PRE2019 3 Group5

Group members

| Name | Student ID | Department |

|---|---|---|

| Ana Maria Risnoveanu | 1230444 | Electrical Engineering |

| Stacey Elshove | 1279998 | Psychology and Technology |

| Petru Radulescu | 1371320 | Psychology and Technology |

| Yiqin Hou | 1281135 | Electrical Engineering |

| Tobias Hilpert | 1281070 | Chemical Engineering |

Problem Statement

Today technology for recycling already exists and is put to use in most first world countries, but at times it can be inefficient because of mistakes made by all of us when throwing the trash, either unwillingly or because of our ignorance. So to mitigate this and help create a better planet for the future generations, we have come up with the idea of a smart bins, that will use a wide array of sensors and cameras to determine whether the waste should go in the glass, plastic or paper bin. This product will be small enough to fit in our homes and, in the future, it could be up scaled to service a full residence, like a block of flats.

Objectives

- Design an affordable smart trash can that fits into our homes.

- Use machine learning and AI to sort the trash into their corresponding compartment.

- Find suitable technologies to achieve this.

USE Aspects

User

The user group we wish to target is households, we would like to improve recycling at the source and make it easier for users. To better understand the users' needs, a survey was carried out. Survey

A Data analysis was performed under Data analysis and the requirements needed can be found in Product specifications.

Survey2 was created to finalize the design based on the users needs and wants as well as to help determine our products success.

Society

Automatizing recycling will shift the topic from a widely recognized theme to an issue to be solved by experts. Recycling campaigns will likely get far less attention than they do now and did in the recent past. This might slightly counteract the intended effect of increasing recycling. These effects seem unlikely to outweigh the advantages gained in the efficiency of sorting, however. There will also be a shift of who holds the responsibility for recycling. This responsibility is currently largely held by the consumer who is expected to throw garbage into the designated bins. If this process is largely automated the responsibility will either be carried by a few enterprises or, shared among society as a whole if the adoption of smart bin is facilitated through government owned utilities.

Enterprise

Recycling firms are struggling to be profitable in large part due to expensive and inefficient separation of waste feed-streams. An automated bin will judge much more accurately which products are likely to be recyclable than the average consumer. This improved recycling prior to waste collection would drastically lower the cost of recycling and increase profitability of these plants, therefore encouraging new investments into such businesses. The increase of separated waste arriving at recycling plants rather than landfills will also allow for these plants to invoke the economics of scaling up to further increase profitability, making such businesses even more attractive. It is thus likely that widely accessible smart bins will grow the recycling industry.

Planning

Approach

Solving one of the recycling problem aspects has a difficult set of objectives: first, the team must evaluate if a smart trash can is a suitable solution or if there are easier ways; the implementation is next in line. Our goal is to first design the bin with: all the necessary instructions, design of the smaller components, draw the circuits, write the code; everything necessary to build the smart bin if we had the resources.

Milestones

A certain milestone of the problem is finding a suitable way, preferably non-contact, to detect the trash that is put inside the bin; choosing the method depends on dividing the type of trash in the right categories, setting certain features of trash that the bin must detect. Next, the method must ensure it takes little time such that the bin can cope with high demand. Another milestone would be to make the bin robust to deviations from the model (it can happen that 2 types of trash are scanned together or it can happen that the queue of trash to be sorted becomes too long). The biggest milestone of the project is to actually finish the development (on paper) at the end of the 2 months.

| Week number | Tasks |

|---|---|

| Week1 | Background study |

| Week2 | User survey and factory study |

| Week3 | Preliminary design, make specifications of the product |

| Week4 | Design and make model, chose sensors, decide which part to focus on, study on sensors |

| Week5 | Second survey for feedback |

| Week6 | Test sensors/actuators and mount to the bin (if applicable) |

| Week7 | Validation of the design, analyze limitations and prepare for presentation |

Deliverables

The output of the project should be a full description, including the methods (such as pseudocode) for implementing the idea. The description should ensure that anyone who will read it, follow the steps and buy the necessary parts can build the smart trash bin. This might change due to the complexity of the project to simply finding the right method to sort the trash by categories.

Task distribution

Week1

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [8h] | Learn wikitext[1h], Material sensors [5h]

[1] [2] [3] [4] [5] [6], Approach-Milestones-Deliverables [1h], look over internet for other ideas [1h] |

| Stacey Elshove[10.5h] | Learn wikitext[2h], Reasons why[7][8]and summary[4h], What already exists[9][7][10] and summary[4.5h] |

| Petru Radulescu[6h] | Learn wikitext[2h]; Objectives[1h]; Problem statement[1h]; Sorting systems[2h]... |

| Yiqin Hou[13h] | Papers about X-ray imaging[11][12][13][14]/Object recognition[15] searched and studied[7h]; summary of X-ray and coputer vision[2h]; Learn wikitext and make template for the group wiki[3.5h]; User aspect[0.5h] |

| Tobias Hilpert[14h] | Literature study into waste sorting[4h], Research into Infrared spectroscopy[8h], Learned wikitext[2h], Wrote Enterprise and Society aspect[0.5h] |

Week2

Subgroups

User survey form: Ana Maria Risnoveanu, Stacey Elshove, Yiqin Hou.

Recycling center: Petru Radulescu, Tobias Hilpert.

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [10.5h] | Two group meetings[3h], make the survey in Google forms [3h], distribute the survey [0.5h], first sketch of the bins digitally [4h]. |

| Stacey Elshove[6h] | Two group meetings[3h], Prepare questions, finalize and distribute Survey[1.5h], learn wikitext- links within a page and to external pages and add links[0.5h], edit wiki-User, Data analysis [1h] |

| Petru Radulescu[8h] | Two group meeting[3h], How the Dutch recycle[4], editing wiki[1h] |

| Yiqin Hou[8.5h] | Two group meetings[3h], Prepare questions and distribute the user form[1h], edit wiki[0.5h],think and sketch possible bin designs (the draft will not be uploaded to Wiki)[3h] |

| Tobias Hilpert[8h] | Two group meetings[3h], Research into Dutch recycling plants[2h], research into recycling mechanisms[2h], research into household waste composition[1h] |

Week3

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [7.5h] | Three group meetings[7h], part of feature analysis for the trash from the survey Basket categories,Size[30min]; |

| Stacey Elshove[8.5h] | Two group meetings[3.5h], Data analysis on Stata[4.5h], Survey 2 questions [0.5h] |

| Petru Radulescu[h] | Three group meeting[7h], Fun to recycle[1h] |

| Yiqin Hou[9h] | Three group meetings[5h], General plan made, possible problems or hazards listed[1h], Analyze replies of question: "What do you recycle?"[1h], Adjust product specifications according to data analysis results and merge hazards into the form[1h], New sketch of the bin: Sketching[1h] |

| Tobias Hilpert[6.5h] | Two group meetings[3.5h], Exploratory data analysis in Python [3h] |

Week4

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [13h] | Meeting with Petru to discuss about flaws of design and write down documentation for the latest model [4h], try to sketch the bin in illustrator (but failed) [1h], update wiki with the information about the latest model but the work was not saved by wiki[4h], repeat last task [4h] Model description |

| Stacey Elshove[7.5h] | Two group meetings[4h], make paper prototype[1h], edit the requirements under Product specifications to requirements and could have [0.5h], Survey2[2h] |

| Petru Radulescu[8h] | Two group meetings[4h], Meeting with Ana to discuss about flaws of design and write down documentation for the latest model [4h] |

| Yiqin Hou[5.5h] | Two group meetings[4h], make sketch version 3.0 in Sketching[1h], eidt list of components[0.5h] |

| Tobias Hilpert[9h] | Two group meetings[4h], Organize Lab access to the Analytical Lab in Helix [2h], Discuss plan for experiments with Wilco Wegemans (supervisor of the Lab) [2], collect first samples [1h] |

Week5

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [5h] | Two group meetings[4h], look into different possibilities for the animation [1h] |

| Stacey Elshove[10h] | Two group meetings[4h], correct wiki text (spelling, consistency, overlap) [4h], start on the presentation [2h] |

| Petru Radulescu[5h] | Two group meetings[4h], look into different possibilities for the animation [1h] |

| Yiqin Hou[7.5h] | Together with Week6 |

| Tobias Hilpert[17.5h] | Two group meetings[4h], Sample preparation, Machine calibration and Measurements [7h], Data Analysis with Essential FTIR and Database research [6h], summarizing results [0.5h] |

Week6

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [8h] | tutorials for Blender [4h], tutorials for Simscape [1h],weekly meeting with supervisors [30min], subteam conversations [30 min], upgrade and install on Matlab [2h] |

| Stacey Elshove[7h] | Data analysis for survey 2[1h], correct wiki text (spelling, consistency, overlap) [2h], work on presentation [4h] |

| Petru Radulescu[8h] | tutorials for Simscape [2h], work in Simscape [4h], tutorials for Blender [1h], weekly meeting with supervisors [30min], subteam conversations [30 min] |

| Yiqin Hou[7.5h] | Steps of construction: steps.docx[10h], Look into different motors and search for methods of control[5h] |

| Tobias Hilpert[h] |

Week7

| Name[total hours of work] | Tasks and hours |

|---|---|

| Ana Maria Risnoveanu [h] | Group meeting [2h], |

| Stacey Elshove[9h] | Group meeting [2h], Data analysis for survey 2[4h], work on presentation [3h] |

| Petru Radulescu[h] | Group meeting [2h], |

| Yiqin Hou[4h] | Group meeting [2h], Edit wiki [2h] |

| Tobias Hilpert[h] |

Literature and research

Reasons why

Too much rubbish

Nowadays there is an over load in rubbish in cities and in rubbish dumps, he main reason for this is that there are many recyclable materials that just get throw away in the normal rubbish. Having smart bins will help reduce this waste and the resources we use to make produces. Sharma and Singha, [7] found that the pile up of rubbish is leading to many diseases and came up up with a solution about a Smart Bin that will alert the collector when the bin is full and they will come a collect it. This will prevent rubbish over load for example, rubbish falling out of bins or piling up next to them because they are full. However this is just a start to our problem as this still does not solve the recycling issue, this is dealt with in the next section.

Easy to recycle

The best way to get people to do things is to make it easy for them to do it. When it is easy to do something people are more inclined to do it than when they would have to put lots of effort in for example to have to take their separate plastics bag to the supermarket to recycle it when they could just add it to the normal rubbish.

Lack of knowledge

Thomas etal, found that many people are unaware of what happens after they throw something away, or the benefits of recycling[8]. Creating more awareness will cause people to understand what their actions will lead to and hopefully impact the way they behave.

Fun to recycle

When something is fun to do as when it easy to do people are more inclined to do it. This can be seen in the Efteling in the Netherlands, they have paper bins which are shaped like people who have their mouth open. People can through paper into their mouths and then they are thanked for recycling (feeding them). This make people more inclined to recycle as now it is fun to throw the paper into his mouth and they also receive positive feedback.

Another idea is to create an accompanying app that can comper your recycling proficiency with your friends or other people from the same city. This could make the process of recycling competitive pushing owners to do it more thoroughly and maybe give potential customers enough incentive to do the final step. Such systems are used in smartwatch products like Fitbit.

What already exists

Bin e is a smart bin that sorts anything you throw away[9] . It sorts the items into plastic, glass, paper and metal. This bin is only for recyclable materials thus people still have to put some thought into whether they can recycle it or not. As mentioned above the Smart bin[7], which informs the collectors when it is full. The bin uses Ultrasonic sensors to determine how full the bin is. Wireless Sensor Networks exist to monitor the level of the bin, if it full or half full or empty[10].

How the Dutch recycle

There is a curbside collection service that collects: [16]

- Biodegradable waste in the green bins (almost all cities)

- Paper in yellow bins (almost all cities)

- Plastics in blue bins (major cities)

- Household chemicals, batteries in red bins (most cities)

- Clothing in green clothing containers (most cities)

For example, the cities of Eindhoven, Valkenswaart and Geldrop-Mierlo employ the company “Cure Afvalbeheer” to collect refuse and waste paper and recycle it into new products. Cure takes care of the collection of waste paper and cardboard, plastics, bulky household waste, glass and chemical waste.[17]

On the collection of recyclable waste: [18]

What paper can be recycled:

- Newspaper and fliers

- Copying, writing, drawing paper

- Envelopes

- Gift-wraps

- Egg boxes

- Paper bags and cardboard boxes

- Cardboard and paper packaging

What plastics can be recycled:

- Plastic bags and bread-, pasta and rice bags

- Wraps from magazines and advertising materials

- Plastic trays

- Yoghurt, cream and ice cream pots

- Plastic lids from jars

- Plastic bottles (from drinks, cooking products and sanitary products)

- Shampoo, shower gel, hand soap and bath foam bottles and similar

What glass can be recycled:

- Glass packaging of beverages

- Glassware of food (jars)

- Glass packaging of cosmetics

- Glass packaging of medicines

- Glass deodorant rollers

- Perfume bottles

What textile can be recycled:

- Clothing

- Bath towels

- Sheets, blankets

- Kitchen textiles

- Curtains

- Shoes (paired together)

- Bags, belts and scarves

What chemical waste can be recycled:

- Batteries, low-energy light bulbs, light strips, liquid drain cleaner, lamp oil, kerosene, pesticides/ herbicides/insecticides

- Medicines, mercury thermometers, injection needles

- Paint, varnish, stain and wood preservation agents, products used when painting such as turpentine, thinner, paint stripper, paintbrush cleaner, paintbrush softener and benzene, mercury switches

The percentage of different wastes collected in the Netherlands: [19]

Recycling firms in the Netherlands

Existing facilities

The market for waste consists of consumers, collectors, processors and disposers. Collectors in the Netherlands are contractors hired by local municipalities or services directly employed by said municipallities. [21] Depending on the size of their waste streams industrial facilities may either employ the local services or hire a private waste collector. This choice is still regulated on the provincial level [22] by the distribution and requirement of permits. Collected waste is then further distributed to processors, who recycle waste streams into new secondary material, and disposers, who make use of landfilling and incineration to remove the unrecyclable waste. There are close to 600 individual recycling facilities and support firms located in the Netherlands [23] recycling wood, metals, plastics, paper, electronics and glass. This large presence of companies lead to a substantial import in recyclable waste into the Netherlands in recent years [24].

Recycling mechanisms

Recycling mechanisms naturally differ largely by the type of waste inside a given waste stream.

Metals

In the Netherlands most ferrous metals are directly sorted from general waste with the help of electromagnets, whereas pure sources of non-ferrous metals, most notably aluminium, are collected separately. Both kinds are then processed in a similar way, first being compressed for transport, then shredded for sorting and more efficient melting. The melted metal is then purified, usually using electrolysis. [25]

Paper

Paper waste is grouped into several different groups depending on the kind of paper and the print on it. These groups range from wood-free white paper without print to wood-containing coloured or heavily printed paper. The recycling mechanism differs for different categories, but usually includes multiple washing, kneading and dewatering steps. The main difference between the categories is the number and placement of deinking steps [26].

Organic

Organic waste is most commonly recycled by the use of Composting, Bio fuel Production or Algae Production, the latter being the least common in the Netherlands [27]. Most household waste are categorized as solid food spills and are converted into bio gas in anaerobic bioreactors [28].

Plastics

There are close to 40 plastic recycling plants in the Netherlands. About 1/3 of these facilities accept a wide range of different plastic types, including PET, PP, PS, HIPS, PVC, HDPE, LDPE, ABS, and PMMA. The most common types present in household waste are PET, PP, and PE (both HDPE and LDPE). Most of the other facilities specialize in one more of the these common plastics. [29]

Waste composition

A comparison of the waste composition of both produced and recycled solid waste is given below:

| Kind of waste | Amount collected [/person/year] | Amount recycled (percentage) [/person/year] | |

|---|---|---|---|

| Biological | 144kg | 86kg (60%) | |

| Paper | 66 kg | 52 kg (78%) | |

| Tetrapaks | 3,6 kg | 1,8 kg (50%) | |

| Glas | 28 kg | 20 kg (73%) | |

| Plastic packaging | 25 kg | 14 kg (59%) | |

| Metal cans | 7,1 kg | 6,7 kg (95%) | |

| Electrical equipment | 18 kg | 9 kg (49%) | |

| Textiles | 15 kg | 4,7 kg (31%) | |

| Small chemical disposables | 1,4 kg | 1,2 kg (86%) |

There are notable deficits in the recycling statistics in biological waste, Tetrapaks, plastic waste, electrical equipment and textiles. The drop in percentage point for electrical equipment and plastic packaging can be explained by the complex recycling processes necessary for these materials [31]. Biological waste and Textiles, however, are recycled with relative ease. These deficits are mainly due to improper collection of the waste streams: bio-waste is difficult to separate from general waste and textile collection is difficult for the consumer.

Detection

X-ray

Inspired by security machines, X-ray imaging could be a usefull tool in detcting the type of rubbish. X-ray imaging [13]makes use of the property of X-ray that it attenuates differently accorss difderent materials. For example metal atoms and ions attenuate more X-ray than normal organic tissue, such as fat and protein. Some new X-ray imaging techniques could even determine the chemical structures that form within the materials[14]. With such techiniques and some morden X-ray imaging detectors [12], the bin can distinguish materials much more accurate than using normal X-ray imaging. It is also possible to distinguish different types of plastics with X-ray imaging[11], which further increases the recycling sorting process.

Despite its reliable performance in detecting metal and different kinds of organic materials, an X-ray imaging system is too expensive to implement in a household trash bin. Even the cheapest X-ray tubes cost $100 to $500 each, let alone the detectors, power supply and other systems.

Computer vision and image processing

An alternative could be object recognition, by simply mounting a camera in the container and train an AI system to recognize different types of wastes. With the technique of using discriminative parts[15], the system could be even more precise. For example, it can distinguish the words on the package of the waste. Computer vison could be implemented together with other techniuqes like infrared spectroscopy, to increase overall effectiveness.

Infrared Spectroscopy

Infrared spectroscopy can be classified into different categories based on the wavelengths used. This detection method is both cheap and fast enough for practical applications in waste sorting. Near Infrared (NIR, wavelength 1-1.7µm) Spectroscopy is already deployed for uses in plastic separation. NIR has the ability to excite overtones of molecular vibrations and therefore can give information on the chemical composition of the sample. [32] NIR spectroscopy can also be used for different kinds of waste, such as construction debris [33]. There are clear limitations when analysing black and coloured samples though, as their reflectivity in the NIR spectrum is too low to allow for signal-to-noise ratios high enough for proper identification. To overcome this difficulty NIR spectroscopy can be enhanced with longer wavelengths. It has been shown that combining NIR with Midwave Infrared (MWIR, wavelength 3-12µm) significantly improves the performance of detectors for black and opaque products. [34] This can be extended to multiple spectra in hyperspectral imaging techniques, which probe a wide range of wavelengths even in the visible spectrum for material identification. These systems have also been shown to work at the speeds which would be needed for practical applications. [35] FTIR spectrometers are simple enough devices that handheld versions with sensitivities good enough to separate materials exist. [36].

Available sensors

There are several sensors available on the market: electro-mechanical, pneumatic, magnetic, inductive, capacitive, photoelectric, ultrasonic. The electromechanical sensor only shows how resistive an object is, which might be important but not sufficient here since two different objects could output the same value [1]. The same is the case with a pneumatic sensor, which just differs in the way it is built [2]. The magnetic sensors are of no use since there is no magnetic field created by rubbish [3]. On the other hand, although it also uses an induced magnetic field, the inductive sensor (also known as inductive proximity sensors) may prove successful in the detection of metallic materials. Unfortunately, domestic trash mostly includes other types of materials and aluminium cans, for instance, are usually recycled in waste. Then, there is little difference between the applications of inductive and capacitive sensors [5] and spending time in choosing between them will only be useful if the team decides on the categories of rubbish. A photoelectric sensor is another proximity sensor, which can only be used to check the absence of an object which leads to the last option on the list: ultrasonic sensors. Although these sensors cannot detect different types of materials, they do offer more information: the distance to an object or the speed of the object; they are reliable and can be used in many applications [6]. Some models of ultrasonic sensors come with detection of some aspects of the material (softness, colour) and therefore they are the best choice among simple and cheap detection methods. In order to know if they are a suitable choice, we must set the desired sensitivity of our system and check the limitations of different ultrasonic sensors.

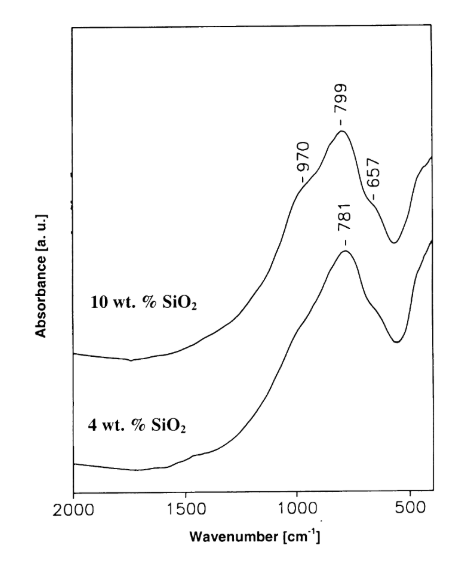

Experimental Testing

In order to determine whether our design is indeed feasible we decided to test the sorting mechanism in depth. From our previous literature research it was indicated that IR-spectroscopy was the most likely candidate to be used in the sensing area. Although an (FT-)IR spectrometer might not be the only sensor in the final design a large portion of the sorting will be determined by it. We have designed some experiments to test the feasibility of and FTIR spectrometer as sensor for trash sorting.

General Methods

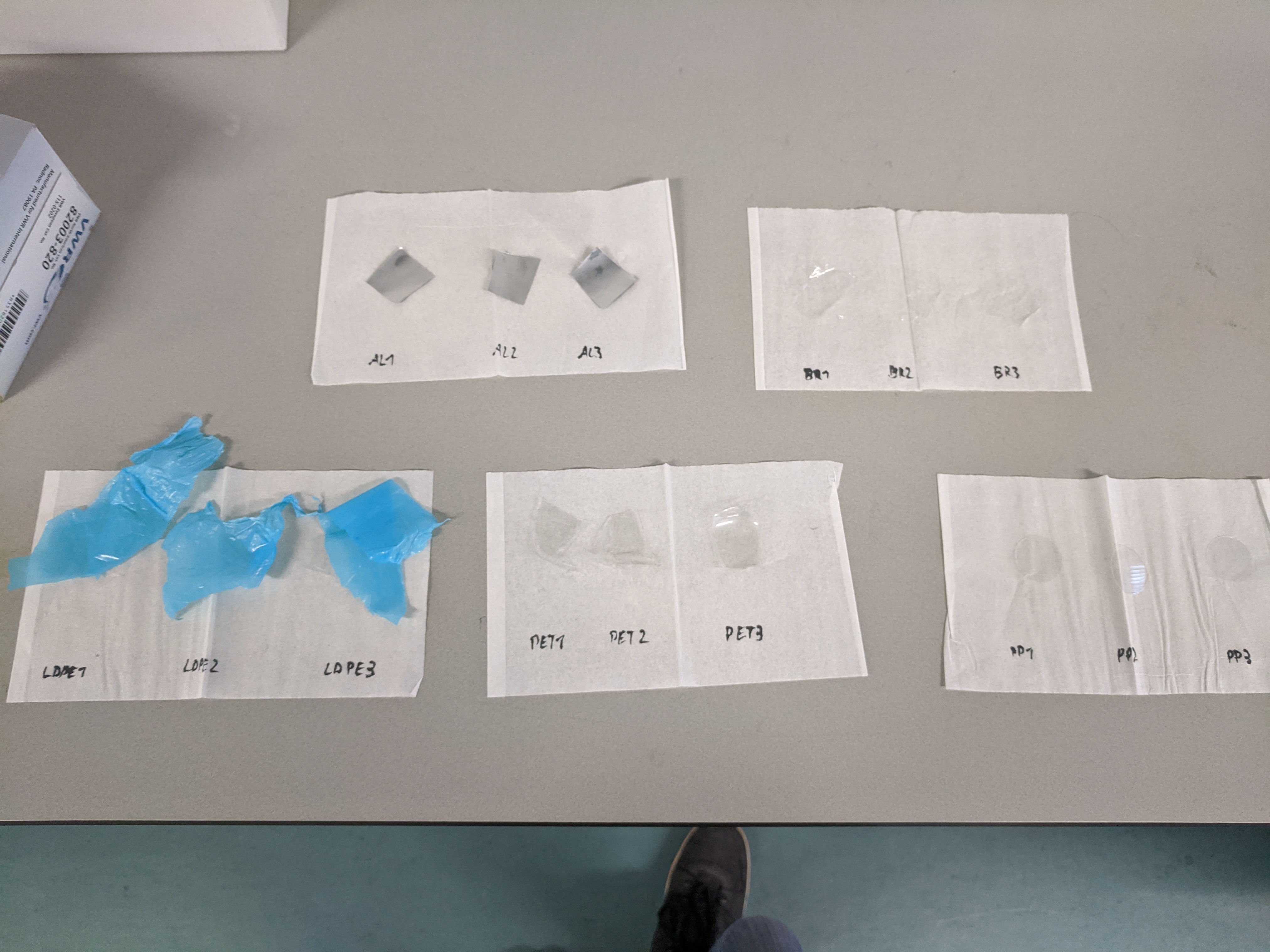

Samples were collected throughout a normal work week from used household items before they were thrown into the trash to mimic the samples likely to be encountered in the smart bin closest. They were stored in a PE container cleaned with Isopropanol for no more than 4 days. The samples were cut into 3cm2 pieces for the analysis. All measurements were carried out on an IRAffinity 1 equipped with a MIRacle 10 ZNSE prism plate, both supplied by Shimadzu.

Before the measurements were taken the machine was calibrated by 256 scans of the detected IR radiation from diffuse environmental reflections. In order to guarantee accurate measurements each sample was scanned at least 56 times. The lens tray was thoroughly cleaned with Isopropanol between each measurement. All data analysis was performed in the Essential FTIR (v3.50.194) environment by Operant LLC.

Experiments Week 5

The first round of experiments was prepared to iron out mistakes in the collection and measurement process as well as trying to identify different kinds of plastics.

5 different polymers were inspected: (Low density) Polyethylene (PE), Polypropylene (PP), Polyethylene Terephthalate (PET), Aluminium coated polyethylene (here: AL) and a biodegradable polymer (here: BR). For each polymer three samples were collected.

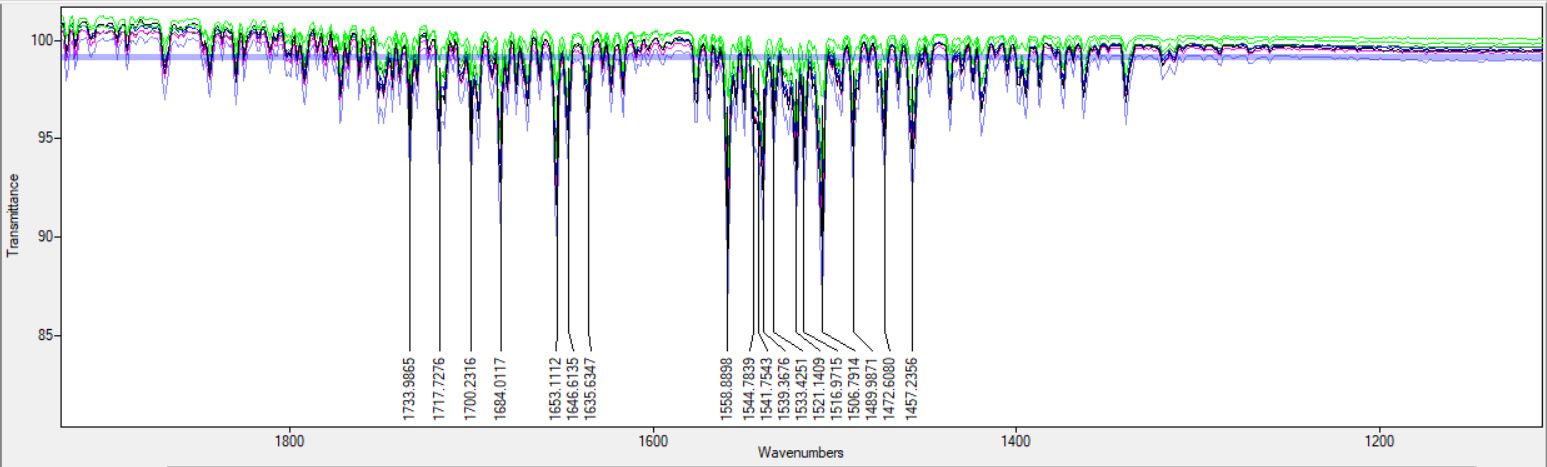

Each sample was scanned 56 times and the spectogram was then analysed.

Results and Discussion:

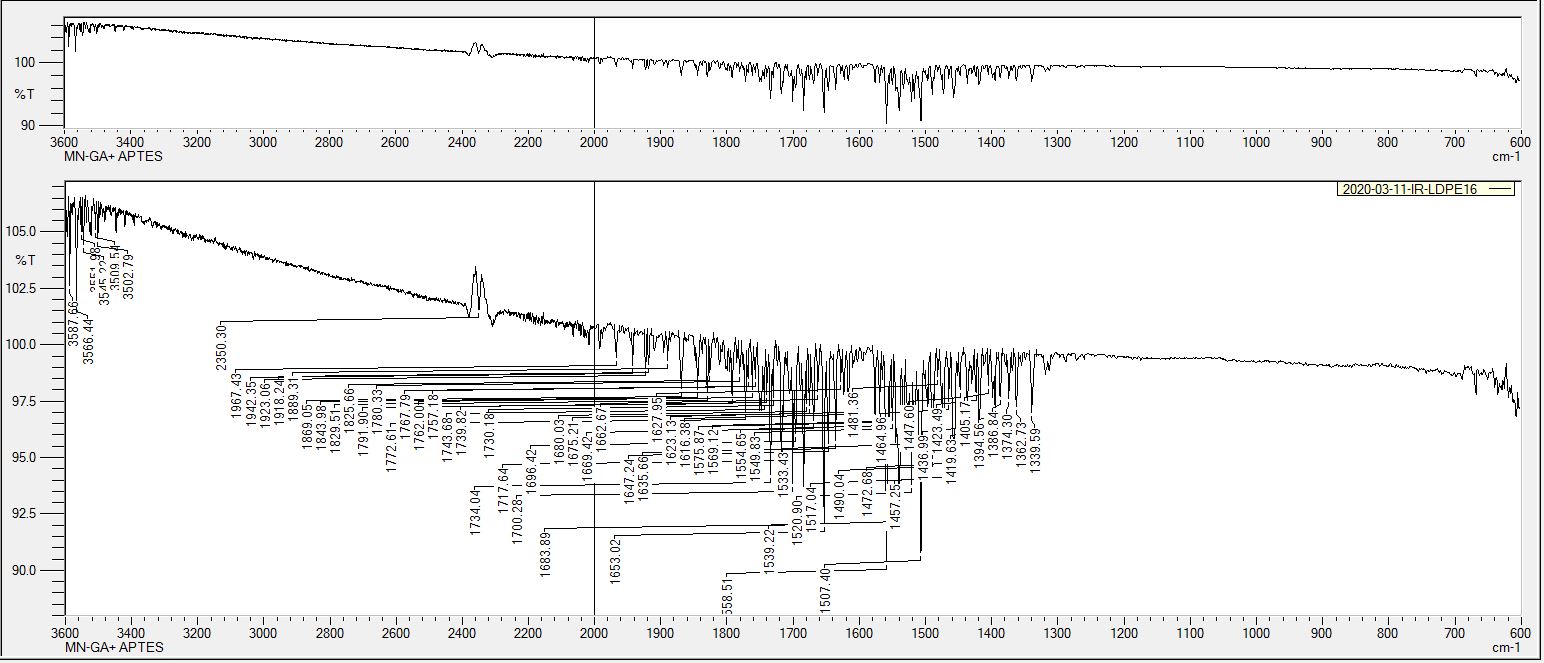

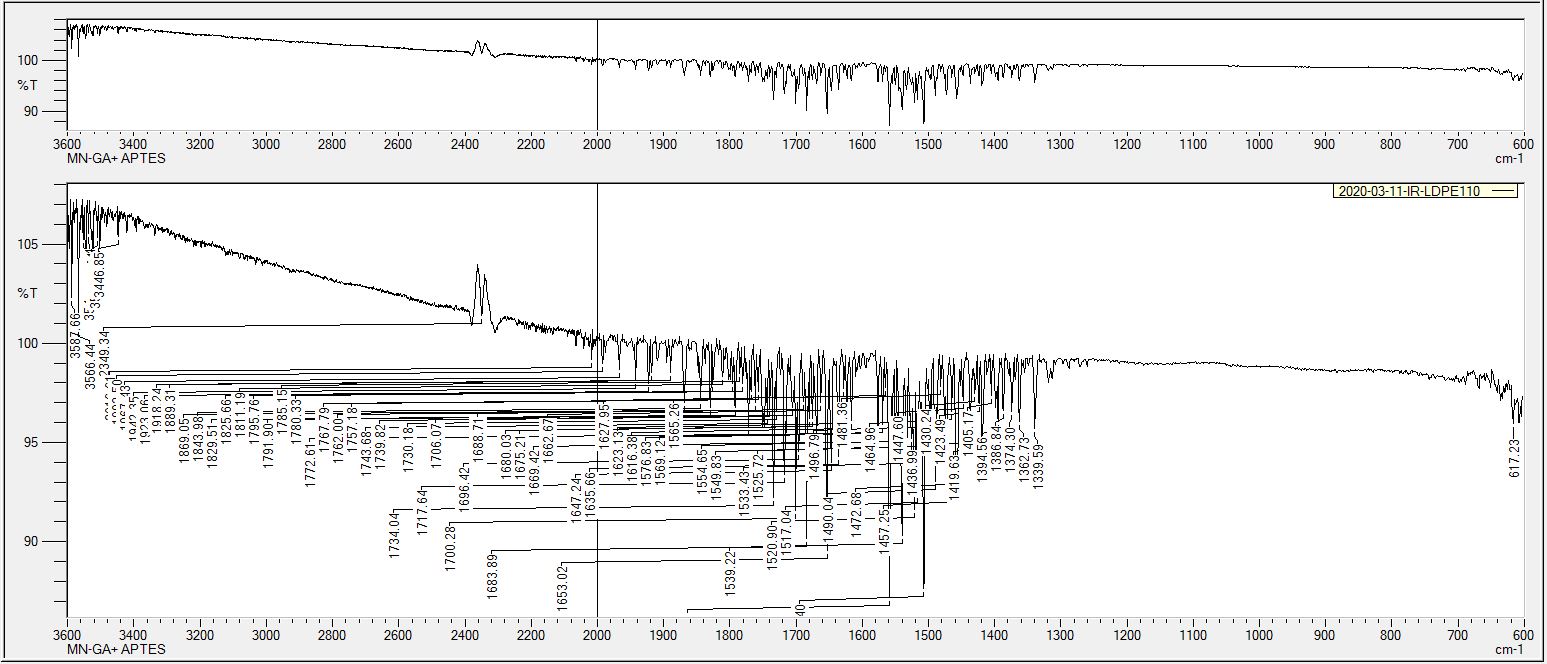

Every single sample showed very similar characteristic peaks, contrary to our expectations. The overlay of the first sample from each Polymer shows almost identical peaks at a cm-1 that do not clearly correspond to molecular vibrational overtones which should be present in all samples [37].

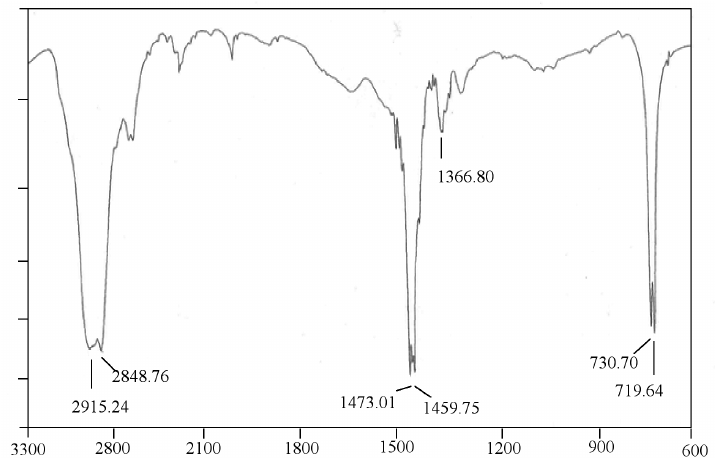

The results also seem to disagree with literature on multiple accounts. The IR-spectrum of PE agreed upon in literature, for example, shows a large deviation from our measurement.

Literature reports this spectrogram[38]:

Whereas the measured spectrogram shows different peaks:

Analogous disagreements were found for PP and PET as well. Especially the Biodegradable Polymer should pose a vastly different spectra than PE or PP. But they seem incredibly similar in our data:

This seems to point to a common contaminant in all samples. As they were collected and stored separately it is likely that the machine itself was polluted with a contaminant which could not be cleaned with Isopropanol. To get insights into the possible issue the spectra of LDPE1 and AL2 were compared with the NICODOM IR library[39], the SpecrtaBase library [40], as well as the Spectral Database (SPBS) [41] from the National Institute of Advanced Industrial Science and Technology (AIST) of the government of Japan.

The first two libraries resulted in no valuable candidates, but the SPBS found hits for the compound 2-methyl-6-(2-(5-nitro-2-furyl)vinyl)-1,2,4-triazine-3,5(2H,4H)-dione, indicating that this substance might have polluted the measurements.

Spectra of waste classes

Due to the measures enacted because of the Coronavirus pandemic further experiments could not be carried out as all Labs, including the one specialised in analytical chemistry were shut down. To complete the evaluation of the infrared sensor anyway a detailed literature study was performed to investigate the expected spectra of each waste class to see if they can be differentiated. Note that this data is often collected if a vastly different context than waste management, meaning that especially expected pollutants in the samples which could be taken into account with our experiments could not be reproduced by research. Nonetheless the research yields very informative insights into the validity of the sensor.

Glass

Glass is primarily composed of Silicon dioxide which is arranged as a macroscopically unstructured, three dimensional polymer with a tetragonal unit cell. In waste glass can be separated by colour. The colouring is achieved by low concentration additives however, showing little disturbance in the infrared spectra. [42] The random arrangement of glass leads to a range of different Oxygen coordination numbers. Notably for household glass, both [SiO4] tetrahedra and [SiO6] geometries can be formed. The ratio of coordination numbers can give insight into the stresses incorporated in the glass. As the different molecular geometries result in different bond lengths, they vibrate in different modes – making it possible to investigate this composition by FTIR spectroscopy. If this detail can be found with the FTIR sensors just identifying glass seems highly possible. The important spectral bands are at 1110, 802, and 474 cm^-1.

figure obtained from [42]

figure obtained from [42]

Even different kinds of glass can be diffrenetiated. Inclusion of glass in organic waste streams can severely disrupt the process of converting waste into fuel. For this purpose NIR spectroscopy has been used to identify down to 2vol% glass in different organic waste streams.[43] The ability to gain this high resolution for glass identification seems very promising for separating it in household waste. The fundamental Si-O stretching vibration can be exited with a IR wavenumber of 1110cm^-1. To conclude whether the spectra of glass can be accurately measured quickly enough literature is also insightful: “Due to its high absorption coefficient, the Si–O stretching absorption IR band observation requires extremely thin specimens while the observation of the corresponding IR reflection mode at 1122 cm^-1 can be made conveniently even for bulk silica glass samples since the latter probes only a thin surface layer of the specimen. Both the IR absorption band at 1100 cm^-1 and the IR reflection band at 1122 cm^-1 are due to the asymmetric stretching vibration of the Si–O bond.” Quote obtained from [44] This shows that reflective FTIR will have no problems measuring the characteristic wavenumbers of glass. From this it is possible to conclude that household glass can be identified by investigating the measured spectra at 1100cm^-1.

Paper

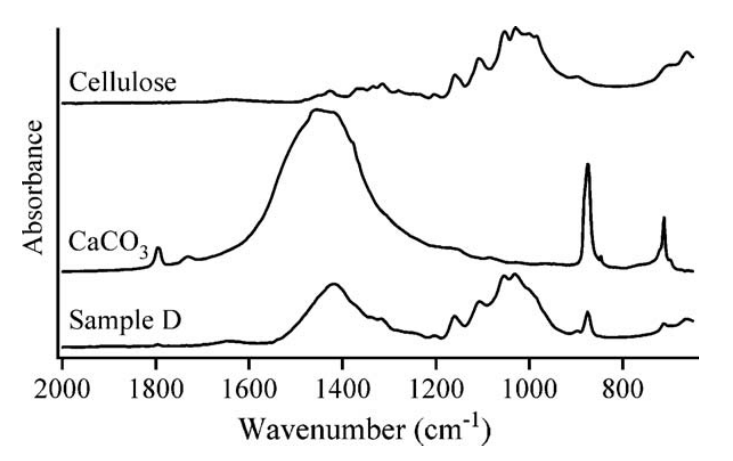

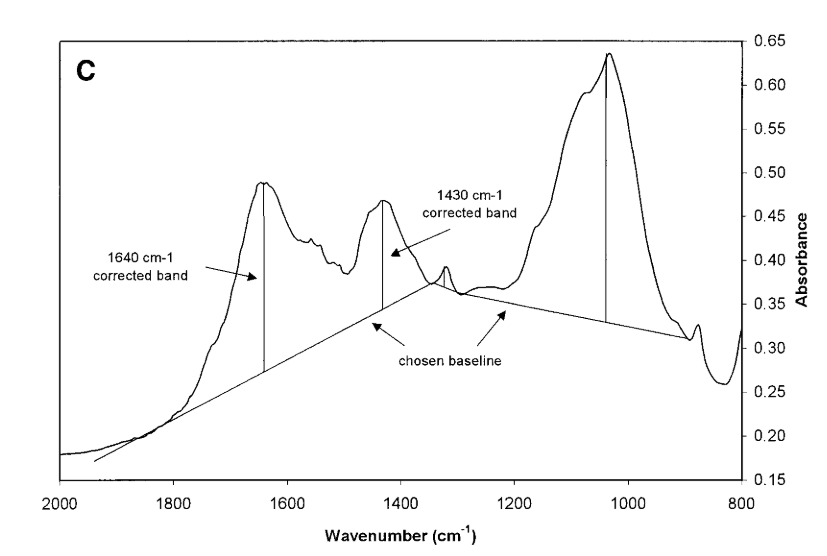

Paper waste composes a large fraction of household waste. The main component of paper are thin cellulose fibres, which might yield similar spectra to some organic wastes, especially hard vegetable stems. A main challenge in paper recycling is wide variety of paper finishes available today. Each colourant might influence the IR spectrum in a unique way which could be hard to identify. Additionally, highly reflective, thin plastic films could further complicate the identification. Here a simple rule of thumb comes into help: “If it’s hard to identify it’s hard to recycle”. This statement is easily proven by realizing that both difficulties stem from one source: a complex molecular structure of a wide range of compounds (see section for recycling processes). [45] The identification of paper has been thoroughly researched for forensic purposes. In literature it has been found that almost all office paper includes CaCO3 as filler which significantly influences the Absorbance spectra:

figure obtained from [45]

figure obtained from [45]

Most characterising features are found in the region between 700 and 1600 cm^-1. The paper describes the graphic accurately: “Calcium carbonate produces a band at about 1420 cm^-1 and two peaks at 880 and 712 cm^-1. These correspond to the asymmetric C–O stretching mode, to the symmetric C–O stretching mode and to the OCO bending (in-plane deformation) modes, respectively, of calcite. Cellulose is characterized in this region by a main band composed by several signals. The peak at 1160 cm^-1 corresponds to the asymmetric ring breathing, the signal at 1107 cm^-1 is due to glycosidic C–O–C stretching vibration, and finally the bands at 1055 and 1031 cm^-1 are due to C–OH stretching vibrations of secondary and primary alcoholic groups of cellulose, respectively.” The main peaks of Cellulose excitations overlap for a significant fraction with the spectra of SiO measured for glass. However, the broad peak at 1400cm^-1 can be used to easily separate the two. [46] The paper finishes can also be classified if the spectra is measured with enough resolution. This requires advanced data processing techniques like kNN clustering, however. It is infeasible to perform these calculations locally in the smart bin. The influence of the coatings on the overall spectra was proven to be minimal, however.

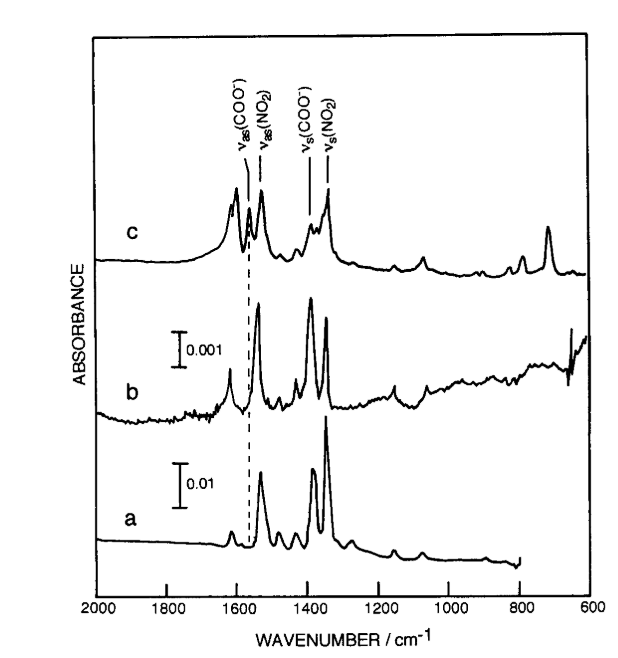

Metals

Metals are composed of periodic lattices of atoms with no clear directional bonds. Vibrations in metals do exist and are described as Phonons. For most metals these phonons cannot be excited by infrared photons, however. [47] This makes it difficult for FTIR spectroscopy to gain any valid insight into the actual composition. For this reason most literature on IR spectroscopy of metals focuses on the detection of organic impurities or various surface pollutions. [48] Due to their highly reflective properties metals are sometimes used as enhancement to measure the spectra of different organic compounds. In the figure below the organic molecule nitrobenzoic acid is measured on a different surface (c) and adsorbed on metals (a) and (b). As shown below the metals introduce close to no new peaks to the spectrum. From this it can be inferred that the presence of metals can be detected by the absence of visible spectral peaks.

figure obtained from [48]

figure obtained from [48]

The effect described it the paper above might be detrimental when metal which served as food container is being analysed. The leftover food in the container could act just like the molecule adsorbed to a metal substrate, leading to an amplified signal of the leftover food instead of one classifying the metal container. There might be a possibility to identify metal samples based on their surface plasmons. This technique is not well researched, however.[49] In summary metals might pose a significant challenge to be measured by IR spectroscopy as they’re effectively transparent to the relevant wavelengths and might amplify the spectra of surface pollutants.

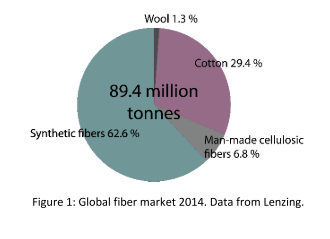

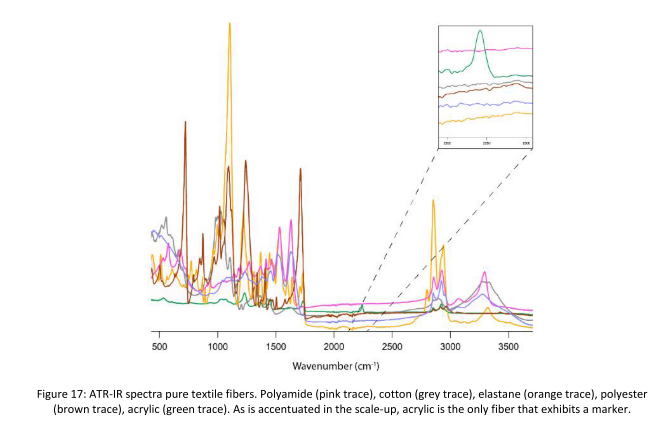

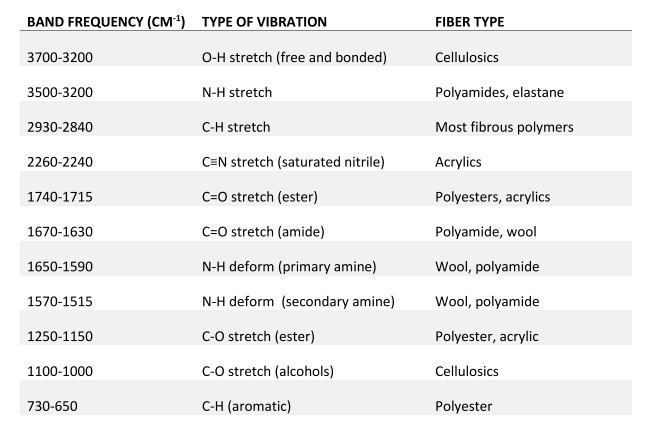

Textiles

Textiles are fabricated of a wide variety of fibre types classified by their different compositions. A given textile product may contain multiple types at once. The most common categories are Cellulosics (cotton), Protein fibres (wool) and Synthetic fibres. Synthetic fibres consist themselves of a wide range of different polymer types, including Polyesters, Polyamides, Polyacrylics and Polyurethanes (Elastane).

figure obtained from [50]

figure obtained from [50]

This wide spread of individual molecules might make classification in individual categories ambiguous. Protein fibres, for example, might prove to be indistinguishable to food waste and synthetic fibres would yield very similar spectra to certain plastics.

figure obtained from [50]

figure obtained from [50]

The figure above shows the spectra of many common fibres. There are no striking similarities between the individual spectrograms. With a sensor of a high enough resolution and analysis of the full spectrum the fibres could be distinguished, however. As depicted, Polyacrylics are the only fibres showing a unique peak in a region where no other fibres are active.

figure obtained from [50]

figure obtained from [50]

A lot of the characteristic peaks of the fibres are shared with the peaks of many Polymers as well. [50] The minimum quantity to identify each fibre is surprisingly low, however.[51] Especially synthetic fibres are easy to separate if the sample is clean and the full spectrum is analysed. This might not be possible in the smart bin, however. Cotton fibres are pose no threat of confusion with synthetic fibres, but might be difficult to separate from paper due to both being mainly composed of cellulose. The additives mostly present in paper, are not commonly found in cotton trash though. [52] It is thus questionable whether synthetic fibres can be separated from plastics. If the infrared sensor has a high resolution fibres could be distinguished but this might be infeasible in a smart bin. Cotton can easily be separated from other fibres as well as paper.

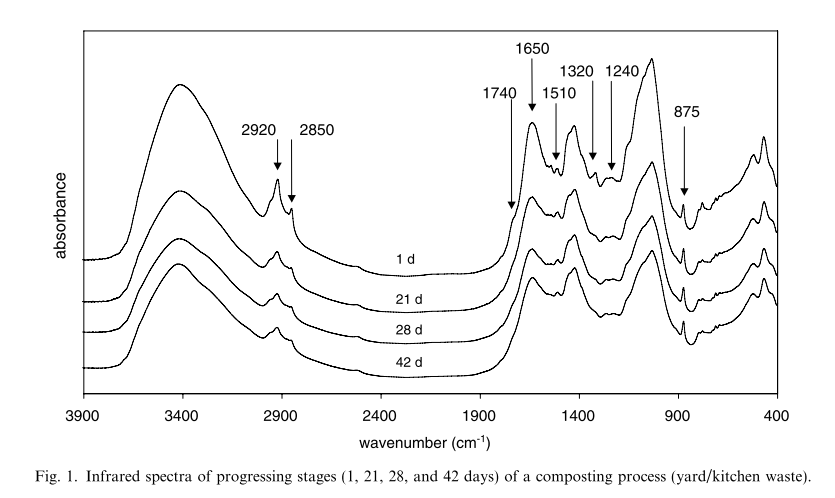

Organics

Organic waste in households is mainly categorized by food and garden waste. Both types show a wide variety of molecules present in each plant part of the waste sample. Identifying each molecule present in such a sample by FTIR analysis is a meaningless task. For classification and tracking of specific markers, however, FTIR spectroscopy has been found to be an insightful analysis technique. The quality of many liquid foods can be assessed through the tracking of food-specific biomarkers [53]. These biomarkers can be any range of biomolecules with very distinct molecular architecture. FTIR analysis can also identify the composting stage of organic waste [54]. Both tasks require much more resolution than the smart bin would need. The separation of organic waste seems very promising. Note that because of the wide variety of molecules present in organic waste samples measured IR peaks seem broadened out due to the many overlapping spectra.

figure obtained from [55]

figure obtained from [55]

[55] These broad spectra can be used to identify organic matter from the other waste classes, even if single molecules (cellulose, proteins) are present in both samples. Spectra of kitchen waste strongly resemble general organic waste and can be identified after many days of composting. [56]

figure obtained from [56]

figure obtained from [56]

All this shows that organic waste is easily separated from the other waste classes, mainly due to the lack of single characteristic peaks.

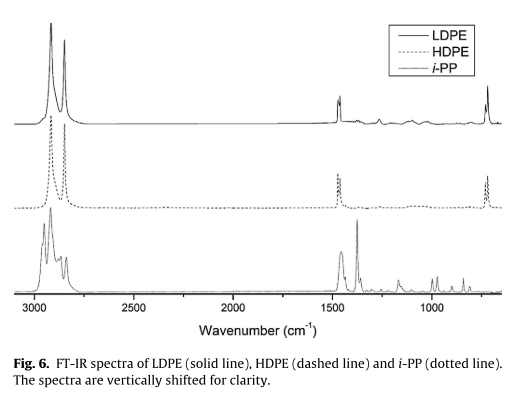

Plastics

Domestic plastic waste is mainly composed of five different Polymer types: PE (both HDPE and LDPE), PP, PS, PET and PVC. The multitude of other available polymers like ABS, PLA or HIPS are mainly seen in technical waste streams. [57] This means that the analysis can also focus on the Polymer types described above. Each type of these five plastics features a unique molecular structure which defines its infrared spectra. Individual polymer samples can easily be recognized. In fact there is ample literature written on the identification of polymers using FTIR spectroscopy. It is reported that HDPE and LDPE are virtually indistinguishable with regards to their characteristic peaks. The figure below illustrates that well. It also shows that PP can readily be split from PE due to the sharp peak at around 1300cm^-1.

figure obtained from [58]

figure obtained from [58]

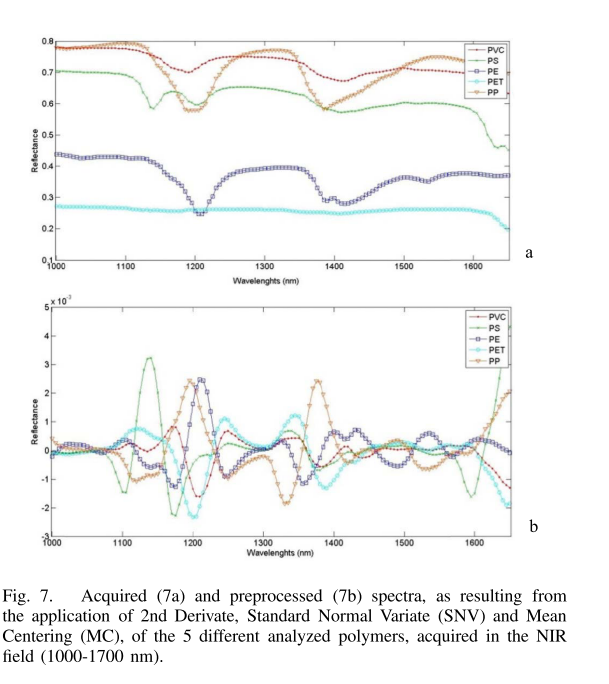

[58] This trend generalizes to the other polymers as well. Even in the restricted NIR region each sample shows characteristic shapes that distinguish it from the other molecules.

figure obtained from [59]

figure obtained from [59]

[59] Naturally the samples encountered in a smart bin will not match clean lab conditions. That Infrared Spectroscopy can be used to classify plastics even after they have been used is also demonstrated in literature. A range of plastic bags have been analysed detailed enough that the original manufacturer of the bags could be identified after use [60]. The spectra obtained from these sources are naturally less pure than cleaned samples and might show additional peaks corresponding to pollutants.

figure obtained from [61]

figure obtained from [61]

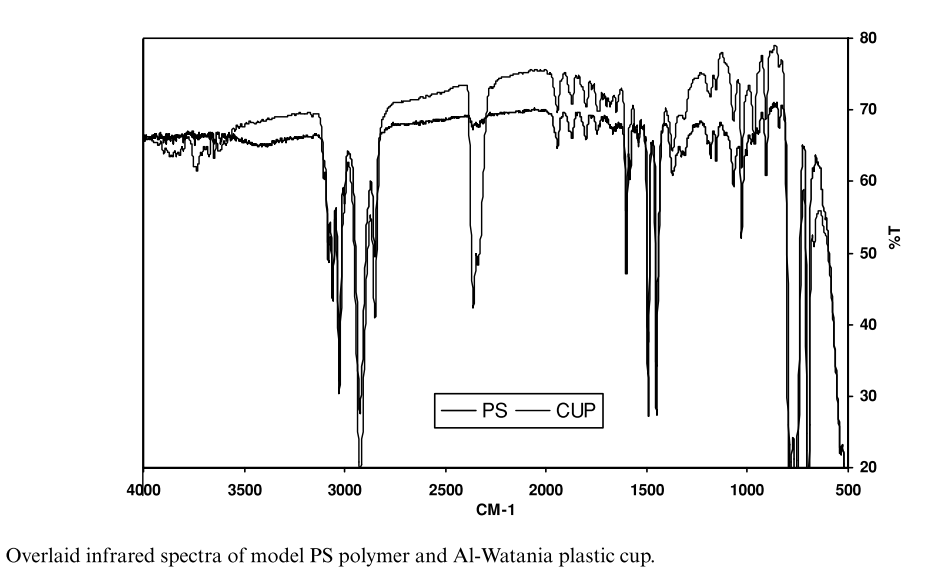

The figure above is an example of a clean PS spectra overlaid with the spectra of a used plastic cup made of PS. The cup shows all characteristic peaks of PS, but also an additional unexpected peak at 2400cm^-1. [61] Many household items are composed of plastic blends. Especially packaging of delicate foods often requires blends or multilayer packaging. These more complex spectra can also be identified using FTIR spectroscopy.

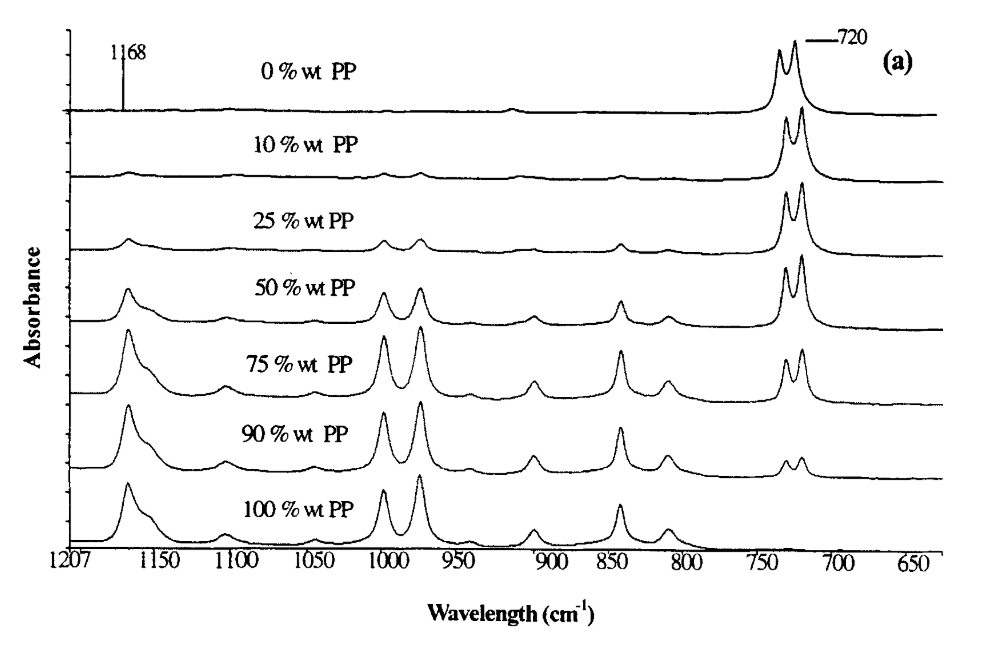

figure obtained from [62]

figure obtained from [62]

Polymer blends, as shown above with the example of a PP/HDPE blend, simply combine the spectra of the pure polymers. [62] This means that recognizing the characteristic peaks of pure polymers is enough to realize blends as well. Note that in all spectra shown above the Polymers were characterised by sharp peaks corresponding to their molecular vibrational modes. It is for this reason that even a blend of many polymers could be distinguished from organic waste through the broadness of the peaks. In general, Plastics are easily analysed by FTIR spectroscopy and can be distinguished from other waste classes even if multiple polymers are blended together or heavily polluted.

Summary and Conclusion

When viewing all waste classes together FTIR spectroscopy seems like a very viable sensing option. Glass, Paper, Organics and Plastics can easily be separated without the need for exorbitant resolutions. Textiles can be distinguished but synthetic fibres will be identified as plastics unless the entire spectrum is analysed carefully – which requires a more expensive sensor. This might not be suitable for the smart bin. Metals are difficult to identify based on IR measurements alone due to their near zero absorbance of infrared photons. The separation of metals from the other waste types thus requires additional sensing to gain more confidence.

Sorting systems

For sorting the trash itself the use of a conveyor type mechanism could be employed[63], such as a roller cylinder system that moves to create the right path to the corresponding bin for the trash.

Data analysis

Survey 1

Planning

First the summary provided by the google survey will be looked at and analysed. We will then dive deeper and analyse the data in the program Stata. The data will be checked and cleaned. One of the questions (Why is it difficult/easy to recycle?) will need to be analysed qualitatively, the rest can be analysed quantitatively. Correlations of variables can give more information about the effects they have on each other and what will be best for our users.

Summary

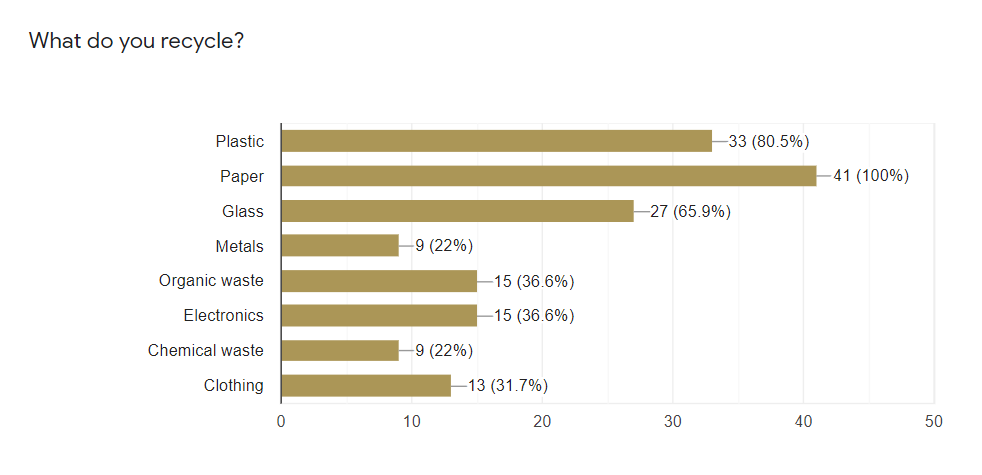

The summary shown on the Google survey shows, that most people do want a smart bin. 39% feel sorting their waste takes too much time or effort, this is shows that their is a need for this Smart bin. Around 70% of people would like all their waste collected and around 65% of people are willing to pay extra to have all their waste collected from this is could be said that people prefer when things are easy or done for them. Currently only 65.9% recycle glass and 22% recycle metal, this can show that there is a need for our Smart bin because around 70% of people do think that recycling is important which means they want to recycle but something is holding them back. From the question ,Why is it difficult/easy to recycle?, it can be seen that many people struggle to recycle because it is difficult to find or take it to the bins. If our smart bin would be implemented in many homes maybe more services would be provided to collect these recyclables because of the money that is saved from having to sort waste, this is something that would still need to be researched and investigated.

When asked about what do you recycle, 100% respondents recycle paper, most people recycle plastic and glass. The detailed result is shown in the figure below.

The minorities can be left out not only because few people recycle them, but also due to other reasons. For example, metals are usually mixed with other materials, which cannot be separated easily. Electronics are hard to detect, since they also contain different materials. Chemical wastes are very difficult to detect, and the price of Flase Negative is too high. Clothing can be easily separated manually so it is not necessary to include this type in the smart bin.

However, it does not mean only three categories are needed for the bin. One needs to be aware that not all papers can be recycled and there are also different types of plastic. Moreover, glass can be easily distinguished by people, the smart bin would not make the recycling of glass any more efficient. Combining with the information given in How the Dutch recycle, a more proper solution could be that, the bin contains four categories. One is for paper,one for PBD plastic, one for other plastics and one for wastes that cannot be recycled or detected by the bin. It is notable that, paper like cardboards should be excluded by the bin, because they can be easily sorted by people while takes too much space in a bin. The principle is that, the smart bin should not be made to detect everything, but aim to help users distinguish wastes that seem recyclable while actually are not, such as contaminated plastic, photos and milk boxes.

Analysis in Stata

The survey was closed on 19 February 2020. The data was downloaded and put into Stata, it was cleaned and then analysed. The Data analysis was done on Google drive Data analysis and only the main findings are found below.

At a first glance it is clear that there is a moderate correlation between how often people recycle and how important recycling is to them. This could mean that people want to recycle but something is holding them back. There is quite a strong correlation between how easy and how often people recycle. It can also be seen that people find recycling important but not easy to do as there is a very strong correction, this could be the something that is holding them back, it is not easy to recycle and people just may not have the ability or time to do it in the way it is currently being done. People who find it difficult to recycle seem to want our bin more as there is a strong correlation between how much you want the bin and how easy it is for you to recycle.There is a moderate negative correlation between how important it is to recycle and if they feel it takes a long time or too much effort to sort, thus a lot of people find it important and that it doesn’t take up a lot of time or effort. As this is not a strong correction there is still a need for our bin because some people still feel it does take a long time, according to the survey 39% said it takes too much time or effort.

From this we can see there there is a need for our bin and from looking at the responses about our actual product, it is clear that most people are not willing to pay too much for this product (50-100 euros). They would also not want to pay extra or too much extra to have all their waste collected, up to approximately 100 euros. A bin of 30l to 50l is best for the users needs according to their responses.

Exploratory Analysis in Python

The dataset from the survey was also analysed in Python using pandas, matplotlib and the SciKit Learn package to see if other correlations can be discovered. The full code can be viewed in a Jupyter Notebook on the same google drive (Link to download the notebook). While cleaning the data in case of multiple answers for a single question the geometric average was taken to supply a single numeric value.

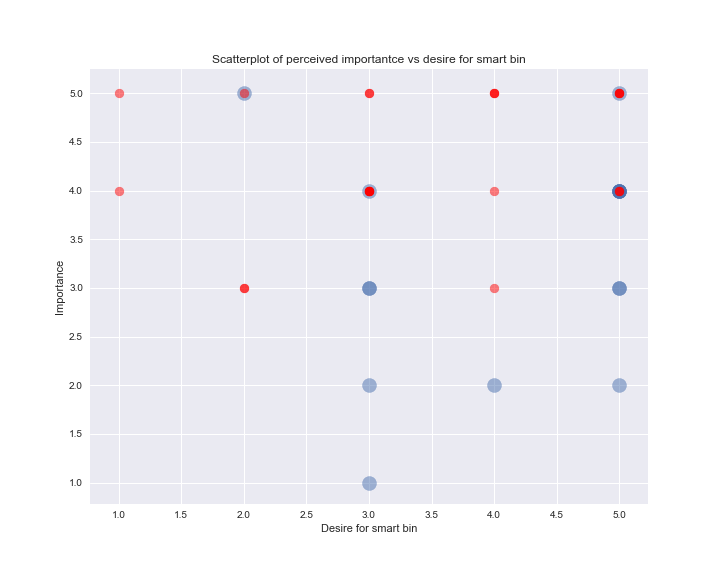

One notable finding is visualized in the graph below:

It depicts how important respondents perceived recycling vs how big their desire for the smart bin was. Additionally, red coloured dots correspond to respondents who answered that they do not find recycling too cumbersome, whereas blue coloured dot found recycling too difficult. A more opaque dot corresponds to multiple answers for a single value. The size of the dots is different for visualization purposes only and bears no statistical significance.

In the plot it is visible that mainly respondents who did not find recycling important and also found it too difficult have a strong desire for the smart bin. This defies the intuition one might have that respondents who consider recycling important have a high desire for a smart bin.

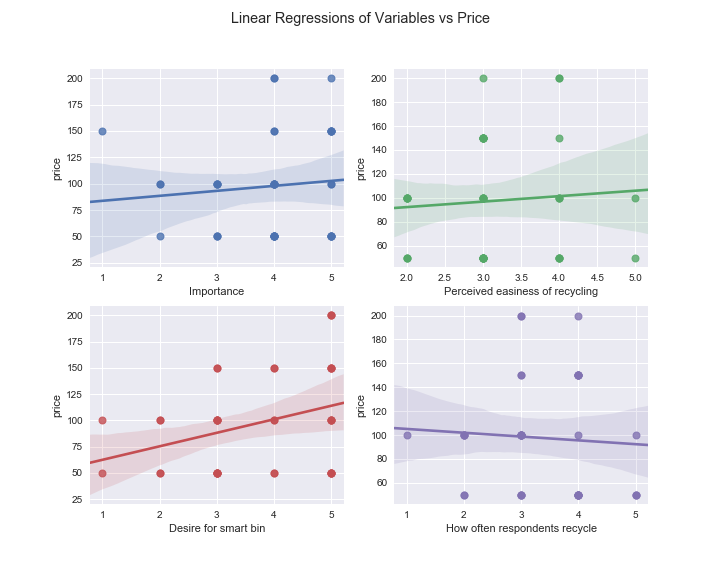

To further see if these correlations hold when asked how much respondents are willing to pay for the smart bin several linear regressions were preformed with the Seaborn library. The result is visible below:

As visible by the large confidence intervals and nearly horizontal regressions in all four cases no statistically significant correlation could be found.

A further attempt to categorize the data was to perform create a model using the k-nearest-neighbour clustering algorithm. Multiple models were set with a cluster size of 2, 3 and 4 and then fitted to the data. However in all cases the normalized mean square distance from the cluster centers to the attributed data entries was larger than 10 000, clearly showing that these models were unfit for our data-set and had no predictive value.

Survey 2

From our second survey, we found that more than half (65%) of people would like this Smart bin in their homes. From the people who didn't want this bin, the biggest reason was that they can do it themselves. Of all the people who said that they would like this product in their homes all of them said that they would recycle more if they had it. Mostly people would like to do as little maintenance as possible each week on the smart bin. It was also found that approximately 64% of people would prefer if this bin was completely self-cleaning, which makes this an aspect to look into more. The feedback that people prefer from our smart bin is with Lights(different LED's). From the survey it is clear that people want this bin to collect (in order of preference); plastic, organic waste, general waste, paper metals and glass. If this bin is widely used in all homes people would want all waste collected from their home, with the money saved at recycling companies hopefully this could become a possibility which could also potentially increase recycling.

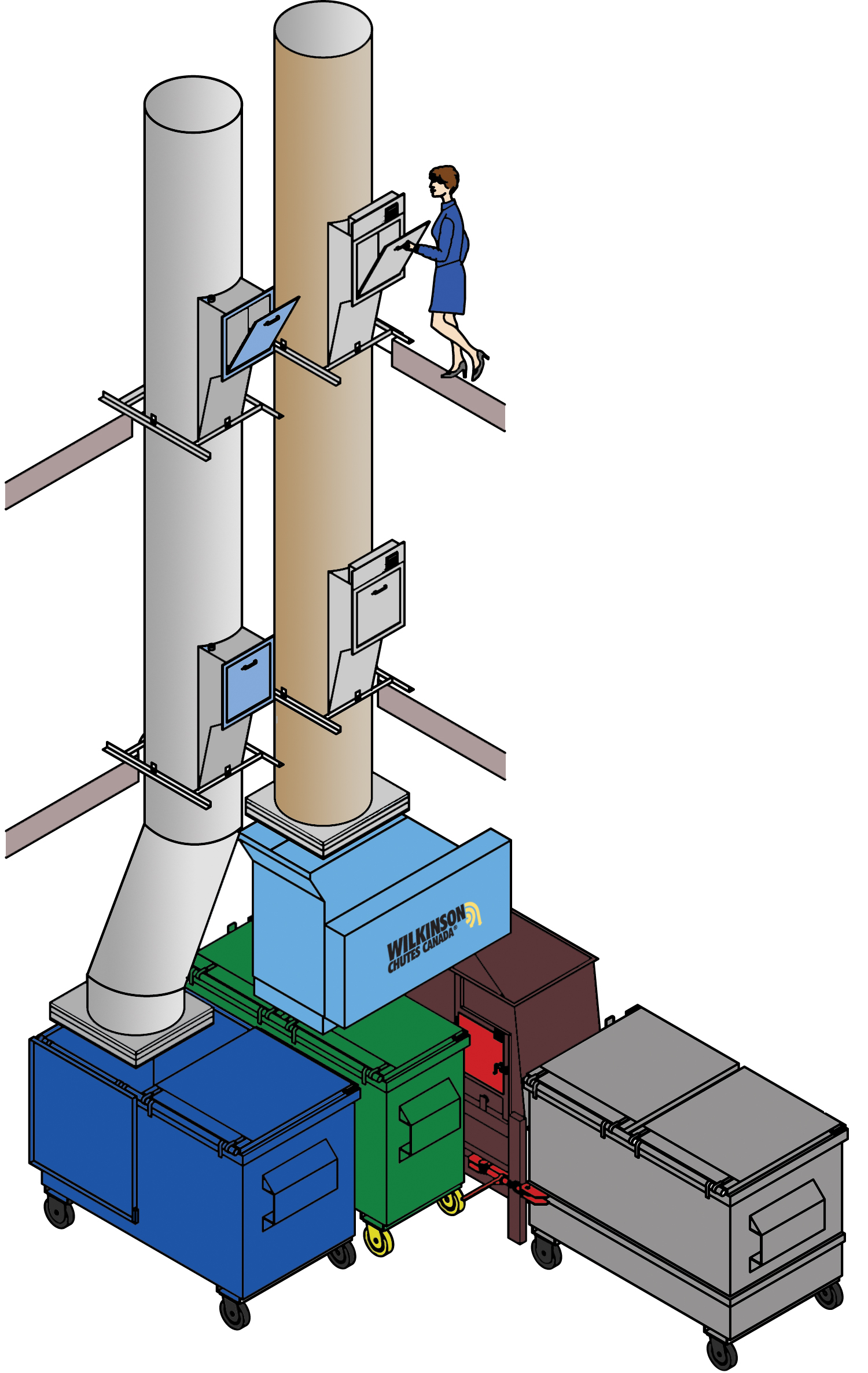

We also asked for the users opinion and got some very helpful suggestions. One of the suggestions is something we already thought about and that is making the bin on a larger scale for apartments. "Also I think for cities with lots of buildings and apartments, it's more efficient to implement the smart bin concept on a larger scale, like a disposal area per floor. This way it's also cheaper investment per person and hence, more people will use it." This is indeed something to investigate further especially if the smart bins do become a common household item. Implementing a shredder for the paper items to save space, is a possible new feature as from the first thoughts the advantages out weigh the disadvantages. "It has great use in Medical Waste in hospitals and healthcare facilities for disposables/single use items. I can provide guidance." was said by one of our participants and from this it could be a good idea to look into for future improvements to have a customizable bin. Someone also said they would like it if the bin reminded them which days certain recyclables are collected to help them clear the bin more efficiently.

Development

Hazards

This part has been merged into Product specifications.

Product specifications

The principle is that, the smart bin should not be made to detect everything, but aim to help users distinguish wastes that seem recyclable while actually are not, such as contaminated plastic, photos and milk boxes. The detailed requirements can be found in this file: Requirements

Size

51.2% of responses in the survey claimed the desired size of the bin is 30 litres, and the same percentage have chosen 50 litres (there were more options and therefore the percentage does not add up to 100%). This is a clear preference since about 19.6% of the responses include other sizes: around 5% would choose a smaller size of 10l which is not feasible for our design. The trend is explainable, the most preferred sizes usually feature in the main trash can of the household, usually placed in the kitchen where most mixed waste is disposed of. The result complies with our vision perfectly since that main bin of the household, exchanged with a smart bin would make the most impact on the recycled quantities.

Number of baskets

Since there is limited space in the trash bin, it was decided that certain categories do not need to be recycled by the device, but it would be more effective if they are recycled directly by the user. For example, cardboard is usually very voluminous and easy to categorise; for this reason, it would be more space-efficient if it was not included in the smart bin categories. The survey has shown that 100% of people who responded already recycle it and this is for good reasons: it is easy to save, it is made of light material and most importantly, it already gets collected every 2 weeks (In the Netherlands). In case of glass, only 65.9% of our sample recycle it and this can be due to the fact that glass is a heavy material which must be transported to the collection points: since it is easy to categories in the three types (white, brown and green glass) and is also voluminous, the better solution than a smart bin can be more collection points in the city, which will facilitate the transportation of glass from the house to the designated bins and make use of the willingness of people to recycle it. Electronic, clothes and chemical waste will be left out since there are hazardous materials and must be dealt with carefully (for instance, simply puncturing a battery can cause a fire). This waste is rare and the risk of fire or contamination is too high in case of electronics and chemical waste. About clothes, not that many people recycle them, the numbers show 31%. This might be due to the lack of collection points which are usually in stores. Sometimes clothes are thrown away in waste because they cannot be donated (they have holes or the material is ripped) and people do keep clothing for longer periods. A solution to this is public awareness: as long as people know the need to recycle these categories and know which stores accept them, then the percentage might change on its own. For now, it is not of maximum utility to use the space of a smart bin for rare waste.

Sketching

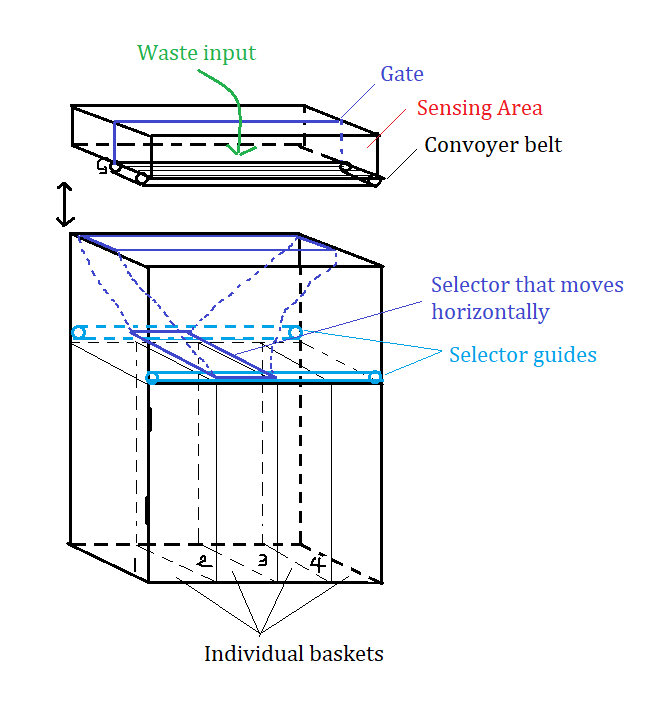

The sketching version 2.0 is shown below.

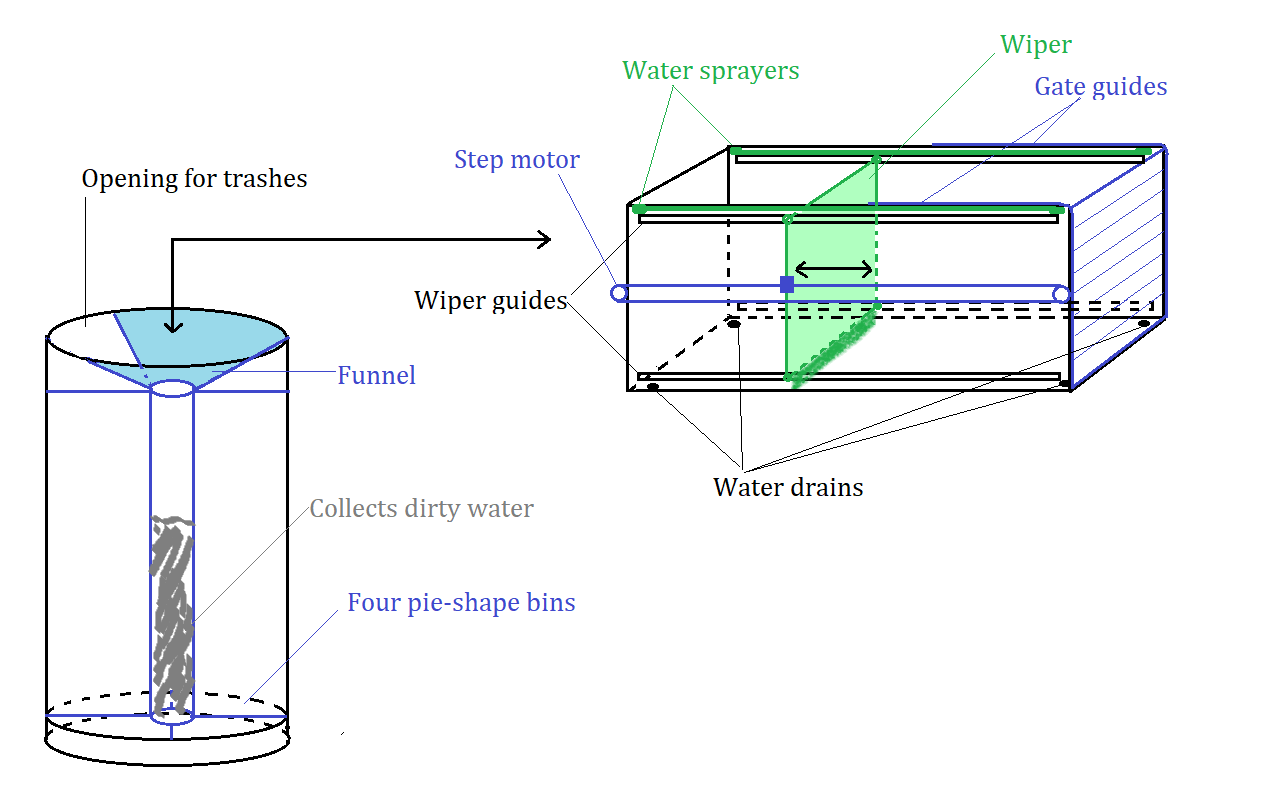

A sketch of the new design version 3.0 is shown below. The difference of this design is that, although version 3.0 has more complicated mechanical structure, it is easier to achieve self-cleaning.

Cleanboy 3.0

A description of model Cleanboy 3.0 can be better explained with the procedural steps that happen when an item is thrown in the smart bin:

- Throw the item into the bin.

- Cover the opening with the sliding inner walls.

- Scan the trash object.

- Once the object is detected, select the correct trash container for its category and start moving the containers.

- Start pushing the item with the wiper until it reaches the end of the box.

- The item will fall in the container.

- Move back the moving walls and wiper.

- Sense if any object is stuck in the funnel.

- After the process is finished, check the queue first for automatic cleaning, then for another item. If no cleaning is requested, repeat all steps from 2-9 if another object is detected. Otherwise, continue with step 10.

- Water sprayers receive water from the tap and they spray it across the bottom of the box.

- The wiper moves between the two sides to clean, the wiper has brushes at the bottom (no rubber required).

- The water supply stops in about t1 minutes.

- After the water supply stops, the wiper still needs to brush the remaining water away for a few more minutes (t2).

- The water drains down the funnel. Then the residual water needs to be emptied by the user.

Side notes:

- The funnel collects the dirty water which can carry larger objects (for example seeds), therefore the disposed water should first be filtered of these large residues. This can be done by placing a strainer on top of the tube of the funnel.

- Time t1 and t2 can be found empirically.

- Step 14 can be improved: instead of emptying the water, a drain can simply be connected to the lowest pipe system, just like the shower. Moreover, the valve to the sewing system does not have to open all the time, but it can be released only when enough water has gathered so only when a certain level in the reservoir was reached. The release system can be controlled in various ways, but they are all subjected to flaws:

- humidity sensor: the sensor would say when it is wet or not. If there is water on the pipe/tube, then the sensor would output 1, but this can happen also after the water has been released since the sensor will still be wet (it takes time to dry).

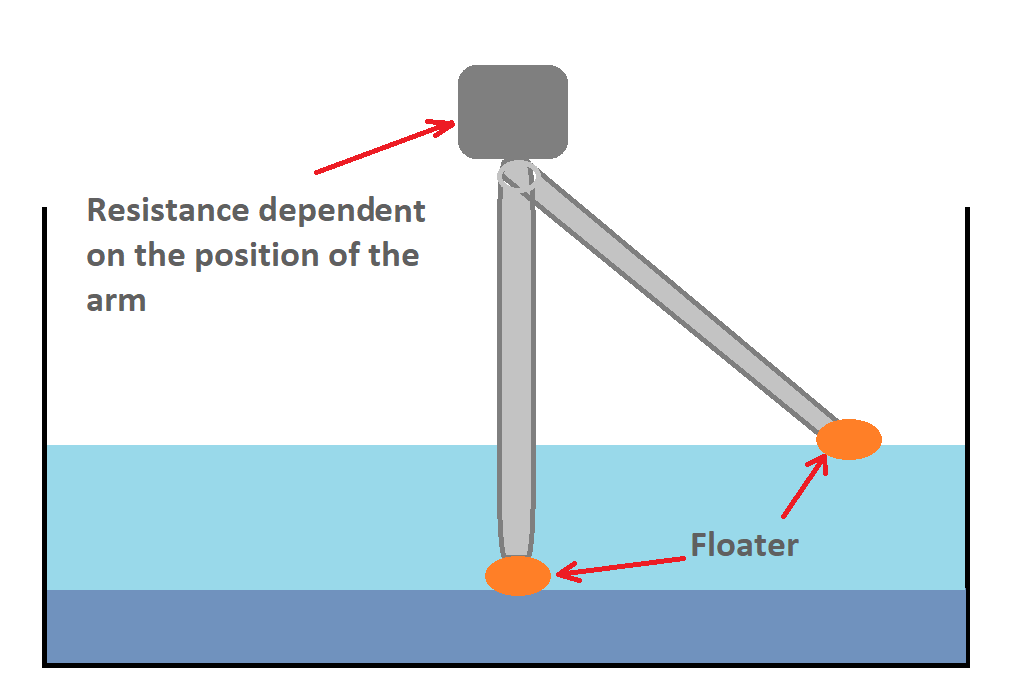

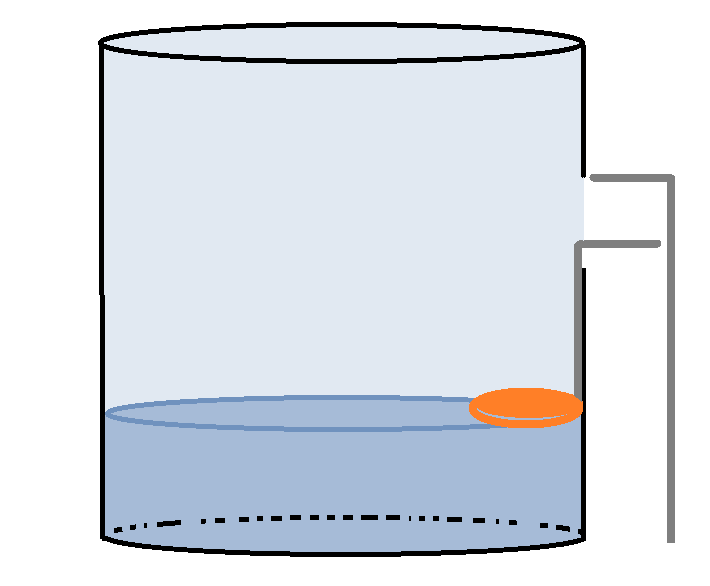

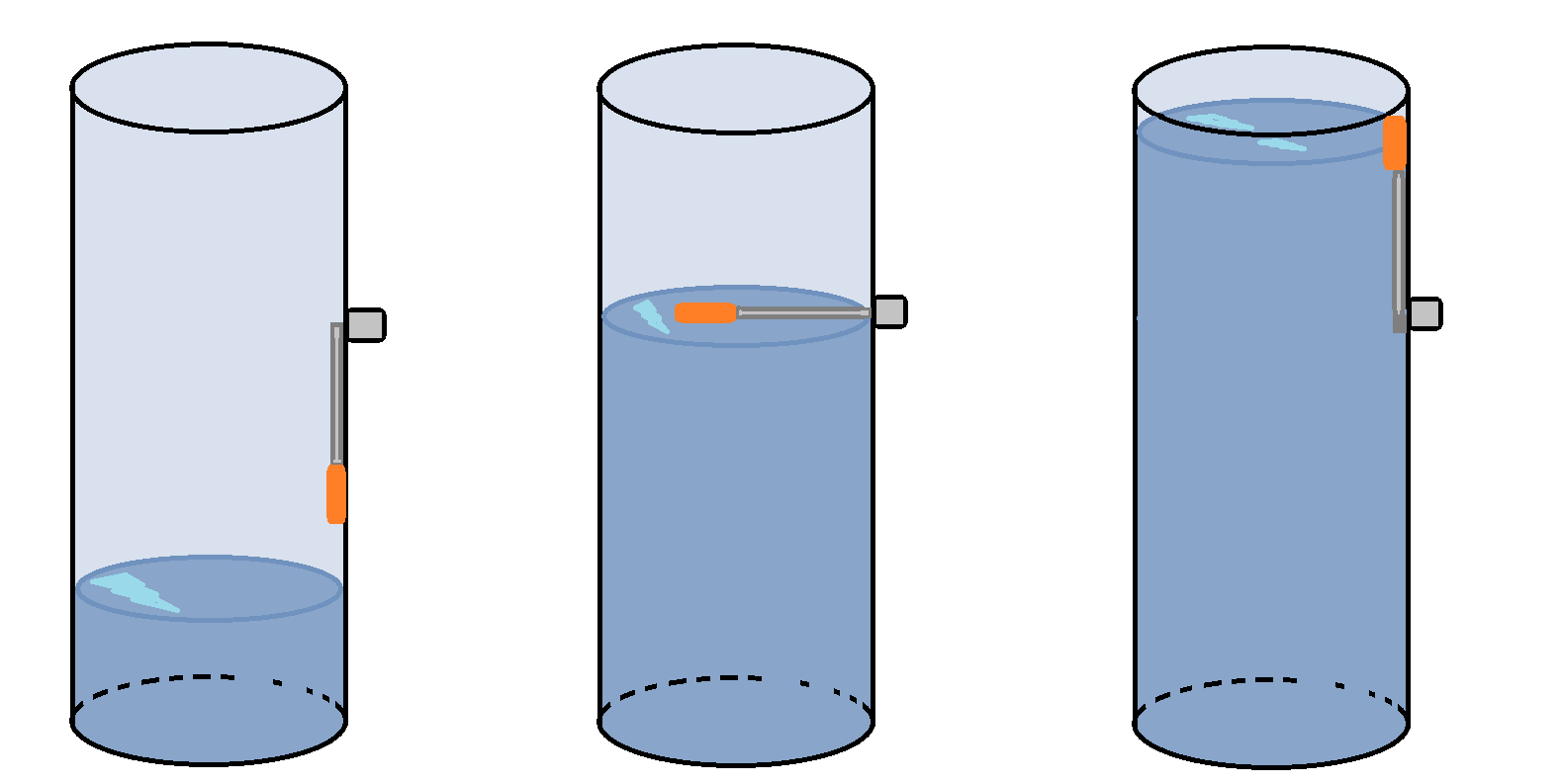

- floater; One idea to detect the water level is with a floater, like the level of fuel in the tank of a car is detected. As the level rises, the resistance seen by the gauge changes. This is illustrated in the image below.

The same idea can be applied to the water tube:

Unfortunately, this method is not reliable due to two reasons. Firstly, if the water level rises very quickly, the middle stage might not be observed and the first and third ones are the same. Secondly, the mechanism might not be as reliable on a small scale as on a normal scale (size used in cars).

- camera; another idea would be to use a camera and a red ball in the tunnel. In this way, the camera should observe when the red point gets closer, but cameras are expensive and in this case, there is no light so an additional light is a must. These seem that would bring more flaws than simple solutions compared to ideas mentioned above.

- switch: as the water level rises, the contact would be brought to the right place as in the below image below:

Unfortunately, this can cause a more severe problem if the water level rises too fast: leakage can occur in the circuitry. To solve the problem of the gap, one can place a rubber instead of the gap in the wall and replace the metal part of the switch with a lever. The lever touches the metal part outside the tube and as the water rises, the right half of the lever is pulled down and the contact is detached.

- water tank: the idea used in the fuel gauge for cars would work on a larger scale, which could happen in this design as well if a water tank is added under the containers, at the very bottom. Therefore the residual water can be discharged when the tank is full and during this time the cleaning process can stop.

Bonus points of the design:

- The sliding door that moves over the scanning cavity ensures darkness for the scanner and offers protection for the user from the light, which can be harmful when exposed to it multiple times.

Drawbacks:

- Using a strainer to block the larger object would help to keep the tunnel unblock. If this happened, it would result in a huge problem since the tube of the funnel should be narrow. If the tunnel was large, then it would take too much space that could instead be used as extra volume for the trash containers. Therefore as the tunnel is narrow, if any object was stuck in there, unblocking it would become a very difficult task even with user intervention (the stuck object should be pulled up or pushed down the tunnel after taking apart the bottom and reaching it would also be difficult). The strainer plays an important role, but it creates another flaw. The water only goes through the funnel and then it is directly pumped out to the drain system. If the flux of water is high and the pump is not fast enough or the canal gets blocked somehow (maybe residue on the walls of the tube) or if the large objects that were stopped at the strainer would lade the flow of water, then there might be more and more water gathering on top of the strainer; when there is too much water that cannot flow through, it will reach the level of the gap on the side of the funnel (through which trash falls through) and pour into the container.

- The device should be as compact as possible, and this requirement is not fully satisfied since the control box (that contains the scanner) is above the funnel and space between the two does not serve as any purpose.

- After the scanning, the control sends the decision in what mode all trash containers should rotate so that the right one is below the gap of the funnel. That means that after each item is thrown in the trash, more and more energy is used to move the larger mass of trash. This seems impractical since more energy is used for this than just rotating the funnel or the control box each time. On the other hand, the mechanism that would move the trash containers might be more robust than rotating the control box (there will be many wires and the control box should stay stable since it is the connection with the "outer world") or the funnel (the funnel would rotate on the same principle as the containers since they both have circular shapes, but the rail of the funnel has more chances of getting dirty and therefore fail due to some blockage).

- The funnel itself and the edges of the funnel and of the floor of the box will never be really clean. In order to make the bin sparkling, the user will always need to do it themselves.

- Moving all the containers can raise another problem: loose of balance. In order to ensure fast functioning of the sorting process, the rotation must be fast. In the worst case, only one of the containers will be completely full and rotating it with high speed might give it a large momentum and a high centrifugal force; the latter could cause the object to move and be noisy (like a washing machine in the drying mode). Unfortunately, this scenario can easily happen after throwing just some of the trash bags away (because it is collection day for example).

- Automatic cleaning means the

- Time of the self-cleaning might really depend on the type of trash thrown in. For example, biological trash will cause more residue than plastics. Some people use fresh vegetables when preparing food, others use pre-cut produces and therefore make less mess. Ideally, the users should be able to start and stop the process whenever they want. Unfortunately, this implies that the user has to see the surfaces inside and this can be done by using transparent plastic as a case for the mechanism. If the case of the trash was transparent, it would look inesthetic and this would not protect the user from the infrared light.

- Since the design features 4 water strains, there is no point in having the tube of the funnel in the middle of the containers, which makes the system more prone to faults; the residual water can as well be redirected to the side with no other consequences.

Paper prototype

Step-by-step construction guide

The group decided to focus only on the validation of the construction of the sorting box. Due to all kinds of limitations, the validation could only be carried out by providing a step-by-step construction guide and with animation presentation.

General

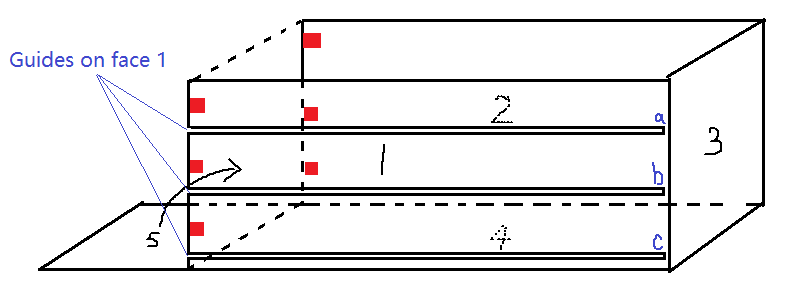

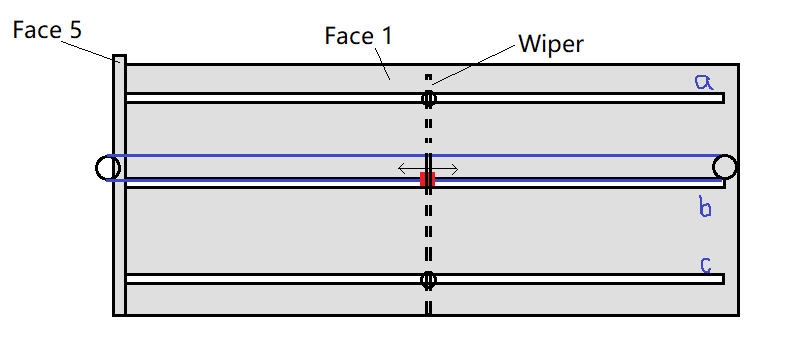

In order to make the description easier, some simple sketches are made along with the texts. Firstly, the box is divided into 5 faces, which are called from 1 to 5, indicated in the figure below

Face 1, 2, 4 will be made as a whole. Face 3 is the gate, which will be discussed individually. Face 5 can fold or be disassembled. In the beginning it is open so that the wiper can be mounted to the guides on face 1 and 2. The wiper will also be introduced in an individual section. After the wiper and water tubes are mounted, face 5 can be attached to the box by using right-angle connectors like the one shown below.

Such connectors are mounted at the red positions indicated in Figure 1. This will compensate for the deduction in structural strength caused by the guides. The corresponding holes are drilled on face 5. If face 5 is decided to be able to be completely disassembled, such connectors will be put on face 4 as well.

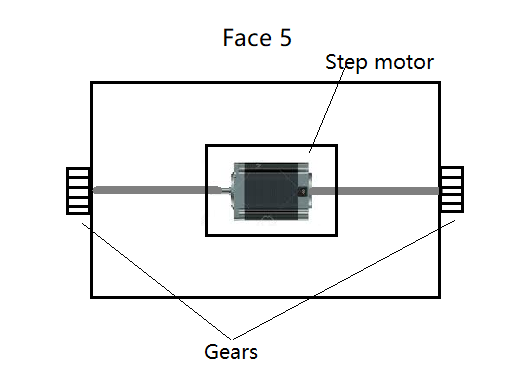

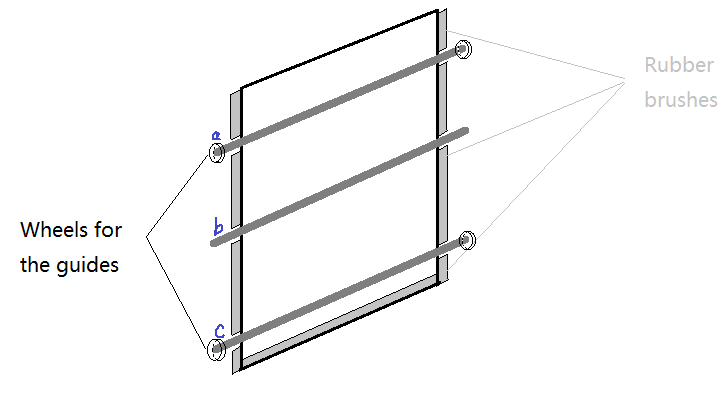

On the outer side of face 5, a step motor is mounted, whose transmission shaft is connected to a pair of gears. A schematic is shown in the figure below.

Another pair of such gears are mounted respectively on face 1 and 2, at same vertical position above guide (b). A pair of gear drive belts connects those two pairs of gears. Two cubes with hole are fixed to the sides of the belts which are horizontally parallel to guide (b). The sticks on the wiper are plugged into the wholes of the cubes so that when the step motor spins, the gears carry the belts and the wiper moves back and forth. The reason for using stepper motor instead of normal motor is that, it can be controlled precisely when to stop and when to start, without pushing the wiper into face 1 or 5.

By determine the length of the guides, the angular step width of the motor and the radius of the gears, the steps needed for the wiper to move from one side to the other can be calculated.

Wiper

The wiper is basically a plate with rubber brushes, like rain wiper on the cars, at its edges. An alternative is to use brushes, since rain wiper always need water to work properly. A schematic is given:

The wiper will be put into the corresponding guides before face 5 is closed. Whenever the wiper itself needs to be replaced or cleaned, face 5 can be dismounted and the old wiper can be taken out.

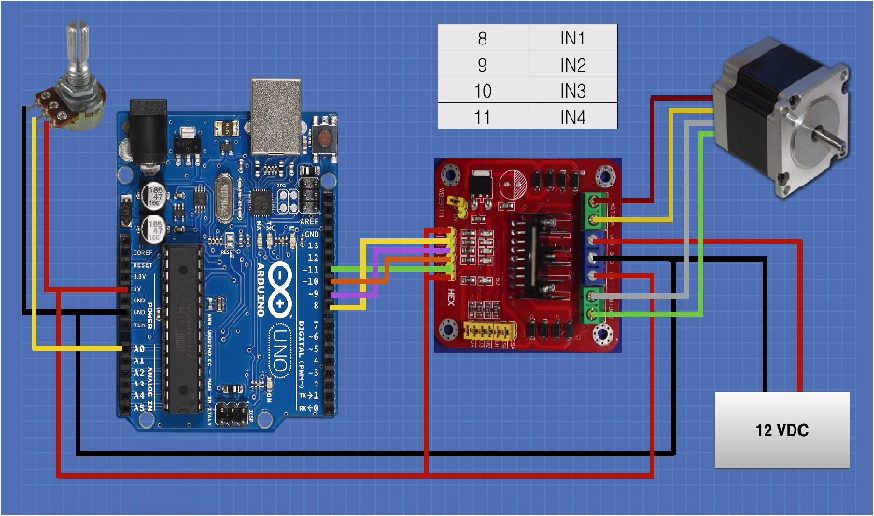

Stepper Motor

Limited by the scope of this project and considering the availability of the components, it is decided to use NEMA 17 17HS8401 Bipolar stepper motor (More data on this site), L298N motor driver, and Arduino as controller. It is decided to use a bipolar stepper motor because bipolar motors have stronger torque than unipolar ones.

This motor can provide a torque up to 5 kg·cm [64]. The radius of the gears on face 5 is 2 cm. Assume that the friction between the wiper and the box can be up to 0.5 kg, the force that pushes the trash can still be up to 2 kg. In a conservative estimation, the friction coefficient between the trash and the bottom of the box (plastic) can be 0.5 [65], if smoother material like Teflon is used, it can be even lower. This gives a maximum trash weight of 4 kg. In the user surveys of this project, most people would like paper, plastic, glass and organic waste recycled. It is notable that this structure is designed for household, and common trashes are empty bottles, boxes and small pieces of waste food, which are assumed in this project not to be heavier than 4 kg.

The angular speed ω of the motor can be up to 4688 RPM [66], depending on the load. Assuming the motor is designed to work at 120 RPS, which is 2 rev/s, given that the radius r of the gears is 2 cm, the linear speed of the wiper can be calculated as:

v = r·ω = 12.56 cm/s.

The box is 30cm in length, which means the time needed for the wiper to move back and forth is 2.3 x 2 = 4.6 seconds. This satisfies the requirement that "Time to identify and sort waste < 5s". Due to the situation of Corona Virus, it is not possible to test with the components. In case faster or stronger motor is needed, different motor driver will be needed, which exceeds the focus of the group.

The connection of the components is shown in the figure below. It is taken from a YouTube video [67], but it shows the exaction connection clearly and is good enough for a validation.

In this design, the potentiometer is not necessary. The ".Setspeed" function in Arduino can automatically translate the desired motor speed to digital inputs to the driver, and the driver will make the motor spin.

Sensor

The emitter is mounted on the top cover, and the receiver is mounted on face 4. When the user opens the top cover and throw trash in the container, gate on face 3 is closed. When the top cover is closed, it seals the whole box and starts the sensing process. When the sensing is done, the gate opens and the wiper pushes the trash away.

References

- ↑ 1.0 1.1 Ilene J. Bush-Vishniac, Eletromechanical Sensors and Actuators, Date accesed: 2020-02-09 www.parker.com › LPCE › function-fittings .

- ↑ 2.0 2.1 Pneumatic Sensor fittings Datasheet, (Springer, 1999).

- ↑ 3.0 3.1 Y Shigeta, S Hayano, Y Saito, Magnetic sensor signal Analysis, (International Journal of Electromagnetics and Mechanics, 2001/2002).

- ↑ 5 reasons to choose Induction over Hall Effect sensors, Date accesed: 2020-02-09 https://www.gillsc.com/newsitem/45/5-reasons-choose-induction-over-hall-effect-sensors.

- ↑ 5.0 5.1 Darran Kreit, Inductive verses Capacitive sensors, (Elsevier, 2013).

- ↑ 6.0 6.1 K Nakamura, Ultrasonic transducers : materials and design for sensors, actuators and medical applications, Part 3,

- ↑ 7.0 7.1 7.2 7.3 Sharma, N., Singha, N., & Dutta, T. (2015). "Smart Bin Implementation for Smart Cities". http://www.ijser.org. 5. Published: International Journal of Scientific & Engineering Research, 6(9).Date accessed: 2020-02-08.

- ↑ 8.0 8.1 Thomas, C., Slater, R., Leaman, J., & Downing, P. (n.d.)." What Makes People Recycle? An Evaluation of Attitudes and Behaviour in London Western Riverside. 11. Date accessed: 2020-02-09.

- ↑ 9.0 9.1 Roberts, F. (2017)."Smart bin from Polish start-up Bin-e set to sort UK recycling problems.https://internetofbusiness.com/smart-bin-bin-e-recycling/. Date accessed: 2020-02-05.

- ↑ 10.0 10.1 Ramson, S. R. J., & Moni, D. J. (2017)." Wireless sensor networks based smart bin.https://doi.org/10.1016/j.compeleceng.2016.11.030. 17: 337-353. Date accessed: 2020-02-08.

- ↑ 11.0 11.1 Peco-InspX. Detecting Plastics with X-Ray Inspection Systems. Date accessed: 2020-02-05. https://www.peco-inspx.com/blog/x-ray-detectable-plastics/

- ↑ 12.0 12.1 Sol M. Gruner.(2012). "X-ray imaging detectors" https://physicstoday.scitation.org/doi/10.1063/PT.3.1819 Pulisher: American Institute of Physics. Date accessed: 2020-02-06

- ↑ 13.0 13.1 Mary E.Coles. (1999). "8. X-Ray Imaging". https://doi.org/10.1016/S0076-695X(08)60419-6 . 35: 301-336. Date accessed: 2020-02-08.

- ↑ 14.0 14.1 Schroer, Christian G. (2011). "X-ray imaging: The chemistry inside". Nature. 476: 159-160. https://www-nature-com.dianus.libr.tue.nl/articles/476159a Date accessed: 2020-02-06

- ↑ 15.0 15.1 Liu, Ying-Ho; Lee, Anthony J.T.; Chang, Fu. (2012). "Object recognition using discriminative parts". Computer Vision and Image Understanding. 116: 854-867.

- ↑ ,https://en.wikipedia.org/wiki/Recyc,ling_in_the_Netherlands , Recycling in the Netherlands, Date accessed: 2020-02-14.

- ↑ ,https://www.eindhoven.nl/en/city-and-living/living/waste-recycling, WASTE & RECYCLING, Date accessed: 2020-02-15.

- ↑ ,https://www.cure-afvalbeheer.nl/en , Cure Afvalbeheer, Date accessed: 2020-02-15.

- ↑ , Maarten Goorhuis, Pieter Reus, Ellen Nieuwenhuis, Natascha Spanbroek, Mario Sol, Jørgen van Rijn,(2012) https://journals.sagepub.com/doi/10.1177/0734242X12455089 , New developments in waste management in the Netherlands, Date accessed: 2020-02-15.

- ↑ ,https://wilkinsonchutes.ca/ , Wilkinson Chutes, Date accessed: 2020-02-20.

- ↑ Paulien de Jong, Maarten Wolsink "THE STRUCTURE OF THE DUTCH WASTE SECTOR AND IMPEDIMENTS FOR WASTE REDUCTION" Waste Management & Research (1997) 15, 641–658

- ↑ https://business.gov.nl/running-your-business/environmental-impact/waste/producer-responsibility/, Dutch government, Date accessed: 2020-02-19

- ↑ https://www.environmental-expert.com/waste-recycling/companies/location-netherlands, Environmental XPERT, Date accessed: 2020-02-20

- ↑ https://www.wastematters.eu/uploads/media/DWMA_wasteforum_Netherlands_imports_more_waste_sept_2011.pdf , Wastematters, Date accessed: 2020-02-21

- ↑ https://www.conserve-energy-future.com/recyclingmetal.php, Conserve energy future, Date accessed: 2020-02-19

- ↑ R.W.J. McKinney, "The Technology of paper recycling", Springer, 1997

- ↑ Chongrak Polprasert, "Organic Waste Recycling - Technology and Management", IWA Publishing, 2007

- ↑ Azeem Khalid, Muhammad Arshad, Muzammil Anjum, Tariq Mahmood, Lorna Dawson, "The anaerobic digestion of solid organic waste", Waste Management, Volume 31, Issue 8, 2011, Pages 1737-1744

- ↑ https://www.enfrecycling.com/directory/plastic-plant/Netherlands, ENF recycling, Date accessed: 2020-02-22

- ↑ https://www.milieucentraal.nl/minder-afval/afval-scheiden-cijfers-en-kilos/ , Milieucentraal, Date accessed: 2020-02-19

- ↑ Kaiser, K.; Schmid, M.; Schlummer, M. "Recycling of Polymer-Based Multilayer Packaging: A Review." Recycling 2018, 3, 1.

- ↑ D M Scott 1995 Meas. Sci. Technol. 6 156 ‘A two-colour near-infrared sensor for sorting recycled plastic waste’

- ↑ Iñigo Vegas, Kris Broos, Peter Nielsen, Oliver Lambertz, Amaia Lisbona, Upgrading the quality of mixed recycled aggregates from construction and demolition waste by using near-infrared sorting technology, Construction and Building Materials, Volume 75, 2015, Pages 121-128, ISSN 0950-0618, https://doi.org/10.1016/j.conbuildmat.2014.09.109.

- ↑ Offer Rozenstein, Eldon Puckrin, Jan Adamowski, Development of a new approach based on midwave infrared spectroscopy for post-consumer black plastic waste sorting in the recycling industry, Waste Management, Volume 68, 2017, Pages 38-44, ISSN 0956-053X, https://doi.org/10.1016/j.wasman.2017.07.023.

- ↑ A. C. Karaca, A. Ertürk, M. K. Güllü, M. Elmas and S. Ertürk, "Automatic waste sorting using shortwave infrared hyperspectral imaging system," 2013 5th Workshop on Hyperspectral Image and Signal Processing: Evolution in Remote Sensing (WHISPERS), Gainesville, FL, 2013, pp. 1-4. doi: 10.1109/WHISPERS.2013.8080744

- ↑ Masanori Kumagai, Hideto Suyama, Tomoaki Sato, Toshio Amano, and Nobuaki Ogawa, "Discrimination of Plastics Using a Portable near Infrared Spectrometer," J. Near Infrared Spectrosc. 10, 247-255 (2002)

- ↑ https://www.sigmaaldrich.com/technical-documents/articles/biology/ir-spectrum-table.html#ir-spectrum-table-by-range , Spectroscopy table from Sigma Aldrich, Accessed on 09-03-2020

- ↑ Wong, J. & Gan, Seng Neon & Aishah, M.. (2011). Chromium(III) Based Ziegler-Natta Catalysts for Olefin Polymerization. Sains Malaysiana. 40. 771-779.

- ↑ http://www.nicodom.cz/ , NICODOM, library version from 02-2020

- ↑ https://spectrabase.com/ , Spectra Base, accessed on 10-03-2020

- ↑ https://sdbs.db.aist.go.jp/ , Specrtal Database from the AIST, accessed on 10-03-2020

- ↑ 42.0 42.1 L. Stoch and M. Środa, “Infrared spectroscopy in the investigation of oxide glasses structure,” J. Mol. Struct., vol. 511–512, pp. 77–84, 1999.

- ↑ J. Skvaril, K. Kyprianidis, A. Avelin, M. Odlare, and E. Dahlquist, “Utilization of Near Infrared (NIR) Spectrometry for Detection of Glass in the Waste-based Fuel,” Energy Procedia, vol. 75, pp. 734–741, 2015.

- ↑ A. Agarwal and M. Tomozawa, “Correlation of silica glass properties with the infrared spectra,” J. Non. Cryst. Solids, vol. 209, no. 1–2, pp. 166–174, 1997.

- ↑ 45.0 45.1 V. Causin, C. Marega, A. Marigo, R. Casamassima, G. Peluso, and L. Ripani, “Forensic differentiation of paper by X-ray diffraction and infrared spectroscopy,” Forensic Sci. Int., vol. 197, no. 1–3, pp. 70–74, 2010.

- ↑ D. M. C. Ruiz-Carcel, Y. Cao, “Identify paper finishes using infrared spectroscopy,” vol. 61, no. 4, pp. 1029–1036, 2012.

- ↑ C. Kittel, Introduction to Solid State Physics, vol. 8, no. 9. 1957.

- ↑ 48.0 48.1 M. Osawa, K. I. Ataka, K. Yoshii, and Y. Nishikawa, “Surface-enhanced infrared spectroscopy: The origin of the absorption enhancement and band selection rule in the infrared spectra of molecules adsorbed on fine metal particles,” Appl. Spectrosc., vol. 47, no. 9, pp. 1497–1502, 1993.

- ↑ T. R. Jensen, R. P. Van Duyne, S. A. Johnson, and V. A. Maroni, “Surface-enhanced infrared spectroscopy: A comparison of metal island films with discrete and nondiscrete surface plasmons,” Appl. Spectrosc., vol. 54, no. 3, pp. 371–377, 2000.

- ↑ 50.0 50.1 50.2 50.3 A. Peterson, “Towards Recycling of Textile Fibers,” 2015.

- ↑ R. Cook and M. D. Paterson, “New techniques for the identification of microscopic samples of textile fibres by infrared spectroscopy,” Forensic Sci. Int., vol. 12, no. 3, pp. 237–243, 1978.

- ↑ A. Allen, J. Foulk, and G. Gamble, “Preliminary Fourier-transform infrared spectroscopy analysis of cotton trash,” J. Cotton Sci., vol. 11, no. 1, pp. 68–74, 2007.

- ↑ W. H. Su and D. W. Sun, “Mid-infrared (MIR) Spectroscopy for Quality Analysis of Liquid Foods,” Food Eng. Rev., vol. 11, no. 3, pp. 142–158, 2019.

- ↑ L. L. Fialho, W. T. L. da Silva, D. M. B. P. Milori, M. L. Simões, and L. Martin-Neto, “Characterization of organic matter from composting of different residues by physicochemical and spectroscopic methods,” Bioresour. Technol., vol. 101, no. 6, pp. 1927–1934, 2010.

- ↑ 55.0 55.1 E. Smidt, P. Lechner, M. Schwanninger, G. Haberhauer, and M. H. Gerzabek, “Characterization of waste organic matter by FT-IR spectroscopy: Application in waste science,” Appl. Spectrosc., vol. 56, no. 9, pp. 1170–1175, 2002.

- ↑ 56.0 56.1 E. Smidt and K. Meissl, “The applicability of Fourier transform infrared (FT-IR) spectroscopy in waste management,” Waste Manag., vol. 27, no. 2, pp. 268–276, 2007.

- ↑ N. Rohe and T. Eisenreich, “Infrared Spectroscopy in Analysis of Plastics Recycling,” Encycl. Anal. Chem. Appl. Theory Instrum., 2006.

- ↑ 58.0 58.1 B. Luijsterburg and H. Goossens, “Assessment of plastic packaging waste: Material origin, methods, properties,” Resour. Conserv. Recycl., vol. 85, pp. 88–97, 2014.