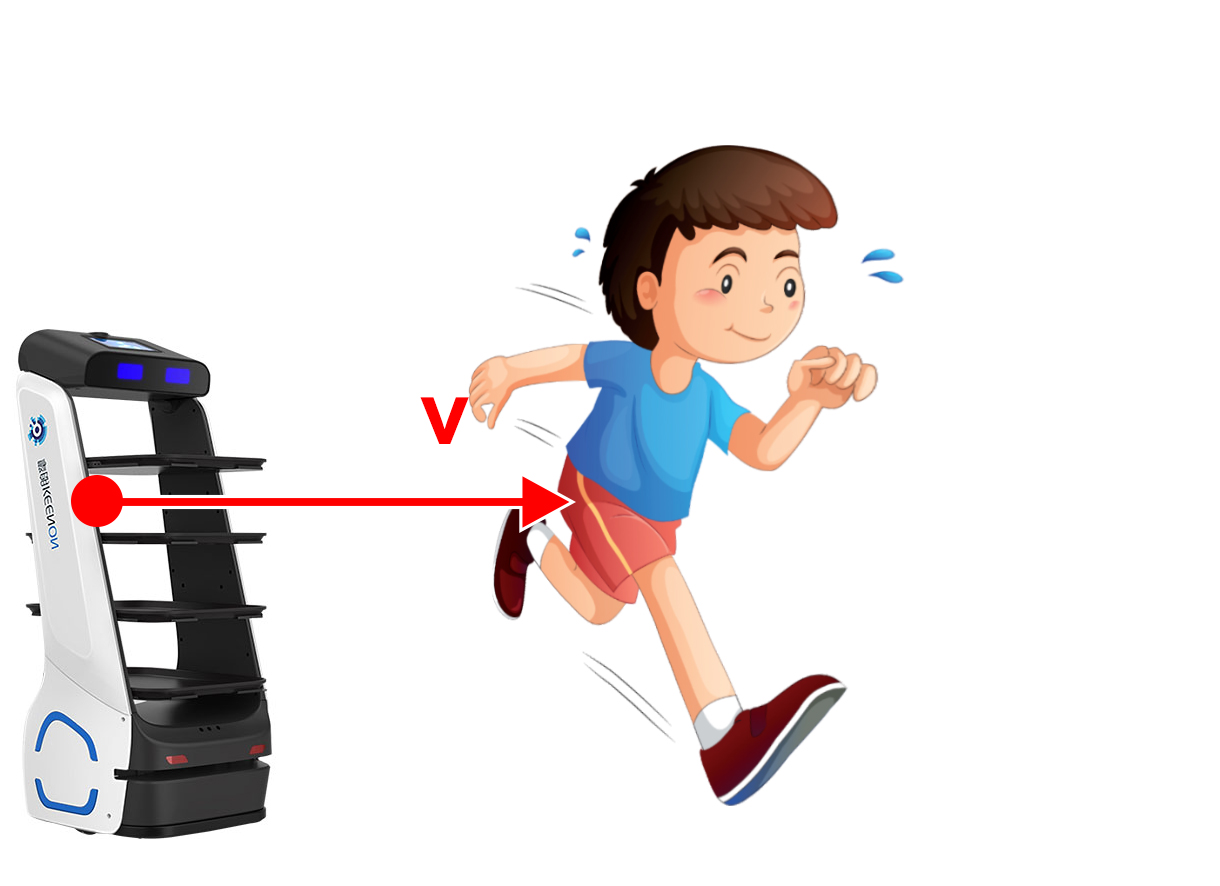

Dadawan

One restaurant in the Netherlands seems to stand out the most when it comes to applying robots in their restaurant. This restaurant is named Dadawan and they already tested out three different robots. One for welcoming guests and two different types of robots for serving. They also did some experiments with the robots to see if they could make their restaurant coronaproof. [13]

Guest are welcomed by a little robot named Jamie that will take their temperature, if their temperature is normal the people can follow the robots to their seats. They have to order their food online via an app and a bigger robot named Amy will then bring the trays with food to their table. Guests have to take the plates from the tray themselves. Not all the work is done by the robots, they mostly do the logistic work. There are still employees walking around, they can now focus on other work and help the guest with different requests. The last robot is Akatar (also named Dexter), this robot helps with cleaning everything up. The employees have to place the trays on the robot and the robot will then take everything to the kitchen. [14]

Both the people from Dadawan and their guests keep emphasizing that the robots really enhance the experience of eating out. The owner of the restaurant, Danny Deng, keeps emphasizing that the robots are not a replacement of his employees but are there to help them. The robots also help to increase customer friendliness according to him because his normal employees now have more time for the guests. Furthermore, they also help with saving time.

The robots come with a standard software package but Danny Deng still has some programmers working for him to optimize the program and to implement the floor plan of the restaurant into the robot. Danny Deng also states he has bigger plans and wants to open a restaurant that is fully operated by robots. [15]

Approach, milestones and deliverables

Our approach in helping to improve these robots is in the first place to extensively talk with an important stakeholder we found; the restaurant Dadawan. Unfortunately due to corona we are not able to visit their restaurant but they still offered their time to us for an interview. With the help of this interview we want to get to know what the different aspects of the robots are that still needs to be improved. After we have analyzed all the problems we will pick one and try to come up with solutions and suggestions. Our research could therefore be in the form of an experiment and/or a brainstorm to come up with new designs or little improvements to the robot or its environment. Our deliverable will be the solutions and suggestions we come up with during our research. We will also give more recommendations as to what the robots should be able to do in the future to make them work even better.

Stakeholder: Dadawan

To get to know more about the specific problems that come with implementing robots into a restaurant we held an interview with an important stakeholder. This stakeholder is Paul Seijben, he works for the restaurant Dadawan. Dadawan was one of the first restaurants that actively used robots in their restaurants, they are now one of the frontrunners in this field in the Netherlands. Dadawan imports the robots from a factory in China so they dont know all the technical details about the robots but they have worked and experimented with them for some time now.

Our goal for this interview was to discover if there were any big problems that they encountered while using these robots and if we could maybe come up with solutions or suggestions for them. The conducted interview is written out down below, the answers are not quotes but globally what he told us. The points that we got out of it will be discussed in the next section.

Interview with manager

Q: What made you decide to work with robots? What was your motive?

A: Danny (the owner) traveled to China a lot and discovered these robots. In China, way more restaurants use these robots already. He contacted the factory and imported a few robots straight away. The main reason why we wanted to implement these robots in the restaurants was to help our employees, they have to work with very heavy plates so using these robots could make carrying them easier.

Q: Does the robot meet your expectations?

A: It was harder than we initially thought to implement these robots in our restaurant. The suppliers always tell you the best points only of course. Especially the mapping and programming. We even hired a freelancer to help us with programming the robot. The robot Jamy also didn’t work for us, the whole process of bringing people to their tables and taking their temperature took way too long for when it is busy. Taking the temperature also didn’t work once there were people standing behind them.

Q: You now have two robots in use, Amy and Dexter, what are your experiences with them?

A: Amy looks more human and is more interesting to our guests. We see that this especially works well for marketing and on things like social media. Amy is less functional than Dexter but Dexter gets less attention from the guests. The efficiency could still improve for both of them, together with their navigation. They are still quite slow and walk around very rigidly, we would like to see them more flexible in the future. The biggest problem was that they are unable to communicate, so to avoid collisions we could only send out one robot at a time.

Q: How do you set up the robot? Is it all ready when it arrives?

A: We expected it to be easier to set up the robot but it turns out that the mapping of the restaurant is quite hard still and we still had to program a lot of things ourselves. It would also be easier to implement them into a restaurant that was designed for robots, we now had some extra challenges because of this. Asking the supplier about our problems was also quite hard because of the language barrier.

Q: What would you like to see improved about the robots, what are the points of improvement? A: It would be nice to see them improve on navigation as I said before. We also contacted the factory because we would like to have the option to control the robots from something like an apple watch. Right now our servers have to walk to the robot or the kitchen to give it its orders. It would be nice if we could do this without having to walk back every time. Because we have these heavy plates it would be great if these robots would follow us with the plates. This way we don’t have to walk back to the kitchen 4 times if we have an order for 8 people, we could just take all these plates to the table at once. It would also be nice if the implementation of the rootings would be made easier, right now we had to hire a programmer to do this for us.

Q: What is the main point of added value these robots bring you?

A: Amy works well for marketing especially. Right now they only cost us money and our employees don’t really trust them yet and are hesitant to work with them. But we want to keep working with them and keep improving their efficiency.

Q: Would you see options to use these robots during the pandemic?

A: we did some experiments with them and they worked quite well, the only downside was that our hospitality goes down if guests’ only interaction is with robots. We think people would agree to this during the pandemic but it has no further future after that for us.

Q: How did your employees find working with these robots?

A: At first they were really hesitant. Most horeca employees aren’t really technical, they just want to work with people. This bumped a bit at the beginning but we think that once our employees trust the robot more than the collaboration will improve a lot. Our employees should be able to trust the robot to do its tasks and do them well.

Q: What is the reaction of the guests when they see your robots?

A: They mostly find it interesting to see how it works. Right now we don’t see these robots as replacements for our employees they just add something interesting to the restaurant. The reactions online can sometimes be negative, people say this is absurd and that our hospitality suffers from these robots.

Q: What is your ultimate goal with these robots?

A: I am a bit more skeptical than Danny. We just want to experiment with this product, but we also depend on the technical world. As long as these robots don’t really work like we would like them to it is hard for us to implement them into our restaurant of course. We can only keep trying and investing in them and hope for the best. in the end, we hope to have 3 robots per restaurant to help our employees. This would also require more trust in these robots from our employees.

Interview with programmer

Our communications with one of the engineers (Matthias) hired by Dadawan to help install and program the robots consisted of a couple emails and a phone call. The main take-away from these conversations were that a lot of the problems that Amy faced would be solved by the new robot that they are currently in the process of implementing, which is the Keenon T5.

Problems solved by the T5

- Amy sometimes tumbled glassware with sudden jagged movements. Matthias explained that this often occured when the robot tried to avoid an apparent obstacle in the path it was trying to follow. For some unknown reason the error between where the robot thought it should be and actually was was a couple centimeters and thus when trying to correct this error the movement was sudden and jagged causing glassware to fall. The Keenon T5 does not navigate by following lines but by triangulation with markers on the ceiling. So this should no longer be a problem.

- The Amy type robot navigates by following lines and cannot communicate with each other. So to avoid getting the robots stuck together or causing incidents only one robot could be out in the restaurant serving at a time. This again will be solved by the navigation technique used by the new robots. They also stream their location via wi-fi and can communicate with each other in this way.

- Even very tiny unevenness in the surface like small bumps or holes were a problem for Amy. Caused by a rather poor chassis and hard plastic wheels also not providing any dampening. This again could even cause glassware to tumble. These problems will also be solved since the Keenon T5 has a far better chassis with larger and softer wheels providing enough dampening for decent roll-over of small inconsistencies in the surface.

- DADAWAN wants to operate the new robots at 0.8 m/s. Which is still well below a decent walking speed, but still twice as fast as Amy was.

Due to all these problems in practise Amy actually never carried filled glassware. It was just too unreliable. If the robot did carry drinks perhaps different serving strategies could become an option. Were the person taking the orders and serving the drinks and food never actually has to leave the table area. This will give the servers more time to interact with the guests and in general be more available to the guests.

The only time the Keenon T5 should get into trouble with glassware is when it is forced to make an emergency stop. The robot is equipped with Lidar and therefore should have no trouble with obstacles that are visible from it’s point of view directly in its path. The obstacles are of course often humans who will (if necessary be obliged to) step out of the way most of the time. The robot will only actively slow down when the obstacle comes within 1.5 seconds of impact. Since the maximum speed is not very high the deceleration will be pretty low, this deceleration should not cause incidents with the glassware. But, Lidar cannot look around corners or other obstacles like tables or chairs. These places are then also the most likely for accidents. While not providing an exact figure on the braking force Matthias assured us that the robot should at any speed and load-capacity be able to make an emergency stop within 5 centimeters.

Right now the only attempts of the robot to transport glassware have been at very slow speeds, for safety reasons of course. At maximum speed an emergency stop in 5 centimeters will likely result in tumbling glassware, but, perhaps if subjected to a different maximum speed this would not happen. It also seems reasonable that the type of glassware will determine the maximum speed. Since in general a glass with low center of gravity and a wide base like for instance some whiskey glasses will be far harder to tip over than a glass with a high center of gravity and relatively small base like the typical wine glass.

We will attempt to find the maximum speed the robot can travel at depending on the type of glassware it is carrying experimentally. This will allow the robots to be more universally applied and not only a helper that is almost solely used to carry heavy stone bowls.

The results of this experiment can also be used to model the impact this approach will have on the operation of the restaurant. The main metric that is used to determine the robots efficiency will be the peak servings per hour. This will be the servings per hour when the restaurant is completely packed and thus also most prone to accidents.

Analyzation of found problems

While looking at the state of the art for robots one might be fascinated from the progress done the past years and at the possibilities offered to users, society and enterprise. All three have potential to benefit from this new technology. But as we have seen, not everything works perfectly yet. In the section below we are going to go through some issues that became clear from these interviews. It will give a short description of the four main problems that emerged from the interview.

From the interview it was clear that the expectations of dadawan on the navigation and mapping of the robot were not met. The biggest problems were the mapping of the robot, this turned out to be too hard for them to do alone. And even the professional programmer faced some problems. The robot also has its limitations of where it can go and how much space it needs to move. This means that if the current layout of the restaurant is not optimal for the robot either the layout or the robot should change to solve this. The mapping of the robot is quite hard and labour intensive but once the robot knows its path it does its work well and arrives at his destination. Possible solutions would be to change the navigation system. Instead of using a programmed model of the environment they could use a system with lasers, QR codes on the ceiling or lines on the floor. This would work best if the layout of the restaurant took the limitations of the robot in account to make the paths more efficient. So for example place the kitchen in the middle to reduce pathlength and make the paths wider so the robot can fit. Also make sure the robot can reach the table, booths and round tables wouldn't work well for example.

Interaction with the guests

Dadawan had no clear complaints about the interaction with the guests, the robots work well and Amy seems like a friendly robot to their guests. Because it is all new to them, the guests find the robots quite exciting so for now the robots work well for marketing especially. The decrease of hospitality is only caused by the fact that it is a machine and not a human that serves the guests, it is not caused by any specific behaviour of Amy. One exception to this is corona, people seem to find the decrease of hospitality less of a problem if that means they can go to restaurants again. The robots seemed to be a solution to open the restaurant without much person to person interaction. Dadawan did some tests to try and make their restaurant safe to open but the robots didn't work well enough yet. Jamy was too slow and taking the temperature didn't always work very smoothly. The robots also were not fast enough yet to run the restaurant on their own. Solutions to this problem would be to drastically improve the Jamy robot, especially the speed of taking the temperature and the displacement speed

Interaction with the employees

The employees had some trouble adjusting to the robots. They are not used to this kind of technology and would also rather not work with it. This is mostly caused by a lack of trust in the robot, they would rather do the work themselves and know for sure it gets done well. They don't see a reason to use robots for this. To solve this problem firstly the attitude of the employees towards the robots should change. They have to learn more about them and work more with them. See how well they do their job and also realise they will only keep improving. The robots definitely have some points of improvement, if they start to work better over time the trust of the employees will only grow. They just have to realise that the robot is able to do its work well. Some research could be done after how people react to robots and how we can make them trust the robots or at least willing to work with them.

Improve their efficiency

The robots are meant as a support for the employees. Dadawan would preferably see that the robots would go faster so they go more rounds per night but also so they can follow their employees to the table. This would happen if the servers have to carry too much at once (one stone bowl plate is already around 2 kg) so the robot can carry the heavy things. Dadawan would also like to be able to give the robots commands from different points instead of only on the robot itself. The robots should reduce the amount of times the servers should walk to the kitchen but right now the results are not as high as they hoped for. Dadawan would like to see the servings per minute the robot does increase so that their added value is more than just marketing. Solutions to this problem would be to solve the problem of lack of communication between the robots so more than one at the time can be out in the restaurant. The other options are changing the layout of the restaurant or improving the design and program of the robot itself. Make them go faster for example, while still making sure they can make their emergency stops. Designing a system that would give the robot its tasks in a more efficient way so it doesn't have to go back to the kitchen every time it finishes a task could also work.

The experiment

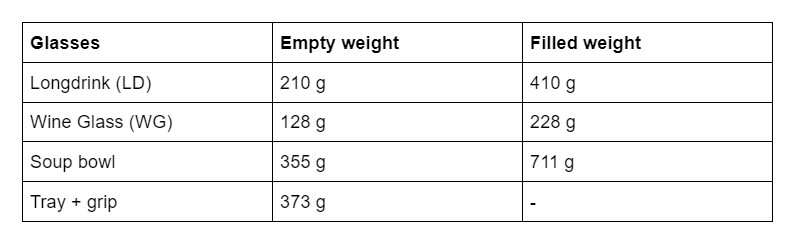

After we have conducted this experiment we will also suggest more solutions to improve the maximum speed of the robot. The maximum speed that is allowed is the speed for which the glassware on the robots tray will not tumble during an emergency stop. When at this maximum speed the emergency stop has to be made in exactly 5 cm. One could argue that if stopping in 3-4 cm is possible, this would be safer. But considering that this could come with glass raining down from above it will likely be safer to just always stop at 5 cm. Different kinds of glassware have a difference in stability and fall down at different decelerations. The experiment is done with the two types of glassware that are likely the most vulnerable to tumbling when decelerating. Namely a long drink glass and a standard red wine glass. Glasses can be transported full or empty which will also impact the maximum speed. We will later get back to why we chose to separate the tableware into different categories.

The problem

Let’s have a look at how we can simulate the acceleration needed to stop the robot on time.

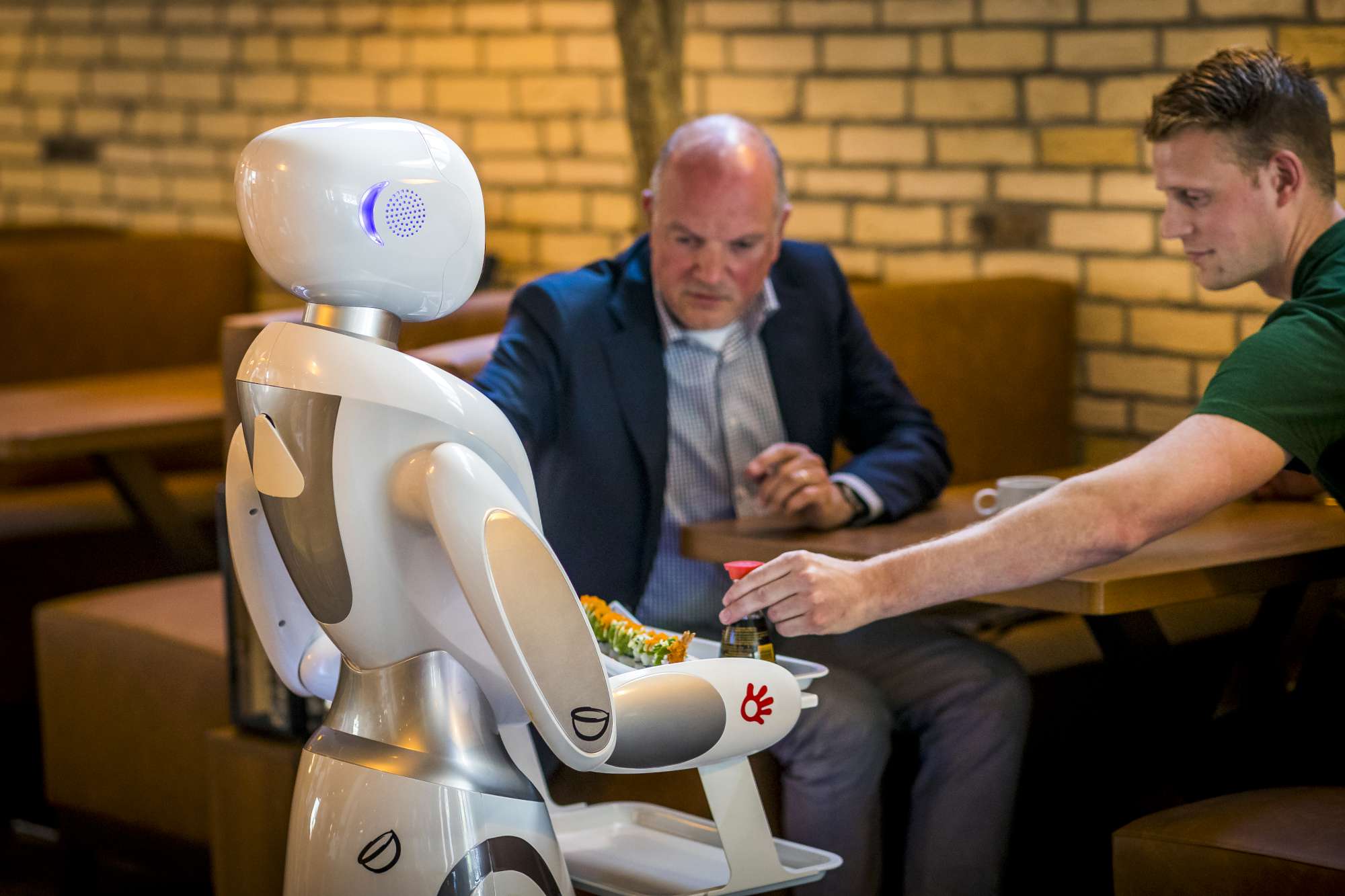

Assume we have a robot moving with speed v inside our restaurant assisting our waiters in carrying the food and drinks. Suddenly a kid unexpectedly jumps in front of the robot; immediately the robot senses that movement through the sensors now it needs to decelerate in time.

Unfortunately is fully loaded, breaking with its maximum force will cause the food and drinks to spill, this will cause not only the spilling of food but also a lot of mess since the robot itself and the restaurant floors will need to be cleaned. As it has become clear this is something that we would like to avoid, so people can receive their orders on time and waiters can continue with serving the customers instead of cleaning.

To achieve this we want to test which accelerations different dishes allow us to break with. Knowing the acceleration and the range our sensors read at we can decide the maximum speeds the robots should use for different drinks and food. This way it will not be overprotective slow in cases the dishes can take a harsher stop.

Theory

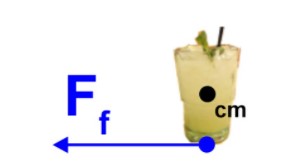

Our focus lays on what is happening to the trays and more specifically on them; Let’s have a look! Since the trays are attached to the robot they will uniformly move with the same speed v and deceleration -a.

In that way we can simplify the problem and only look at the tray. When moving at a constant speed or standing still the velocity between the glasses and the tray is 0. When the brakes are activated the glasses feels the force F. The glasses, due to inertia will try to resist the change of velocity. This force applies a torque on the glass causing it to rotate and tip over.

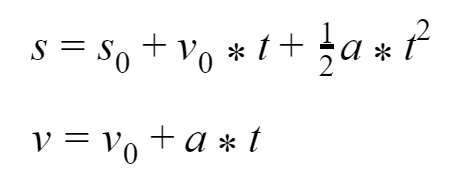

We now will have a look how we can see what speeds should be allowed for different types of dishes. In our experiments we took videos from a panoramic view, in those videos it is clear to see at what time our tray has made what displacement.

The experiment

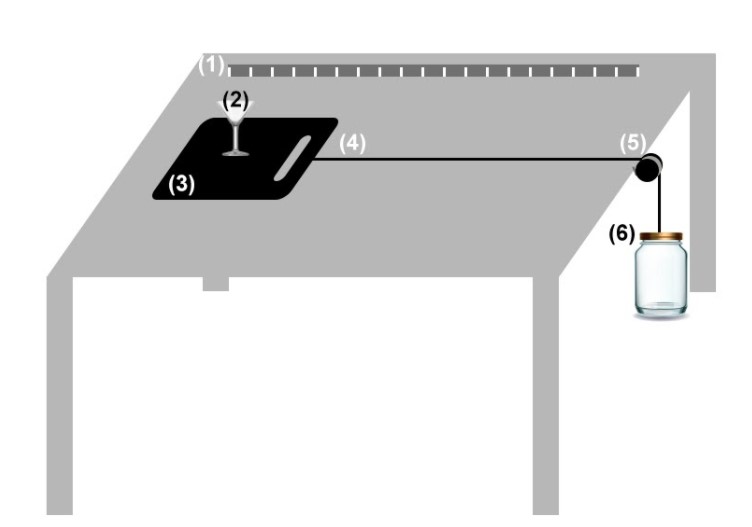

For the experiment the setup shown in figure 15 was used. The dishes would be placed on the surface that represented the tray. This surface was of a rubber-like compound that has a high friction with the glasses. The weight hanging on the end was carefully measured and hung about 1.10 meters above the ground. The ‘tray’ then had to be released and would move across the table, this motion was filmed from above. With the help of the ruler and the time stamp on the videos the average speed of the displacement could be calculated. There were multiple trials for each dish and every dish would be measured full and empty. The weight hanging on the end changed after a few trials to see if the dish would fall down if the acceleration would increase. This was done in little steps until the point where the dish would fall down was found. The weights of the dishes can be seen in table ##. This experiment measures the acceleration from a standstill and not deceleration from a constant velocity. If the deceleration and acceleration are the same the forces that tip the glass over will be the same magnitude but in opposite directions. Thus this experiment will simulate a robot braking with a constant deceleration. Given that the robot should stop in 5 cm. A maximum speed can be calculated that the robot can travel and still keep the glasses upright in the event of an emergency stop.

The movement is governed by the following equations.

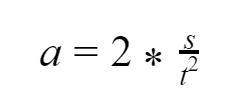

Given that the starting distance s0 and initial velocity v0 are both 0. The acceleration can be calculated with

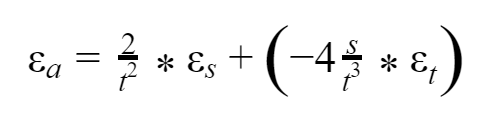

The uncertainty or error in the acceleration is therefore given by

The uncertainty in time follows from the experimental results and the uncertainty in distance is estimated by looking at the approximate distance traveled between two frames at the moment the cutting board crossed the 50 cm line.

The acceleration that we have found experimentally will be the same acceleration and deceleration that the robot should use so it can carry every menu item available.

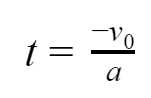

The most crucial part is the emergency stop. Given that the final velocity is 0 equation 2 can be used and solved for the stopping time.

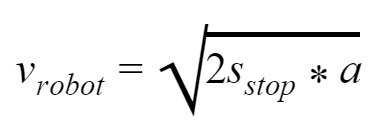

Plugging this into equation 1 gives the equation for the velocity the robot can travel at and stop at a specified distance s_stop given deceleration of a

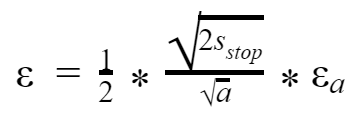

The error in this will be given by

From our conversations with Dadawan the desired stopping distance should never exceed s_stop=5 cm. Using this the velocity of the robot is calculated.

Results

For the actual raw data gathered from the experiment look in the appendix.

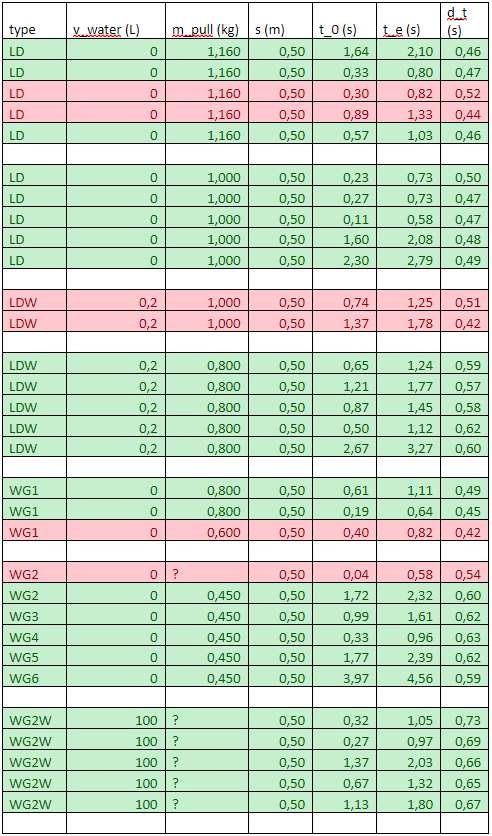

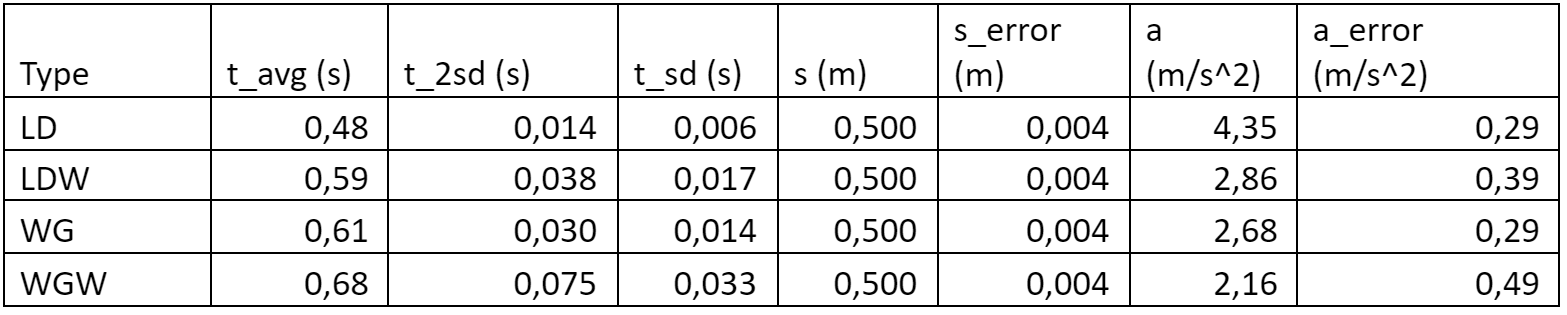

In the table below are the results from the experiment. With LD and WG standing for Long drink (glass) and wine glass and the optional subsequent W for containing water. The second column denotes the average time it took for the tray to travel 50 cm, column 3 and 4 2 times and single time the standard deviation. The error in the time used to calculate the other variables was taken to be 2 times the standard deviation. s(m) denotes the traveled distance. s_error the error in distance one frame of the camera would be at this distance. Here the results from the fastest LD measurement were taken as the error for all the measurements. This finally gives the average acceleration over the movement and its corresponding error.

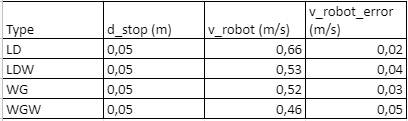

Now that the accelerations are found that the different types of glassware can withstand. The maximum speed that the robot should operate at and still stop within 5 cm can be determined. This is calculated rewriting equation 2 to find the time it takes to make an emergency stop. Which is given by equation 5. Plugging this into equation one and solving for the velocity gives equation 6. The error in this calculation is given by equation 7. The results of this calculation is given in the figure below. Where d_stop is the stopping distance, v_robot the maximum velocity and v_robot_error the error in this velocity.

Conclusion/discussion

The results of this experiment confirm earlier assumptions about the decelerations different glass types can endure without tipping. Also not surprising is the fact that when the glasses contain water the will tip over easier. This might not be the case with every shape of glass, but in the cases of long drinks and wine glasses adding water will increase the height of the center of gravity. Making the glass more unstable. Also although not measurable in this way, the inertia and fluid motion inside the glass could also contribute to this. All of the maximum robot velocities are lower than the velocity DADAWAN wants to operate at. Which is 0.8 m/s, significantly higher than for instance the maximum velocity when carrying a filled long drink at 0.53 m/s.

If one wants to implement these speed limits. Some other things also have to be considered. For instance, the robot will most likely in most cases not have a constant deceleration when applying the brakes. If the braking force is too high the wheels will also get locked and the robot will go from rolling to sliding, which is definitely not a constant deceleration from start to finish. Locking the wheels however as in a car will increase the stopping distance, which is never desirable. Even when using some form of ABS the braking will definitely not be constant if the ABS has to kick in. Thus the brakes have to be applied with some more care. Like a human would when driving a bicycle. At first when still going fast the brakes can be applied with force, but when you are slower you release the brakes slightly in order to not lock up the wheels. When applying this to the robot, some peak braking force has to be determined for a given load and velocity after gradually releasing (never completely of course) to reduce the speed. This way a constant deceleration can be achieved. To always achieve a desired deceleration, as is necessary for the glassware to stay upright the robot will have to know its own weight and velocity at any given time. In most cases the carrying load will not be significant, but when it is perhaps it can be estimated by the acceleration a certain motor input will provide.

This experiment also has some other shortcomings. Unfortunately we were not able to acquire the exact glassware that DADAWAN uses in its service. Different shapes and weight of the glasses will impact the results. Also while we measured the contents of the glasses to an exact amount, the glasses in the restaurant will likely be filled by feel. In reality the surface of the trays under braking will not stay completely horizontal. Although due to the solid chassis this effect could be minimal. The release mechanism was just a finger. Which will release slower when under load. Although perhaps not the biggest impact, this would mean that the acceleration was actually higher since the frame that the board first moved was counted as the first frame. While perhaps the board was not released completely yet.

Modeling Results

As stated before the average round trip time can be taken as the determining factor in the efficiency of the robot. This round trip time does not take into account the amount of servings the robot will have to do, we assume that this will average out over time though. A lot of factors have to be estimated when considering the average round trip time. We came up with the following model

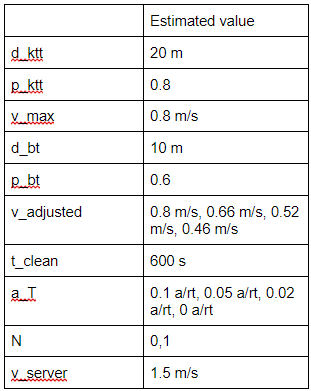

Where t_avg is the average round trip time, d_ktt the distance from the kitchen to the first table, P_ktt*v_max will give the average speed from the kitchen to the tables. Where p_ktt is sort of the percentage and v_max the maximum speed. This term takes into account all the acceleration and potential slowing down that the robot will have to do during a trip. d_bt gives the average distance between tables, here accidents are most likely. Therefore the strategy even when using an adjusted speed is to ONLY use this adjusted speed in the area where accidents are most likely. Here the spaces are also less open and thus detecting potential obstacles becomes harder. Thus P_bt*v_adjusted will give the average speed that is achieved during the transit between the tables. Here v_adjusted will give the adjusted maximum speed. t_clean gives the average clean time when an accident occurs and a_T the average amount of accidents per round trip. In the case where no adjusted speed is used, as the server will have to pick up drinks, this time is added to the total time of a round trip. Where v_server is the average speed of the server and N either 0 or 1 if a server has to be used to pick up drinks or not.

The idea is when an adjusted speed is used. No accident will occur. In reality the round trip time might be even faster, since the p_bt is fixed here while when you go slower this term might get higher.

It shows that even when using the slowest adjusted maximum speed. The average trip time is still very competitive with the strategy that is currently used. Which requires a server to pick up and deliver drinks themselves. In this model some delays that will impact all the strategies are not added to the total time. Like actually serving the food and drinks from the trays to the table or filling up the serving tray of the robot and server with food and drinks. A lot of the time the robot will also have to wait until an order is ready before it can go out.

Further recommendations

When the robot needs to make an emergency stop, the plates and glasses will experience a sudden force and may tilt or even fall down. In the experiment above we discussed what the maximum deceleration of this emergency stop should be where the tableware would still stand up and nothing would move too much or break.

In this experiment, the types of tableware varied. They were either empty or filled with water or food because the robot has to bring both filled glasses and plates to the table and take the empty ones back to the kitchen. The maximum decelerations where no tableware would fall or break were measured for each situation.

But apart from alternating the type of glassware, there are more ways to increase the maximum deceleration. The easiest way is to change the glassware to heavy glasses and plates with a low centre of gravity. Glasses like whiskey glasses for example would work well. This would also mean the restaurants are limited in their choice of glassware and even if the glasses won't tilt, the drinks inside might still spill out at high speeds. That is why some recommendations on how to improve the stability of the glassware on the trays will be given below. These suggestions are not tested as done in the experiment above but still seem quite promising in solving the problem. They are meant as an add on to the solutions given by the experiment. The first designs and ideas will be given below.

Suggestions to the serving tray

Top heavy support

Top heavy glasses are the hardest to transport as they have a higher chance of falling down. Plates on the other hand are way easier to transport because they dont have the same high moment of inertia as wine glasses. Examples of top heavy glasses are cocktail and wine glasses. To make sure they keep standing a different system may be designed to attach to the plates. This system supports the glasses on their stem. * tekening toevoegen * The system should be easily attachable to the backside of the plates and should be easy to remove.

Extra grip

The serving tray could also be tweaked to make it work more efficiently. Current trays used by the servers are already working well, especially with the grip on the top and bottom of the tray. But the trays that Amy uses are quite frictionless which means that the plates and glasses tend to slide more easily. Especially when she makes sudden moves that include acceleration, deceleration and making turns. It would be a small effort to change the current trays to trays that have more grip or even add more grip to the current trays. During the experiment above for example we chose to make the friction between the tableware and the tray quite high which meant it should be harder for the tableware to fall.

Cup holder

If the robot should really go fast and also transport mostly drinks then this solution could also be used. The tray could get certain molds, especially made to hold glasses. The system would work something like a cup holder. Some robots already exist that have this feature (see in state of the art). The only downside to this is that this tray can now only transport glasses. To solve this problem, the glasses tray and normal tray should have a system that allows them to be easily exchanged. Or the tray with molds should be easy to click on and off the normal tray. The second problem is that the glasses should always be able to fit into the molds. If the restaurant has multiple sizes of glasses this could become a problem. The tray could either have different sizes of molds, but this could make it less efficient. Or the restaurant should get glasses that are almost the same size so they all fit inside the molds.

Gyrometer

This solution is a bit more complicated. The robot should be changed for this to work, but it could work if it would be integrated in the next generation of server robots. The idea is to add an extra Gyroscope and accelerometer sensor to the robot. The gyroscoop can measure and maintain the orientation and angular velocity of an object. And the accelerometer tells us the acceleration of the robot and makes the motion sensing more accurate. They can also measure the tilt of an object. Most robots already use vibration gyros for balance control, they are also used for motion sensing. Vibration gyros are a type of gyro sensor that uses a double T-structure and a crystal element to sense the motions. A picture of the sensor is shown below. The goal of integrating a gyrometer in the robot is that the robot can now be programmed to tilt the tray when it is accelerating and decelerating, something servers already do automatically. If the robot knows how far it should tilt the tray for certain speeds and accelerations, the glasses will be less likely to fall. The tilt system should be programmed into the robot and the robot should know exactly when and how far to tilt the tray. If this program works well this means the maximum acceleration and deceleration increase.

Example of strategies of communication between kitchen, waiters and serving robots

At this point it would be really useful to get back to one of the main goals of this project; Improving the teamwork between the serving robots and staff inside and outside the kitchen and increasing the efficiency. Here I would like to refer back to the role of the robot in the restaurant (according to our stakeholders): the robot will be there to mainly assist the waiter by taking over some load of bringing the meals and drinks to the tables. This will give the waiter more time to interact with the customers and make sure they are having a plausible visit to the restaurant.

As also mentioned by the stakeholder, we came in contact with one of the biggest drawbacks, of the robots they had currently been using, is that the robots did not have a way to communicate with the waiters and the kitchen. This made it harder to work with, so we decided to propose a strategy on how the future generation could work better as a team with the rest of the restaurant's staff.

The general communication model

Next we are going to discuss strategies and implementations which in our opinion could elevate the efficiency of using a robot as a waiter assistance. The ordering will still be done by human waiters, and the currently used point of sale (POS) will still be used. Through the POS the order reaches the kitchen where it is being prepared. When it is ready the ordering is placed on the robot by staff in the kitchen, They also make a selection from the tables (Figure ##) and then from the modes (Figure ##), depending on the type of load. When it is on it’s way the waiter of that section is notified by a small vibration, and the watch (Figure ##) he/she is wearing lights up, showing the name of the robot, the approximate time of arrival at the table and the table itself. The waiter now has in his mind he has to be at the table in a few seconds.

The modes

The first of the strategies we propose is based on our experiments results, we can use those to adjust the behaviour (velocity / acceleration / deceleration) according to what the load of the robot is. This way the robot will be extra careful when needed and can be faster when the load is more stable. This will boost the efficiency by minimizing accidents and using the optimal speeds to reduce the time needed for the food to reach the table. As you can see in Figure ## this could be a possible setup of the displays, scaling from red to green. The former is linked to more careful (slower movement) while the latter means that the robot can move with higher speeds.

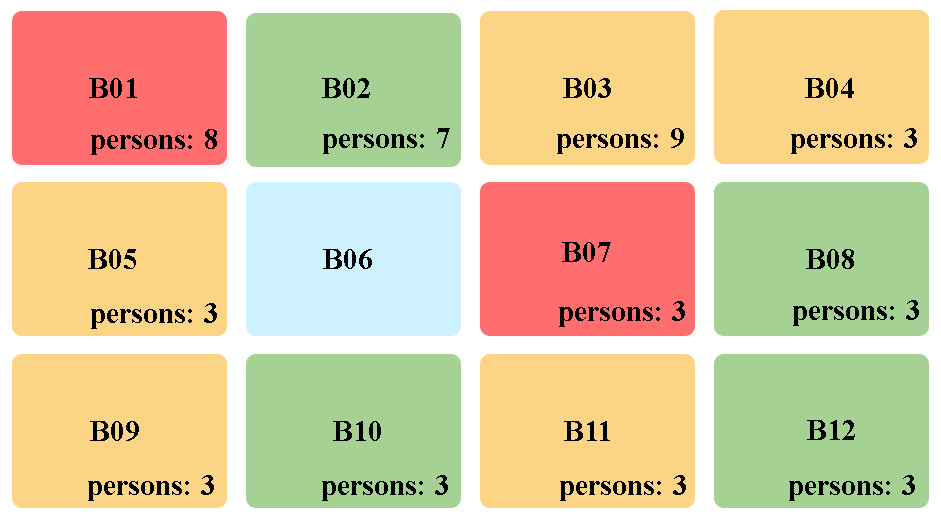

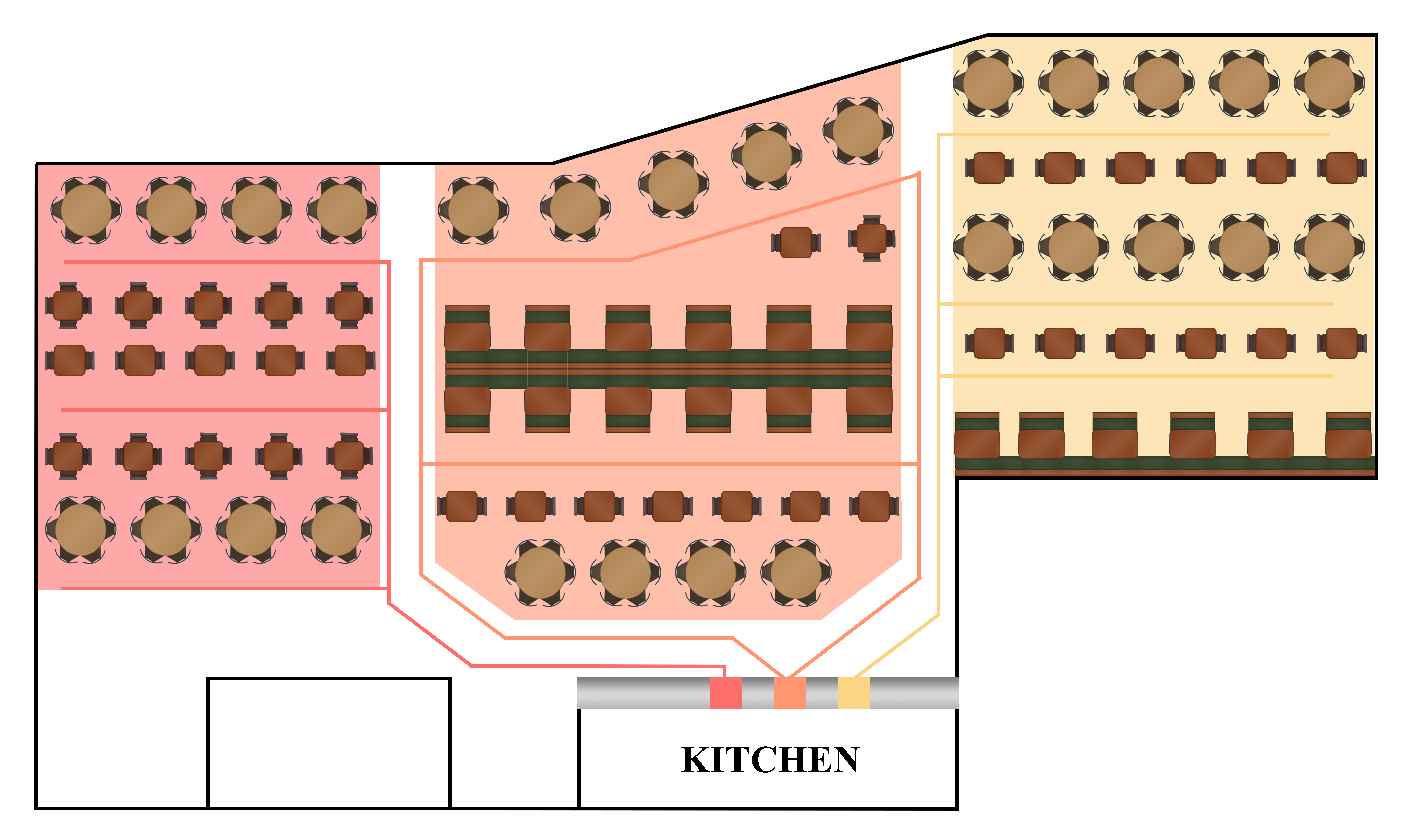

The restaurants tables division in sections

Next, by looking back at our conversation with our stakeholder we discovered another drawback that we thought was causing a lot of trouble, the fact that the robots were coming in each other's paths. One of the areas where this could happen frequently is the kitchen. For this we decided it would be more practical to have a sort of drive in system for the robots. In Figure ## you can see the kitchen of dadawan in Eindhoven, the colored planes show those drive in areas for the robot. This will also give more space to the waiters to move around, because before the robot will have to stay in the walkparth till the waiter has loaded it.

Another way to reduce the discommunication and collision of robots between each other was dividing the restaurant in sections. As it is also represented in Figure ## every robot has a certain area it is serving.

The watch

Last but not least we want to recommend our stakeholder to provide their waiters with the following equipment. The watch, as mentioned earlier, will help in the communication between waiter and robot, so the waiter can know when and where the food is headed to so he can be there on time to do the serving. File:Watch.jpg

Planning

| Week | Planning |

|---|---|

| Week 1 | Come up with different ideas |

| Week 2 | Look up some research papers and try to find a specific topic to focus on |

| Carnival break | Come up with plan for this project |

| Week 3 | Work out the plan and search for stakeholders |

| Week 4 1 - 7 March | Hold interview with stakeholder which will give more answers and show us what the greatest problems are |

| Week 5 8 - 14 March | Work on deliverable, do research and try to find ways to make it possible, look for ways to setup the experiment |

| Week 6 15 - 27 March | Do the experiment |

| Week 7 22 - 28 March | Work out the experiment and work on calculations |

| Week 8 29 March - 4 April | Work on the report, final presentation (video or online) |

Logbook

| student | Task | Time spend |

|---|---|---|

| Together | Had lecture and tutorial, began to look for groups to join | 3 h |

| student | Task | Time spend |

|---|---|---|

| Together | Had a meeting with the group did a brainstorm, thought about interesting topics, had an introductory meeting with our tutor about topics we were interested in | 1.5 h, 0.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros |

State of the art research and furthermore looking into how we could improve the existing robots in the HORECA field. Also had a look at what measures “koninklijk horeca nederland” think are necessary to reopen restaurants during the pandemic. |

2h, 1.5h, 1h |

| Marvin | State of the art research, finding possible improvement that we can do the project about, writing it down for a doc | 3h,1.5h,0.5h |

| Lotte | Introduction research about the state of the art + researching specific topics like navigation systems, look at examples of Horeca robots, write work down in docs | 3h, 2h, 1h |

| Together | Three meetings discussing the research we did about the state of the art, and trying to come up with plans. Write approach, problem statement and objectives together.

Also working on the wiki. |

0.5 h, 2.5 h, 1.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros | Looked up robots and specifications: Amy & DEXTER

Prepared the meeting with the brand manager of DADAWAN, did some research on their current robots, and thought of some questions to ask about the technical aspects. |

1h, 1.5h |

| Marvin | Worked on the questions for the interview | 2.5h |

| Lotte | Work on wiki put everything in a clear order, type out the results of the state of the art research that was found, send email to Dadawan (stakeholder), prepare for meeting with brand manager, did research after Dadawan | 3h, 0,5 h, 0,5 h, 1h |

| Together | Meetings, tutor meeting | 2h, 1h, 0.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros | From the interviews: organise the requirements and sectors that have problems and how they can be improved (possible solutions).

Early version of the one solution. |

1.5h |

| Marvin | Fill in log book, experiments and solutions for speed/efficiency vs dish/drink stability | 0.5h, 3h |

| Lotte | Put planning and logbook in wiki, type out the answers for the interview and put them in the wiki, worked on the preparation of the interview and on the results of it. | 2h, 2h, 1h |

| Together | Meeting with stakeholder + two group meetings, meeting with tutor | 2h, 1h, 1h, 0.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros | Work on what looks to be the solution to improve the efficiency of the robots: Looking at how we can simulate an accident in our own experimental setup. | 2.5h |

| Marvin | Think of an experimental setup, acquire the components and build the experimental setup | 1h,2h,2h |

| Lotte | Search for good glasses to use and get things from the store for the experiment, update approach part in the wiki, think about the further recommendations | 1h, 0.5 h, 1.5 h |

| Together | Meetings (online and offline), prepare for the experiment, mail stakeholder, update the planning, meeting with tutor | 1 h, 0.5 h, 0.5 h, 4 h (per meeting), 0.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros | Work on the Experimental Setup and Example of display | 4 h |

| Marvin | Process the results | 5h |

| Lotte | write out all the suggestions and do research after them, prepare for the experiment, write analyzation of the Dadawan interview with current problems and our suggestions to solve them | 2.5 h, 0.5 h, 2 h |

| Together | Conduct experiment, meeting where we discussed the results, meeting with tutor | 5 h, 1.5 h, 0.5 h |

| student | Task | Time spend |

|---|---|---|

| Isidoros | Organise the docs document. Finish Example of strategies of communication between kitchen and waiters. Make the video for the presentation. | 0.5, 4h, 1h |

| Marvin | Make the slides for presentation, make model | 2h.2h |

| Lotte | make setup of presentation make a layout and make sure all things are included in a logical order, finish writing and researching further suggestions, write parts of the presentation, write experiment method and make sure it all fits with each other and there is no overlap, make sure the document layout is clear, | 2 h, 1 h, 1 h, 2 h, 0.5 h |

| Together | Offline meeting where we analyzed our results and divided the work to do, also divided the presentation | 4 h, |

| student | Task | Time spend |

|---|---|---|

| Isidoros | make a plan of dadawan in Eindhoven and finish the last things of strategies. Move everything from computer and docs to wiki. | 10h, 3h |

| Marvin | finalize the docs and wiki | 6h |

| Lotte | write for the wiki, put everything in the wiki, organize the wiki, images and references | 2h, 2h, 6h, 3h |

| Together | Online meetings (5x, we worked on the final presentation & recorded ourselves giving the presentation we also worked on the report), final presentation, put text in wiki | 2h, 5h, 0.5h, 0.5h, 3h, 1h, 0.5h |

References

- ↑ [1] Hart van Nederland (2021, 5 Ferbuary). Bediening robots restaurant maastricht

- ↑ [2] Janssen, T. (2020, 13 January). einde-groei-horeca-in-zicht-door-personeelstekort-en-nieuwe-regels.

- ↑ [3] Corp, L. (2021, 31 March). FUTURISTIC ROBOTS MAKING LIFE BETTER TODAY .

- ↑ [4] Mu-Hyun, C. (2020 03 Frebuary)LG deploys service robot in Seoul restaurant.

- ↑ [5] (2020 09 July)LG launches self-driving LG CLOi Servbot.

- ↑ [6] (2019 06 Januari). Starship technologies

- ↑ [7] Bear robotics

- ↑ [8] Camp, J.V.D. (2020, 27 May) Robots Jamie en Amy verzorgen de bediening in Maastrichts restaurant

- ↑ [9] (2021, 3 March) Dexter Delivery Robot

- ↑ [10] (2021, 26 Januari) Robot Waiter | The Amy Waitress is the Ideal Marketing Tool

- ↑ [11] (2020, 9 June) Amy Waitress Robot, Robot for Hotels , Hospitality Robot, Waiter Robot

- ↑ [12] Takeuchi, K. (2020) Companion of the 2020 ACM/IEEE International Conference on Human-Robot Interaction

- ↑ [13] (2020, 27 May) Deze robots brengen je eten bij restaurant Dadawan in Maastricht.

- ↑ [14] (2021, 05 February) Robots moeten horeca-bediening gaan ondersteunen in tijden van corona

- ↑ [15] Simon, M. (2021, 10 February) Horeca robotica; robots moeten gastvrijheid Dadawan verhogen

Appendix