PRE2019 3 Group20

Group members

| Name | Student ID | Program |

|---|---|---|

| Erik Heijerman | 1298968 | Industrial Design |

| Wouter Meeuwis | 1338390 | Industrial Design |

| Kevin Pits | 0896637 | Software Science |

| Teun Schutten | 1333607 | Industrial Design |

Problem statement and objectives

As summer approaches and it gets hotter in the Netherlands, yearly millions of people flock to the Dutch beaches to cool down, get a tan and escape the bustle of the city. this is not only a popular activity for locals, but also for millions of tourists who visit the Netherlands every year. The beach at Scheveningen, one of the most popular beaches in the Netherlands, already welcomes 17 million visitors annually[1].

This big source of tourism boosts the local economy, but also has its downsides. Because more often than not there are too few trash cans on the beaches, and people generally cannot be bothered to take their trash with them, beaches get littered. Lots of plastic packaging, glass bottles, aluminum cans and other waste ends up in the sand, most of which does not decompose. Plastic waste in particular is a major problem on the beaches. Larger pieces of plastic break up into micro plastics. These micro plastics end up in nature and are expected to be very harmful to wildlife, sea life and other nature.

There have been some local initiatives to clean up litter on the beaches. An example of this is a yearly 95 day clean up action at the beach of Scheveningen, that this year resulted in 3100 kilos of collected trash[1]. However, the entire problem cannot be solved by these local initiatives only. Having people picking up litter is very time consuming, inefficient and it requires a lot people to properly do it. On top of this, because of bad labor circumstances it almost always has to be done by volunteers.

In this project, we want to develop a robot which is able to autonomously collect plastics on beaches in an efficient, strategic and sustainable way to counter the plastic waste which breaks up into micro plastics. We will mainly focus on the robot's grabbing system. The robot is first and foremost aimed to be more efficient than its human counterparts by using innovative techniques to pick up litter and by working more continuously. Another objective is that the robot has to function in a sustainable way by using renewable energy.

Users

Our users are the RVB and the city councils of municipalities which border a coast.

In the Netherlands, the beach from the sea to the dune foot is property of the Rijksvastgoedbedrijf (RVB). The Rijksvastgoedbedrijf is the real estate organization of the Dutch government. The RVB is responsible for the management and maintenance of real estate in use by the Dutch state. This means that for the Dutch beaches, the Rijksvastgoedbedrijf together with the city council of the city where the beach is located are responsible for maintaining and taking care of these beaches. Because they are both responsible for this task, they will also be the users of the robot.

In this project we lay a more specific focus on the beach of Scheveningen, as this is a familiar environment, has great tourism and are easily approachable. The people that are most responsible for this beach are boulevardmanagers Eite Levinga and Peggy ten Hoopen. We urge to contact them as they can provide us with more experience and expertise about the most common kind of litter and about their current techniques for litter-removal.

The goals of the users (the city councils) are as followed:

- The users aim to preserve the environment by minimizing the amount of litter and trash on the beaches as well as avoiding or decreasing sea pollution. Protecting plants and wildlife on land as well as sealife plays a big role in this motivation.

- The users aim to preserve cleaner beaches to satisfy tourists and local visitors, which will positively influence the appeal of the area. Preserving this reputation is an important factor to boost the local economy.

In order to achieve these goals, the robot is required to have certain abilities and features.

The robot will replace the job of a group of humans. To make this transition into robot labor profitable for the users, the job needs to be done more efficiently in terms of time and it has to be financially beneficial in the long run. In order to achieve this, the robot needs to work autonomously. If a lot of time is required of employees to use of the robot, it still requires some human labor with a salary, and therefore it is also limited to the skill and attention of the operator, making it more expensive and inconvenient. If the robot requires a lot of maintenance (both routine/preventative and emergency), it will be quite expensive and less reliable. Therefore, the robot needs to be low maintenance, with easy routine maintenance to prevent a total breakdown with costly repairs and downtime.

As beaches can be kilometers long, cleaning them will take a fair amount of time. To make this as efficient as possible, the robot is required to have a big long-lasting battery. To avoid an inefficient Roomba-like concept, the robot is required to have a detection system which can identify litter from the sand. The robot will have to store the litter as it moves on. To support the efficiency, the size of this storage is desired to be big. As the robot is required to move around on uncertain terrain like sand, meaning no flat surface, the robot has to be equipped with a mobility system that is able to overcome obstacles and rough terrain.

Stakeholders

In addition to the users of the robot, there are various other stakeholders who are of great importance. One of these stakeholders are the visitors of the beaches. After all, these visitors benefit from a clean, litter free beach on their day off.

The littering by the visitors of the beaches has a major negative effect on wildlife on land as well as in the sea. The natural habitat of the wildlife is seriously disturbed by the litter. In addition, many animals die from consuming plastic which is left behind on beaches. The robot is of great importance for maintaining a healthy natural habitat for the wildlife. This is the reason that wildlife on land and in the sea is seen as an important stakeholder.

State of the Art

Similar projects

Solarino[2]

Solarino is a remote-controlled beach cleaning robot which is developed by the Italian company DronyX. The developers claim it is “the first ecofriendly, remote-controlled beach cleaning machine able to move both on wet and dry sandy terrain and to remove rubbish and other foreign matter” (DronyX, 2017). This robot distinguishes itself from other beach cleaning robots by its focus on eco-friendliness and robustness.

Solarino is fully electrically driven, using isolated GEL batteries that are supported by solar panels mounted on top of the robot. Although these solar panels provide a substantial amount of the energy needed, the robot still needs to charge after every three hours of work. However, using a fully electrical drivetrain avoids using internal combustion engines or hydraulic systems, and makes it work silently. This all makes it a very eco-friendly robot.

Another point of focus of this robot is its robustness. It is built using both stainless steel and aluminum, making it very sturdy. The robot moves on wide rubber tracks which enables it to have good grip both on wet and dry sandy terrains. This makes it very mobile on the beach. It is furthermore designed to be wide with a low center of gravity, making it almost impossible to tip over. Because of its high-torque engine, Solarino also has the ability to tow heavy loads, like small boats or trailers.

Solarino uses a vibrating mechanical sifter to filter out litter from the sand. It scoops up the top layer of the sand and then sifts it such that only the sand falls through. A disadvantage of this technique is that rocks and shells also will be filtered from the beach.

All in all we can conclude that Solarino is a very well designed beach cleaning robot, with its strong points being its eco-friendliness, robustness and efficiency. However, where it falls short is that it is still remote-controlled and thus does not move around autonomously. Next to this is the fact that it has to charge after every 3 hours of working time and that it also removes rocks and shells from the beach. These weak points are something we can focus on in our project.

Thailand’s Robotic Trash Collector[3]

This robot is the result of a collaboration between the Thai petroleum company PTTEP and Prince of Songkla University’s Faculty of Engineering. The robot is very similar to Solarino, but has some noticeable advantages and disadvantages.

The main similarity between this robot and Solarino (as described above), is the technique that is used to filter out litter from the sand. Just as Solarino, this robot too uses a vibrating mechanical sifter. This technique is effective and quick, which was also the argument of the developers to implement the technique. However, a disadvantage of this technique is that rocks and shells also will be filtered from the beach.

This “home-grown robot” is different from Solarino in the fact that it does not work on solar power. Instead, it uses only rechargeable batteries. The eco-friendliness of this robot (in relation to Solarino) thus depends on how these batteries are charged.

This robot has two main strong points. The first is its compact design. Because of its small size, it is able to collect litter around trees in wooded areas. This is important because it previously could not be done by tractor-pulled beach cleaners. The second strong point of this robot is that it can be built locally. This saves a lot of importing costs and boosts local employment, which is especially important for a country like Thailand.

RF Controlled Beach Cleaner Robotic Vehicle[4]

The following robot has been developed by the Indian based Nevon Projects in 2019. Similar as the robots mentioned above, this robot has the purpose of picking up litter from beaches in an effective and eco-friendly way. Just as the Thai robot described earlier, this robot is a local initiative to fight pollution on beaches. However, this beach cleaning robot distinguishes itself from other examples by its shape, size, use of technique and simplicity.

First of all, the most noticeable difference between this robot and other examples like Solarino, is its shape and size. The Indian robot is much smaller and simpler. Where the other two robots had an elaborate internal system, frame and casing, this robot looks more low fidelity and straightforward. It does not have a very complicated structure, and all working parts are visible because of the lack of casing. All in all, this robot looks very simplistic. This is not a bad thing, because it makes the robot easy to mass-produce and assemble.

Secondly, another noticeable difference is that this robot moves around on big wheels instead of tracks. These wheels are driven by two high performance, high efficiency electrical motors and one electrical motor drives the cleaning mechanism. How these electrical motors are powered is not addressed. The robot can be remote-controlled by a radio frequency based remote control, but its built-in handlebars indicate that it can also be pushed manually.

Lastly, the robot uses a remarkable technique to pick up litter from the sand. Instead of using a vibrating mechanical sifter, which has its disadvantages, it uses a series of big metal hooks that are attached to a chain and sprocket system, powered by an electromotor. This creates a kind of conveyor-belt with hooks that constantly picks up litter, lifts it up to the top of the robot and then drops it in a replaceable garbage bag. This technique is very different from the ones we have encountered so far, and it can be a source of inspiration when we have to come up with our own cleaning mechanism.

Navigation

An autonomous beach cleaning robot has of course already been developed. This robot was unable to ride on a sandy surface. The developers of this robot did, however, delve deeper into the autonomous navigation system in the following article: Development of an autonomous beach cleaning robot “Hirottaro”[5]. To identify its own position, the robot was equipped with a scanning range finder, which measured the position of two poles placed at the corners of the designated work area. The navigation system calculated the position and orientation of the robot using the sensor information and corrected any errors in the path.

In the paper: Monocular Vision for Mobile Robot Localization and Autonomous Navigation[6], they present a new real-time localization system for a mobile robot. They show that autonomous navigation is possible in outdoor situation with the use of a single camera and natural landmarks. To do that, they use a three step approach. In a learning step, the robot is manually guided on a path and a video sequence is recorded with a front looking camera. Then a structure from motion algorithm is used to build a 3D map from this learning sequence. Finally in the navigation step, the robot uses this map to compute its localization in real-time and it follows the learning path or a slightly different path if desired. The vision algorithms used for map building and localization are first detailed. In the paper we can find an experimental evaluation of the accuracy and robustness of the algorithms based on experimental data collected during two years in various environments.

The patent: Autonomous navigation system for a mobile robot or manipulator, from https://patents.google.com/patent/US5758298A/en describes how, even a cleaning robot, can go to its target point without touching known and unknown obstacles in its workspace. In an autonomous navigation system for a mobile robot or a manipulator which is intended to guide the robot through the workspace to a predetermined target point in spite of incomplete information without colliding with known or unknown obstacles. All operations are performed on the local navigation level in the robot coordinate system. In the course of this, occupied and unoccupied areas of the workspace are appropriately marked and detected obstacles are covered by safety zones. An intermediate target point is defined in an unoccupied area of the workspace and a virtual harmonic potential field is calculated, whose gradient is followed by the robot. Mobile robots with such an autonomous navigation system can be used as automated transport, cleaning and service systems.

The patent: Mobile robot, and system and method for autonomous navigation of the same, from https://patents.google.com/patent/US7613544B2/en describes the following navigation system. Disclosed herein is a mobile robot, and system and method for autonomous navigation of the same. The mobile robot includes a communications module for transmitting a light source control signal to selectively control light sources of a landmark array to flicker, an image processing module for calculating image coordinates of the light sources from an image signal, a pose calculation module for calculating position coordinates of the mobile robot, a motion control module for calculating a moving path and controlling the mobile robot to move along the moving path, and a main control module for controlling interoperations of the modules and general operations of the mobile robot.

A lot has already been researched in the area of autonomous navigation for robots. At the moment, there are already many autonome navigation systems. As can be read above, the autonomous navigation for a robot can be controlled in several ways. During our project we will not be concerned with the development or improvement of an autonomous navigation system for a robot. Our fictional end product will be in possession of an autonomous navigation system. This navigation system will be controlled by a mix of the above autonomous navigation options.

Mobility

There is a variety of (concept) beach cleaning robots published. In terms of mobility, a number of different techniques are used.

From a physics perspective, some requirements have to be met to enable the robot to move freely with minimal risk of getting stuck. First of all the robot needs to have a sufficiently big surface area on the sand. If the surface area is too small relative to the weight, it will sink into the loose sand.

Secondly, the robot needs to be able to move forward. For this to be possible the mobility technique benefits form having horizontal grip on the sand. Because the robot works on loose sand, the robot needs to be able to put a horizontal force on the sand towards the back of the robot.

Lastly, the robot as a whole should be of a proportional size compared to the roughness of the sand. The sand has some height differences caused by footsteps and the wind. The robot needs to be able to overcome these. Simple physics shows that the bigger a wheel is, the bigger the obstacles it can overcome.

When exploring the mobility techniques of these robots, there are 3 techniques that are frequently used:

- Tracks

- Regular wheels

- Legs

Legs are not as frequently used as the wheel-based options. This is because legs offer very little normal force on the surface. When working on a surface with loose sand, this normal force is essential for keeping the robot from sinking into the sand and maintaining control on the ground.[7]

Looking at wheels, these have a better technique in terms of staying on top of the sand. However, since wheel use a round object to move the grip on the surface is not optimal. Wheels primarily use the friction of the sand to create horizontal movement. To counter this a lot of robots use off-road tires with a grip pattern which can pull the vehicle forward.[8]

Tracks offer more grip as the wheels are all connected through a track. This offers more surface area on the sand as well as being able to dig in to the sand using grip on the track itself so it can dig in to the sand and create as much friction as it can.

RPC's

Requirements (must be)

- The robot should be able to pick up soft plastics (shopping bags, packaging etc.) that weigh less than 50g.

- The dimensions of the plastics should be smaller than the middle part of the robot, which is 30cm.

- The effective width of the robot should be 100 cm.

- 75% of the sand that is received should be dropped.

- The robot should be able to pick up at least 90% of the plastics that it encounters.

- The grabbing system should be sand and waterproof.

Preferences (should be)

- The robot receives the least amount of sand.

- The robot cleans the beach as fast as possible.

- The robot is feeded by renewable energy.

- The robot knows when its litter saver is full.

- The robot works autonomous

Constraints (has to)

- -

Argumentation Requirements

The robot should be able to pick up soft plastics (shopping bags, packaging etc.) that weigh less than 50g.

Plastic bags will be about the largest pieces of plastic the robot could pick up. Plastic bags weigh on average between 25 and 30 grams [1]. On the beach there is a chance that there is some sand over these plastic bags, making these bags slightly heavier. That is why we have set the maximum weight that the robot can pick up at 50 grams. Items heavier than 50 grams are probably not made of plastic. The robot will then leave these objects.

[1] IVAM, 2007, Evaluatie van de Tassenbol, I. Akker, E. Derijcke en B. Krutwagen, Amsterdam, juni 2007

The dimensions of the plastics should be smaller than the middle part of the robot, which is 30cm. The robot will be one meter wide and will consist of three parts. The two outer parts will consist of two sweepers that will sweep plastic towards the center of the robot. The middle part of the robot will consist of a conveyor belt. This conveyor belt brings up the plastic that the robot encounters and will become 30 cm wide. Because this conveyor belt is 30 cm wide, the robot cannot pick up pieces of plastic that are larger than 30 cm. When a piece of plastic larger than 30 cm comes near the conveyor belt, this piece of plastic will get stuck.

The effective width of the robot should be 100 cm. Many existing beach cleaning concepts do not have a large litter range. In addition, the entire width of many existing concepts is not used efficiently. This requirement is draft to ensure that our robot's litter range is greater than that of existing concepts. We also want to ensure that the entire width is used more efficiently. 75% of the sand that is received should be dropped. As you can see with existing beach cleaning concepts, you can't stop the fact that the concept also taking some sand from the beaches. Of course, the robot is not supposed to pick up sand. The moment the robot has picked up a lot of sand, the robot also becomes heavier. Because of this it takes more energy to drive the robot around. The idea is that sand pick-up is minimized by our concept. We also want at least 75% of the picked up sand to be dropped again. This ensures that less energy is wasted. The robot should be able to pick up at least 90% of the plastics that it encounters. As can be seen with the beach cleaning robot "RF Controlled Beach Cleaner Robotic Vehicle", this robot does not work very efficiently. The robot leaves a lot of plastic that the robot encounters. However, the pick-up system of the RF Controlled Beach Cleaner Robotic Vehicle has been put together very interestingly and could achieve a lot more. Our robot must pick up at least 90% of the plastic it encounters. In this way, our grabbing system works a lot more efficiently than that of the RF Controlled Beach Cleaner Robotic Vehicle and a lot of other beach cleaning concepts.

The grabbing system should be sand and waterproof. The robot we make is a beach cleaning robot. So this robot cleans the beaches. Beaches often consist of sand, so the robot will often have to drive over sand. To ensure that the pick-up system will not crash or break, it must be sandproof. In addition, it is efficient if the robot can work every day and during different weather conditions. The robot will also have to be functional during rainy weather. In addition, there is a chance that the robot will touch water from the sea. To ensure that the pick-up system will not crash when it rains or touches water from the sea, it must be waterproof.

The Concept

A concept had to be devised as a solution to the problem statement. In the problem statement was stated that plastic pieces of wrappings, bags, etc. fall apart into microplastics which is crucial for the well-being of the environment. To prevent this, we will develop an innovative and efficient litter-pick-up-system of an autonomous beach-cleaning-robot. This beach-cleaning robot must therefore be able to clear plastic pieces of different sizes from the beach.

A number of requirements have been drawn up. These requirements must also be taken into account. The beach-cleaning-robot should be able to pick up lightweight soft plastics (< 50 g) that are smaller than the middle part of the robot. In addition, the range of the robot to pick up plastics should be 100 cm. The litter range in width is not large in many of the existing beach cleaning concepts. We wanted to make a robot that would have a more efficient litter range in width. The choice to make the robot one meter wide is based on two variables. The first variable is litter range and the second variable is mobility. By making the robot one meter wide, we ensure that the robot has an efficient litter range and also contains enough mobility to maneuver between obstacles and make sharp turns.

75% Of the sand that is received should be dropped. The robot should be able to pick up at least 90% of the plastics that it encounters. The last requirement is that the grabbing system should be sand proof.

Before a concrete concept could be devised as a solution to the problem statement, a 'State of the Art' was drawn up and studied. This discusses the things that already exist at the moment and which therefore do not require any attention. The following topics are reflected in the "State of the Art": Mobility, Navigation, Litter Detection and Grabbing System. In addition to these topics, existing beach-cleaning robots were also examined. The topic of 'Grabbing System' and the existing beach-cleaning-robots is important for devising a concept as a solution to the problem statement.

While studying the "State of the Art" of the topic "Grabbing System" we noticed several things. Many Grabbing Systems of existing robots are similar. For example, there are many robots that use buckets. The downside of these buckets is that they also pick up shells and stones from the beach. This is of course not the intention when cleaning the beaches. There are also several existing robots that use a system with rotating hooks. These hooks pick up the litter from the beaches, without taking stones and shells with it. It seemed to us that this system worked better than buckets.

The conceived concept, which will solve the problem statement, is inspired by an existing beach cleaning robot, called RF Controlled Beach Cleaner Robotic Vehicle, that uses the system with the rotating hooks[4]. What struck us about this existing beach cleaner is that it has a narrow litter range. In addition, this beach cleaner did not pick up enough litter that it encountered. To solve these adverse factors, we were inspired by a different type of cleaner, namely a street sweeper machine for trash collecting[9]. This street cleaner has two brushes on the front of the machine. These brushes ensure that the machine has a wider litter range. The brushes are placed on the two sides of the front of the machine and rotate towards the center of the machine.

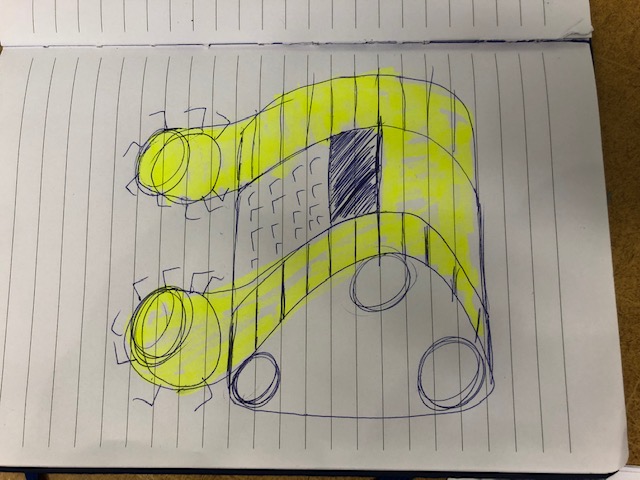

Based on the RPCs and the State of the Art, a concept has been devised as a solution to the problem statement. We saw that some of these robots did not use the full width of their vehicles to pick up plastics. This concept consists of three parts in width. The first and third parts are the left and right sides of the robot, respectively, and consist of two round, rotating hook systems. These two systems rotate toward the center of the robot. This ensures that all trash that approaches the side of the robot is brought to the center. The second part is the center of the robot. This part consists of a rotating hook system in the form of a conveyor belt. This conveyor belt raises all the plastic garbage. We decided on combining side sweepers and a conveyor belt in the middle to make the range width of the robot as big as possible. At the top of the conveyor belt, the plastic garbage falls into a bin. The bottom of this container consists of a sieve, so that the sand that has come along comes back on the beach. The robot runs on tracks. This makes it easier for the robot to drive over small holes and small bumps. The robot is 100 cm wide and therefore also has a range of 100 cm. This range is lot wider than the range of the RF Controlled Beach Cleaner Robotic Vehicle.

A sketch of the concept:

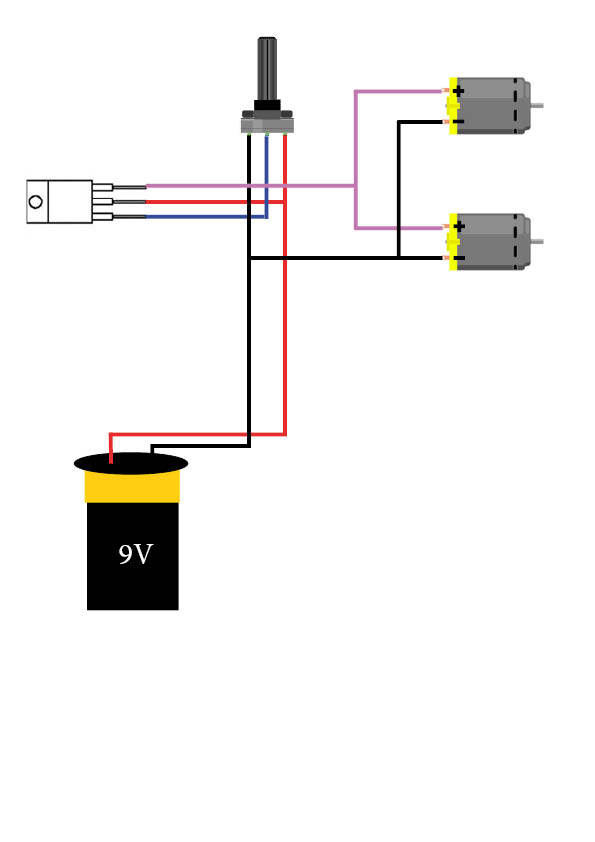

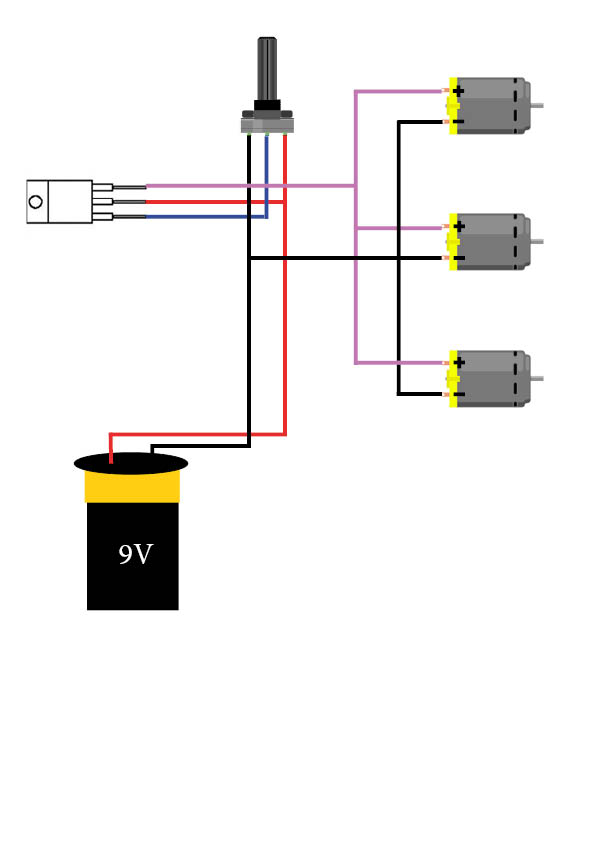

The concept is intended to clean up lightweight soft plastics (<50 g) that are smaller than the middle part of the robot. When an object is too heavy or too big to be picked up, the robot will notice it. We are using 3 dc motors to move the 2 round sweepers and the track. To detect when there is something stuck or the robot has gotten stuck in the sand, one can use a multimeter. You can easily measure the amp draw of the motor the current will jump up significantly when the motor is being held back, has too much friction or when something is stuck between the sweepers and track. Initially, we planned on using an arduino to incorporate this feature. By measuring the current on the arduino and integrating that in a simple if-statement in the code, we could stop and reverse the spinning direction of the dc motors. The robot will turn 90 degrees and continue its cleaning journey. In the end, the decision was made not to use arduino because the dc motors could be easily hooked up to a potmeter and a power supply making it easy to control without using an arduino. This eliminates the use of this feature but it is not necessary for this prototype.

Prototype Development

Step 1

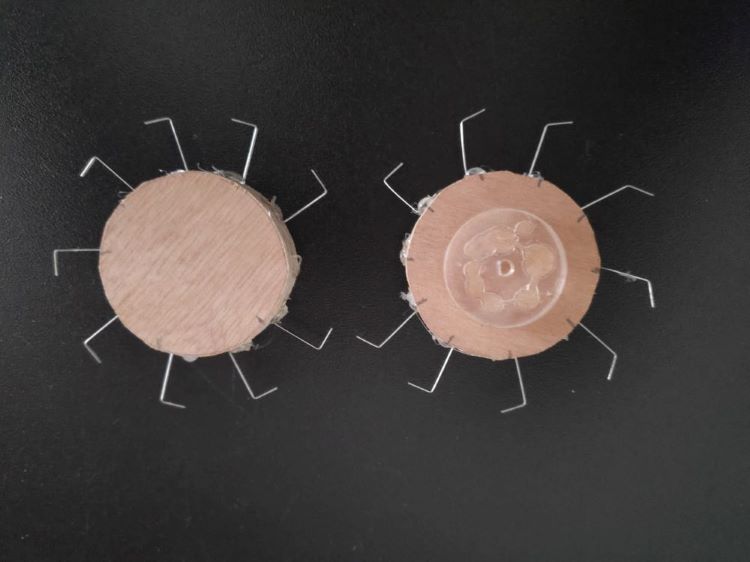

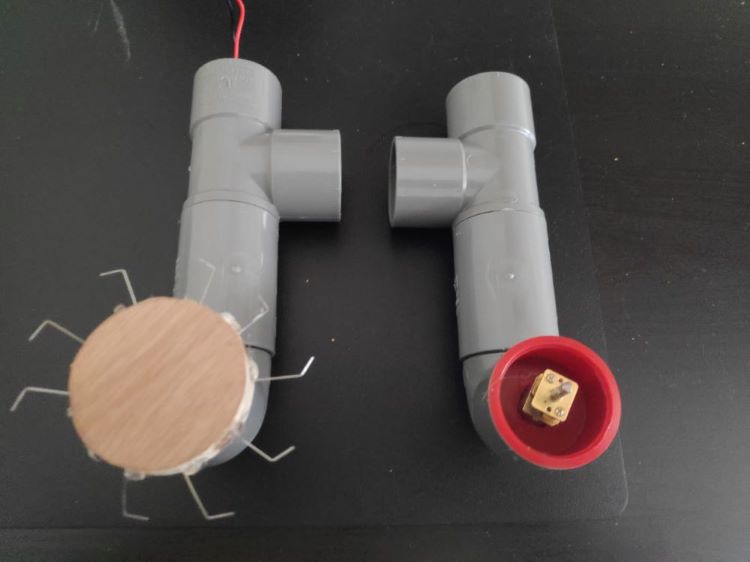

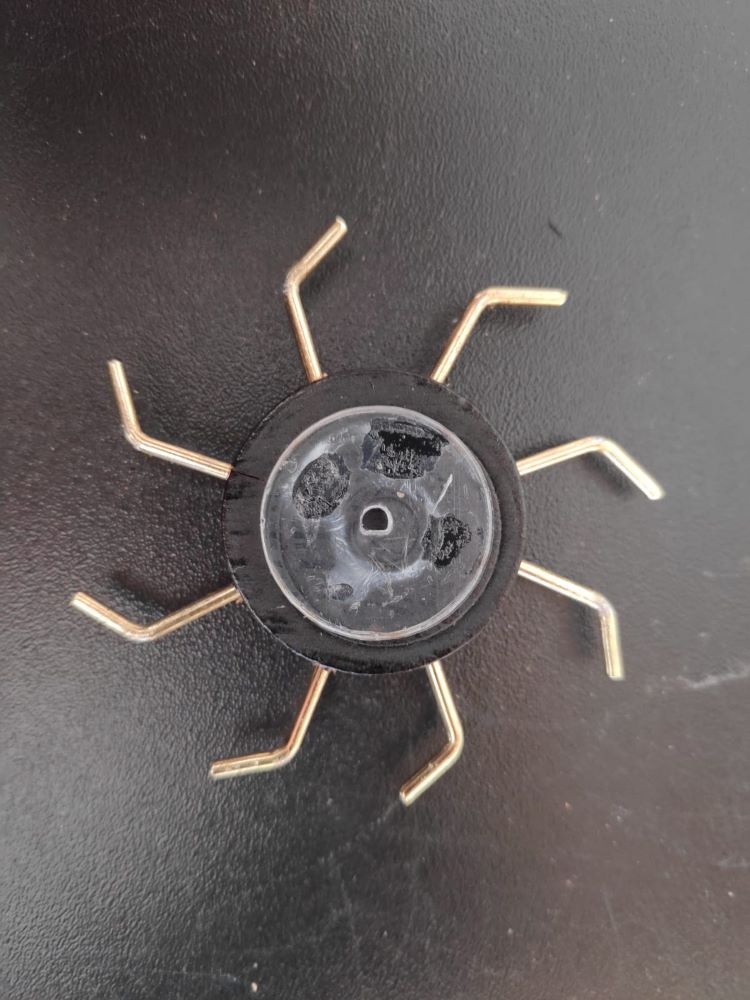

First, a low fidelity prototype of the side-sweepers was made using small wooden disks and staples. These could then be attached to a DC motor to test the efficacy of these parts.

Step 2

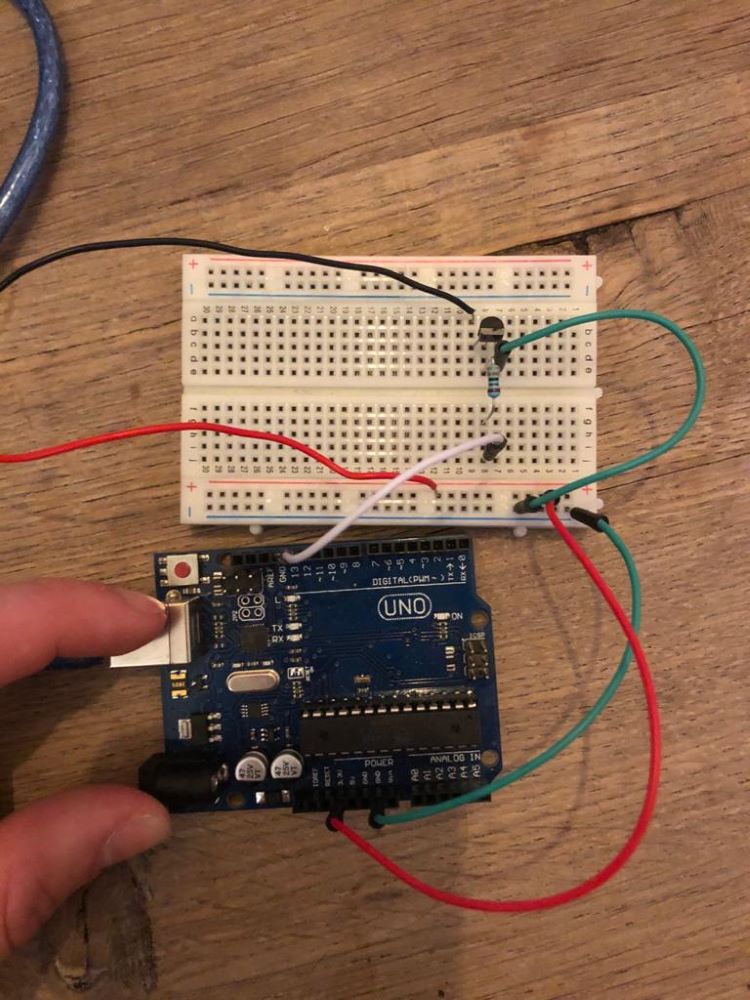

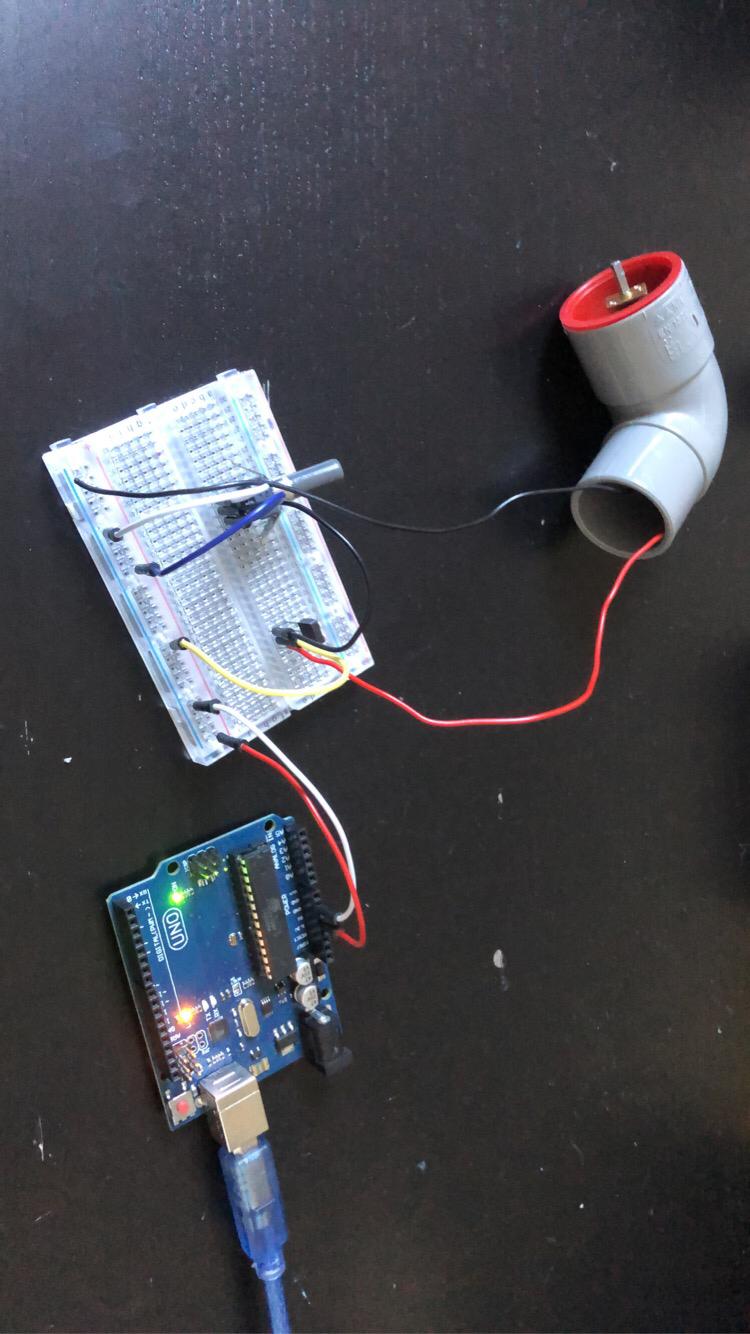

Next, a first version of a circuit was built to control the DC motor with an Arduino Uno. This was the first step towards a complete electrical circuit for our robot.

Step 3

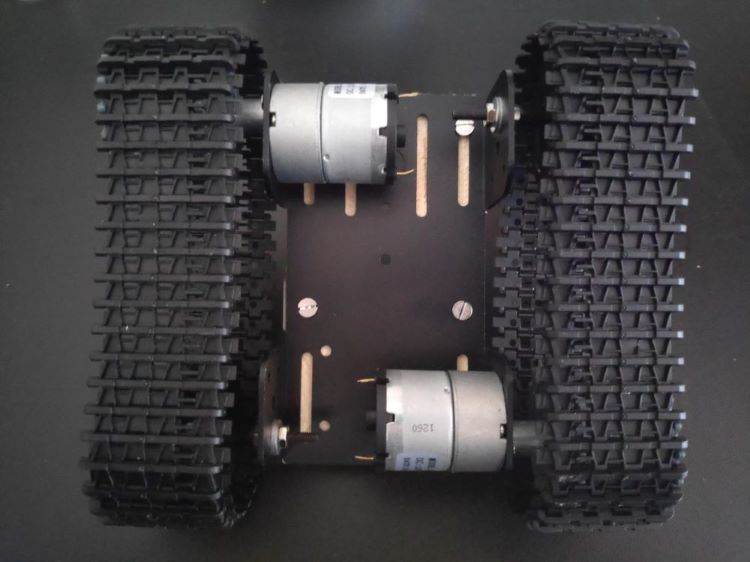

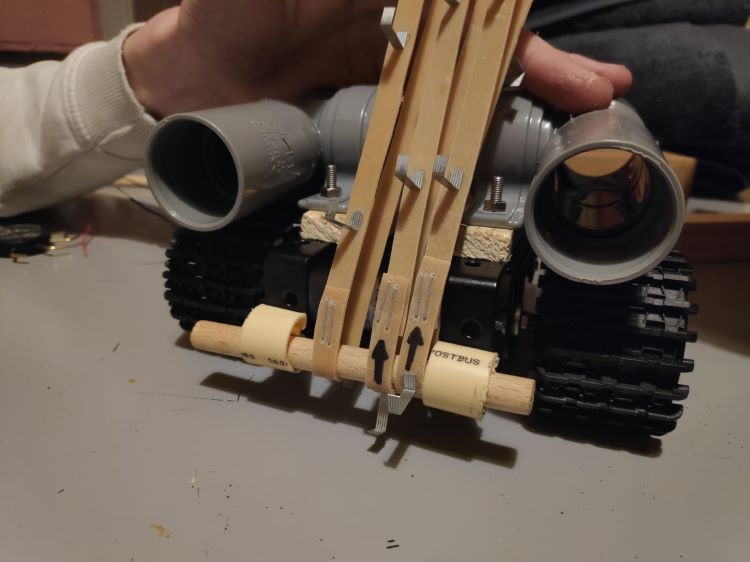

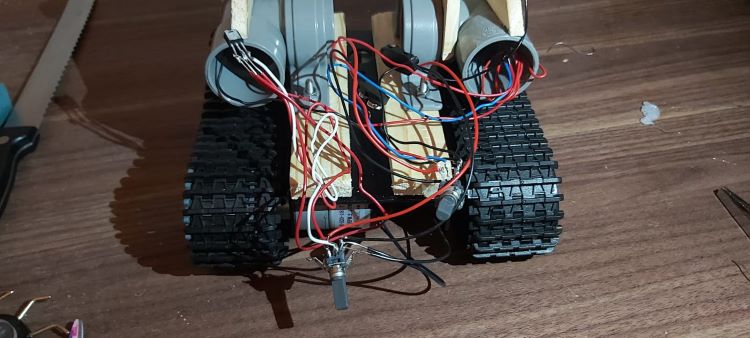

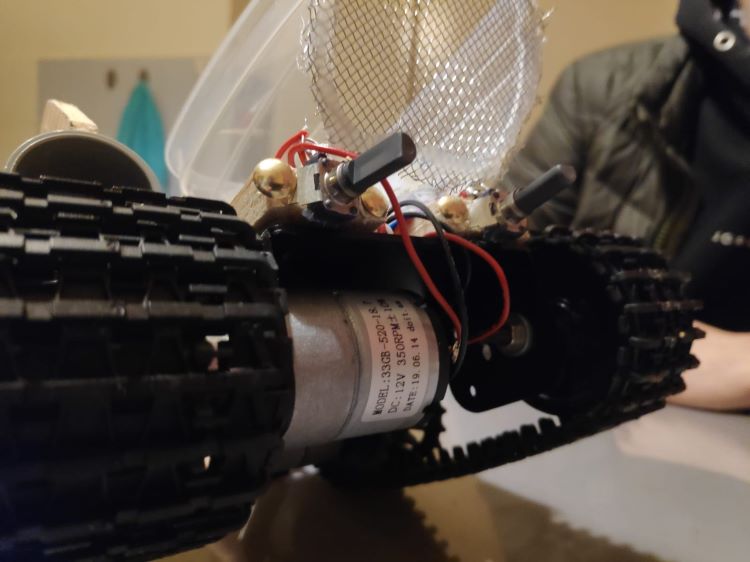

The third step was to build a base for our robot. The goal of this base was enabling the robot to move around and enabling us to build our system on top of it. As stated in the state of the art, track tires are the best option for dealing with an uncertain terrain. To save time and effort, we ordered a kit online and assembled it. This kit contained an aluminum body, tracks and two big DC motors. An ideal base on which we can start to build our robot.

Step 4

Next, two mounts were attached to the base. These will hold the structure that is going to be placed on the base.

Step 5

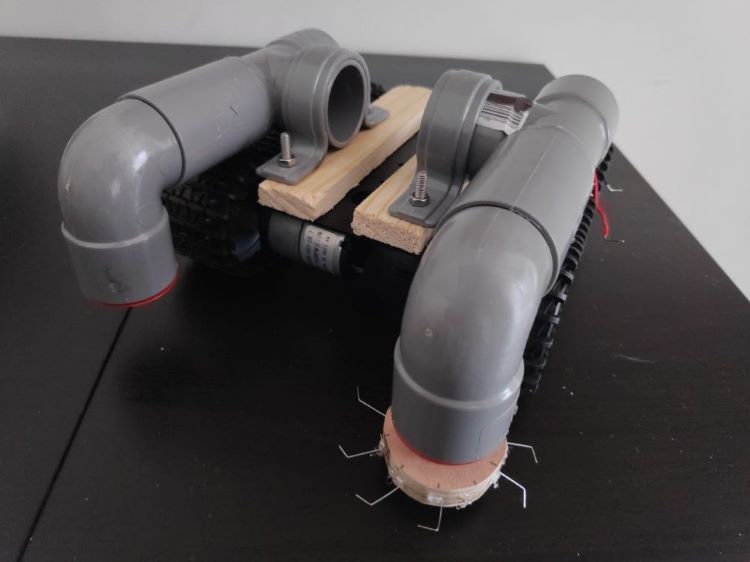

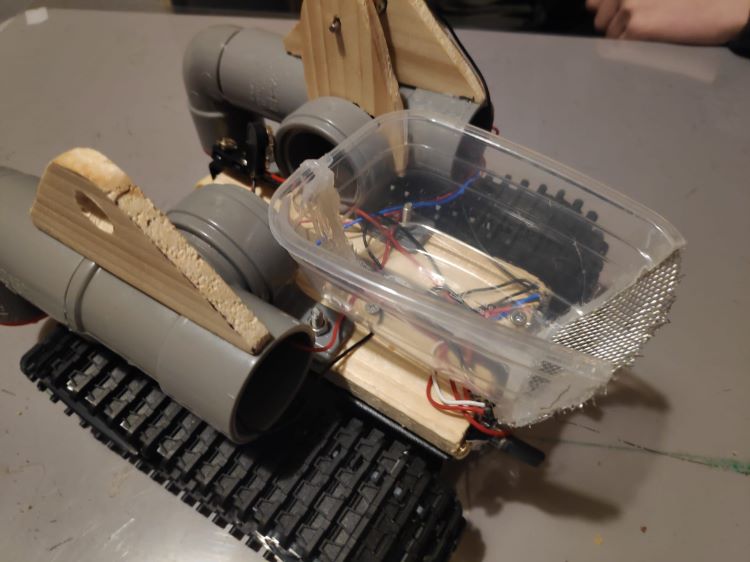

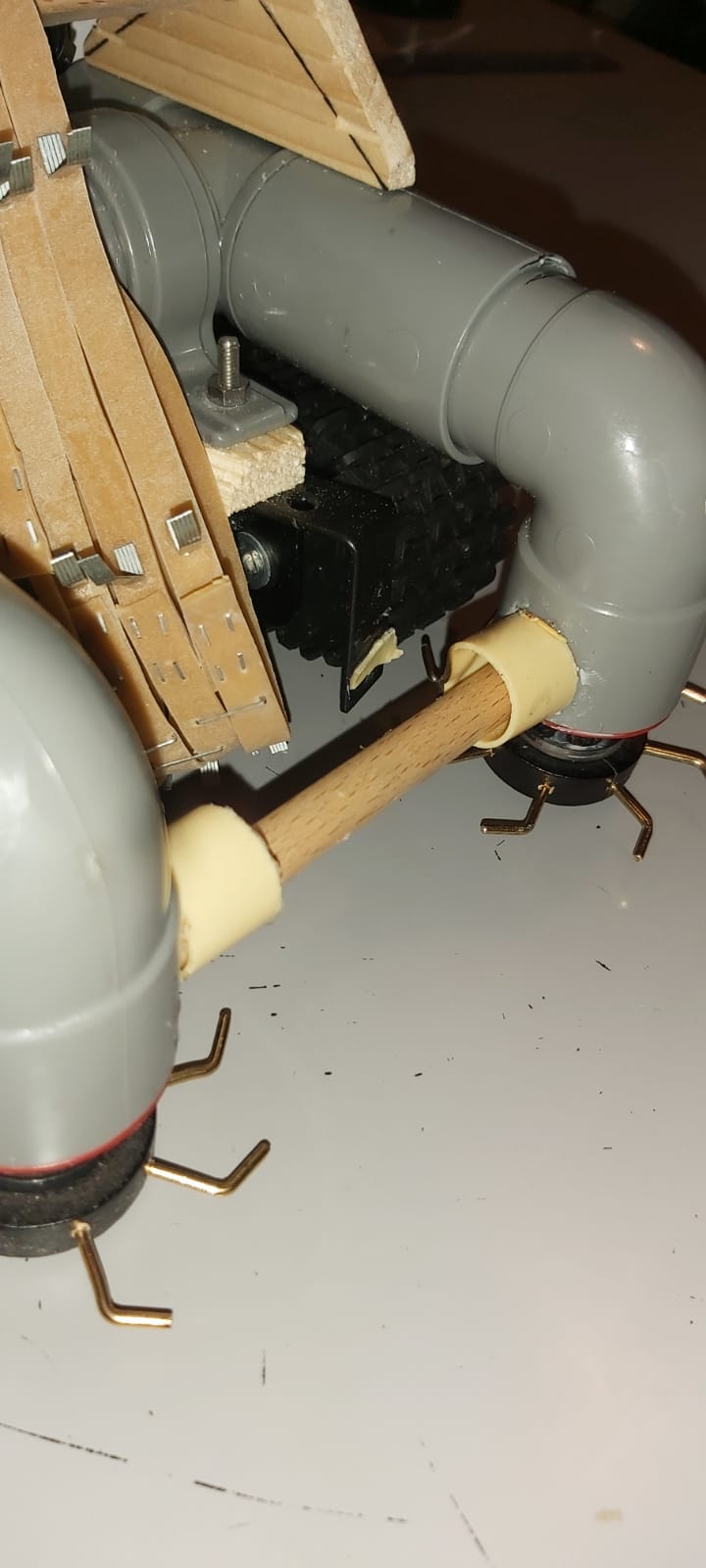

From different kinds of PVC pipes, a structure was made with the goal to hold the side-sweepers in the appropriate place.

Step 6

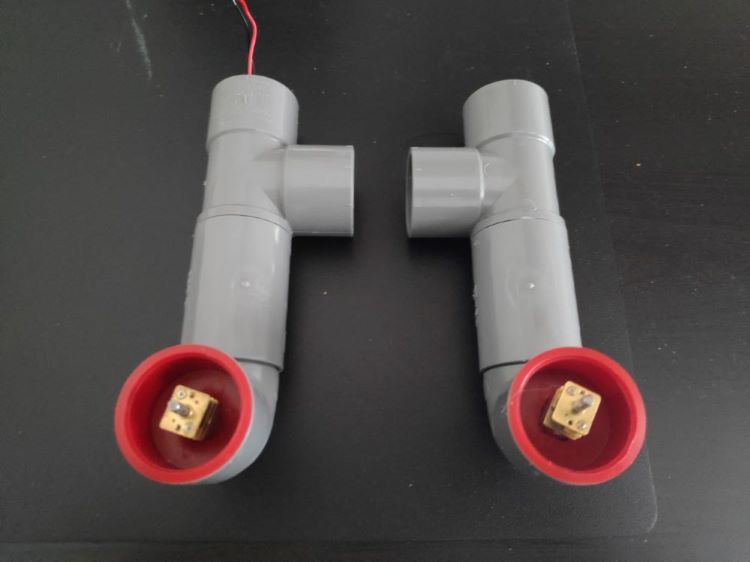

Next, the DC motors were added to these PVC pipes by fastening them in plastic sealing caps.

Step 7

Here, all the parts from the steps above were assembled together.

Step 8

A circuit was built to control the speed of the DC motors using a potentiometer.

Step 9

An improved version of the side-sweepers was made. This version is sturdier and involves bigger hooks.

Step 10

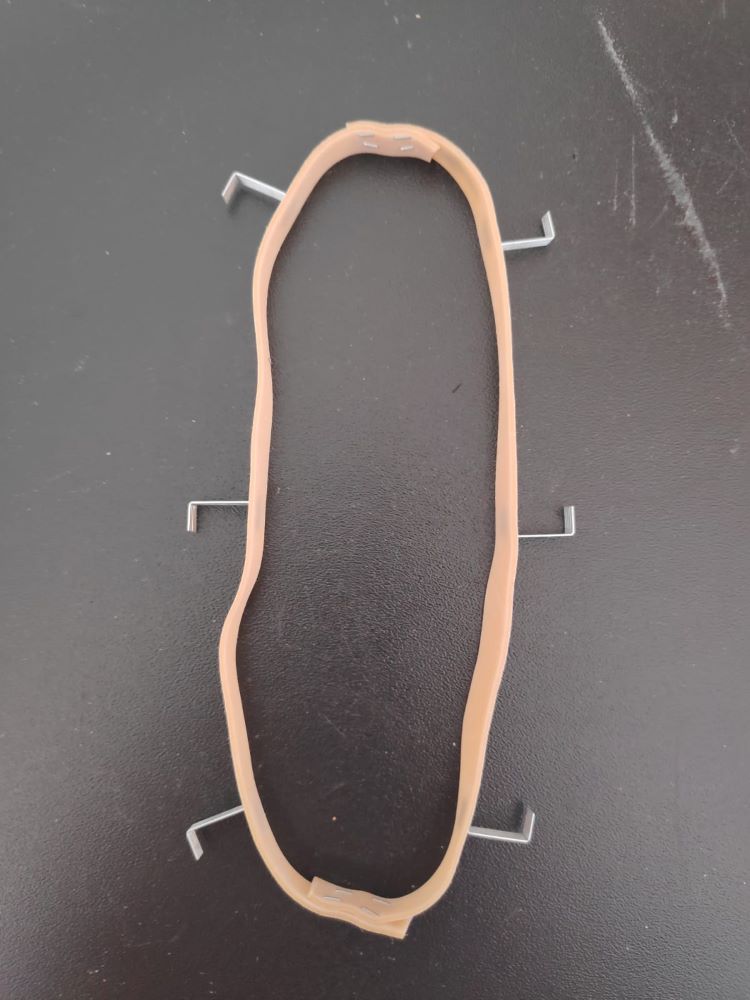

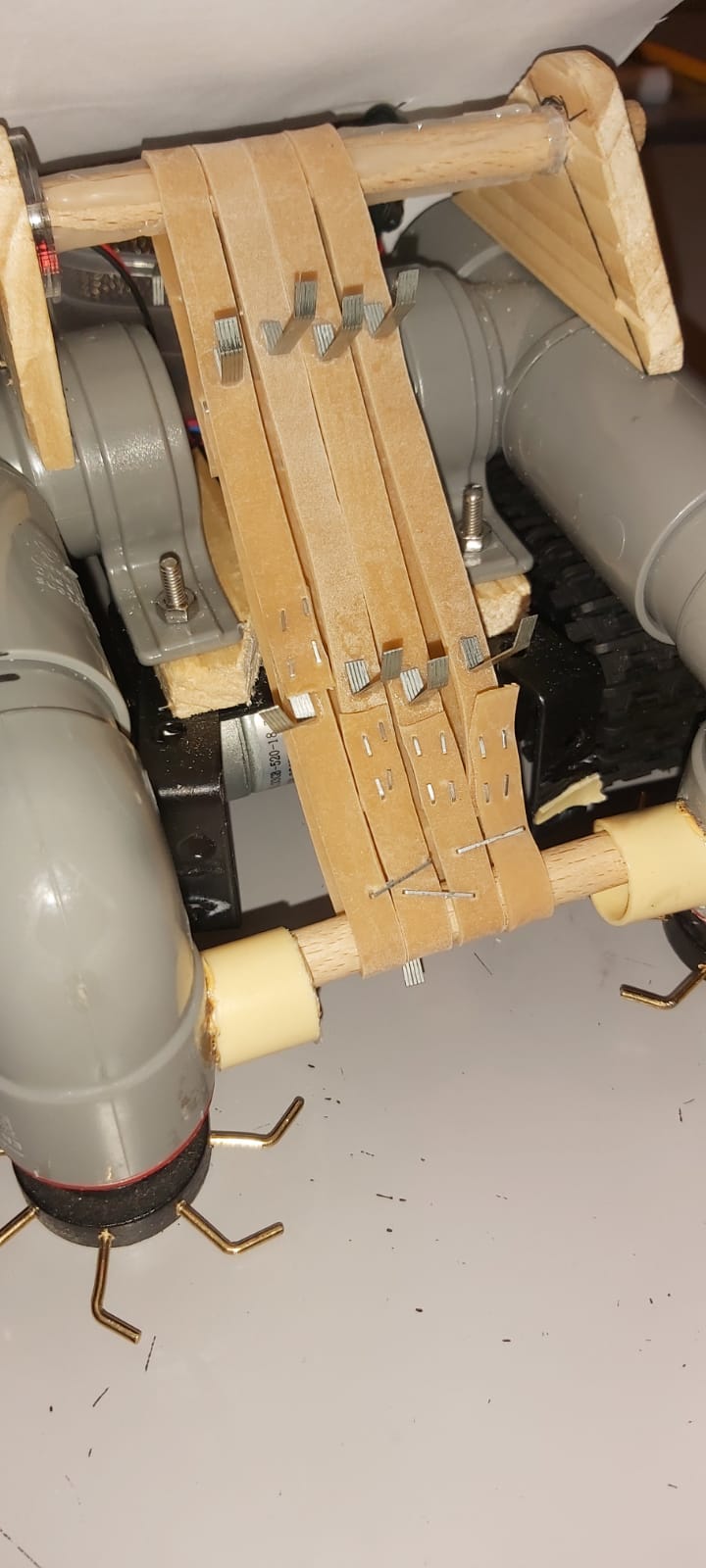

At the same time, the conveyor-belt for the middle part of the robot was made. This conveyor-belt is made up of 5 separate elastic bands attached with hooks. One of these elastic bands is shown in the picture above.

Step 11

Next, the lower axis of the middle part was attached to the robot. This axis will eventually support the movement of the conveyor belt, but will not be driven by a DC motor.

Step 12

The next step was to attach the top axis. This axis is held in place by three separate wooden parts. One of these parts holds the DC motor, one connects the DC motor to the axis and one holds the axis in place on the other end.

Step 13

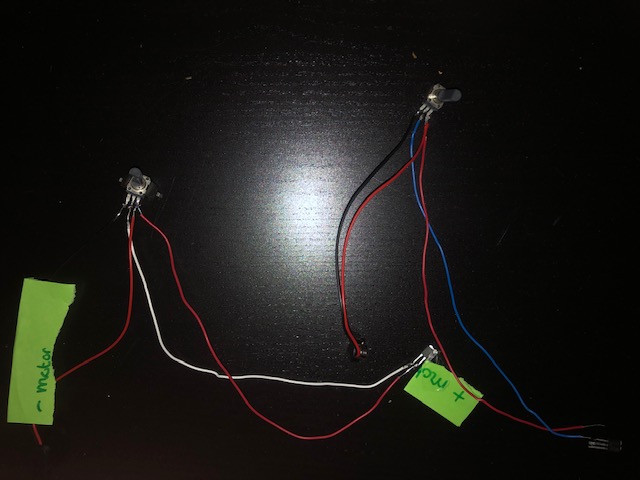

Two separate circuits are soldered together. A circuit has been created to control the speed of the DC motors mounted in the sweepers and conveyor belt. In addition, a circuit has been created to control the speed of the DC motors mounted on the tracks.

Step 14

Here, the complete electrical circuit is soldered in place. All DC motors were connected and could be controlled with potentiometers. Afterwards, the loose wires and components were neatly hid inside the PVC tubes.

Step 15

Next, the plastic container that collects all the litter was attached to the robot. At the back of this container there is a sieve that separates the sand from the litter. When developing the back container, a decision was made to make this as it will prevent a lot of sand being piled up in the storage of the plastics.

Step 16

In order to make it easier to operate the prototype, the potentiometers that control the DC motors were attached to the rear of the robot.

Step 17

A decision was made to move the lower axis more to the front to increase the functionality of the conveyor-belt.

Step 18

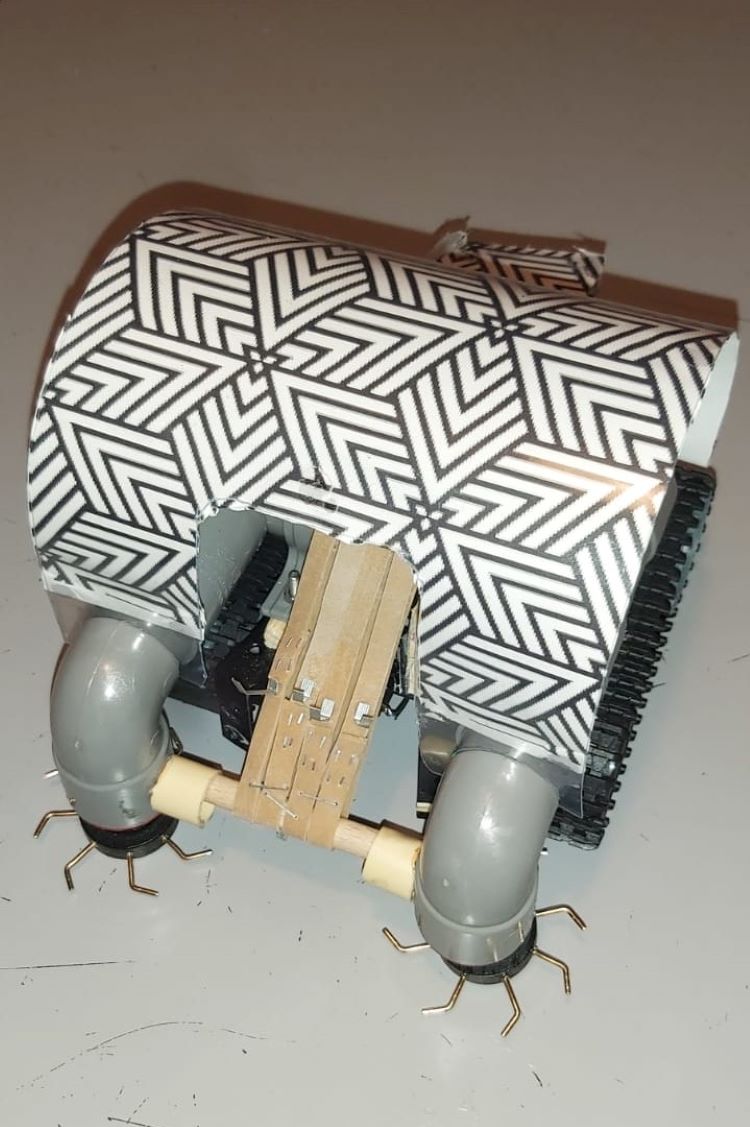

One of the final steps was to attach a plastic case with a livery to the robot, in order to protect the electronics and improve the looks of the robot.

Step 19

Finally, a spoiler was added for improved aerodynamics.

Step 20

This is the final prototype.

Future Work

Our part in the development of this robot has been done. Since the course is coming to an end, we will not be developing this robot any further, which means that the prototype presented above and in the video is our final result. However, we do have some implications for further improvement of the robot, since there are still a lot of interesting aspects to this robot that we have left unexplored.

First of all, it is very interesting to look into how this robot, which has a very sustainable purpose, can be powered by sustainable energy. Use of solar panels (as seen in Solarino), wind turbines or other forms of collecting renewable energy can be the way to achieve a zero-pollution system, but there is still a lot of research that needs to be done. What type of renewable energy is most suitable for this context? How should this type of renewable energy be collected and what does that mean for the design of the robot? Is it possible to completely power the robot on renewable energy? Can the robot be built out of sustainable and/or recycled materials? All questions that are interesting for future work on this robot.

Next, an interesting aspect to look into is the business aspect of this robot. When the robot is finished and presented on the market, it needs to be a financially attractive option for the ones that might want to invest in the robot. If the robot ends up to be ridiculously expensive, third parties will not be interested in it and the beaches stay littered. Thus, for a maximal environmental effect on the world, the robot needs to be as inexpensive as possible. How can this be achieved? Can the robot be designed to be produced and/or assembled locally? How can the robot be multifunctional such that it becomes a more attractive option? These too are questions that are interesting for future work.

Finally, an obvious implication for future work is to build and test the concept in full scale. Now, we have only made a scaled prototype, but to accurately and critically test the concept it needs to be in full scale on a real beach. The results of this test can then be used to redesign the robot and make it more efficient. In order to further develop the robot, this is an indispensable step.

Approach, milestones and deliverables

Approach

- Research into the State of the art

- Defining the problem statement

- Formulating requirements

- Ideation

- Synthesisation

- Simulation

- Prototyping

- Testing

- Evaluation

- Integration of findings in final design

Milestones

- Summary of the State of the art, a defined problem statement and a list of requirements.

- Concrete concept out of the ideation and synthesisation. 1st generation design

- Simulation of the concept.

- Final concept. 2nd generation design

- Prototype.

- Test and evaluation results.

- Final design. 3rd generation design

Deliverables

- Final design

- Prototype

- Complete wiki page

- Final presentation

Timekeeping

Week 1

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 7 | Group meetings: 5, Searching papers: 1, Writing & Reviewing: 1 |

| Wouter Meeuwis | 8.5 | Group meetings: 5, Searching papers: 2, Writing the User and stakeholder part: 1.5 |

| Kevin Pits | 8 | Group meetings: 5, Copyediting and wiki: 3 |

| Teun Schutten | 10 | Group meetings: 5, Writing Problem statement and objectives: 2, Reviewing and correcting: 1, Searching papers: 2 |

Week 2

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 7,5 | Group meetings: 1, User Contact: 4, State of the art 'Mobility': 2.5 |

| Wouter Meeuwis | 11 | Group meetings: 2, literature study: 3, state of the art ‘Navigation’: 2, finding a user and research about the user: 2, Contact the user: 2 |

| Kevin Pits | 0 | |

| Teun Schutten | 7 | Group meetings: 2, Research into litter detection: 2, Searching papers: 3 |

Week 3

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 6.5 | Group meeting: 2, finding a new user and doing research about the user: 2.5, contacting the user: 2 |

| Wouter Meeuwis | 6.5 | Group meeting: 2, finding a new user and doing research about the user: 2.5, contacting the user: 2 |

| Kevin Pits | 0 | |

| Teun Schutten | 7 | Group meeting: 2, Writing State of the art: 3, Defining RPC's: 1, Updating Wiki: 1 |

Week 4

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 12,5 | Group meetings: 6, User contact: 1, Brainstorming: 2.5, Define problem statements: 1, State of the art 'mobility': 2 |

| Wouter Meeuwis | 13.5 | Group meetings: 6, Studying state of the art: 3, Define some problem statements: 2, Brainstorming: 2.5 |

| Kevin Pits | 0 | |

| Teun Schutten | 13 | Group meetings: 6, Writing State of the art: 3, Brainstorming: 2.5, Updating Wiki: 1.5 |

Week 5

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 12 | Group meeting: 3, Brainstorm session: 2, Think of concept 2, Buying stuff for prototyping: 1.5, Finalizing problem statement: 2, sketching: 1,5 |

| Wouter Meeuwis | 15 | Group meeting: 3, Brainstorm session: 2, Think of concept 2, Research in how to use DC motor: 1, Buying stuff for prototyping: 1.5, Exploratory prototyping: 3, Writing Arduino code for testing: 1.5, Testing: 1 |

| Kevin Pits | 0 | |

| Teun Schutten | 13 | Group meeting: 3, Brainstorm session: 2, Think of concept 2, Finishing State of the art: 4, Updating Wiki: 2 |

Week 6

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 15.5 | Group meeting: 3, Exploratory prototyping: 3, Redefining concept: 1.5, Shopping for track car: 1.5, Shopping for prototyping: 1, Prototyping: 5, Updating wiki: 0.5 |

| Wouter Meeuwis | 16 | Group meeting: 3, Exploratory prototyping: 3, Redefining concept: 1.5, RPC’s uitschrijven: 0.5, Concept uitschrijven: 2, Research DIY track car: 1.5, Wiki editten: 0.5, Shopping for prototype: 1, Getting the DIY car to work: 3 |

| Kevin Pits | 0 | |

| Teun Schutten | 15.5 | Group meeting: 3, Exploratory prototyping: 3, Redefining concept: 1.5, Shopping for prototype: 1, Prototyping: 5, Updating Wiki: 2 |

Week 7

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 18,5 | Group meeting: 8.5, Shopping for prototype: 3, Exploring: 1, Making conveyor-top-axis: 3, Assembling PVC structure: 1, Other prototyping: 2, |

| Wouter Meeuwis | 19.5 |

Group meeting: 8.5, Manier vinden om DC vast te zetten in buis: 2, Shopping for prototype: 2, Soldering wires to DC motor: 1, Editing wiki: 2, Making final side sweepers: 2, Try to make a circuit with a potentiometer to control the speed of the DC motor: 2 |

| Kevin Pits | 0 | |

| Teun Schutten | 17.5 | Group meeting: 8.5, Shopping for prototype: 3, Making conveyor-belt: 2, Assembling PVC structure: 1, Other prototyping: 2, Updating Wiki: 1 |

Week 8

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 19 | Group Meeting: 8, Buying stuff for prototyping: 2, Pick up DC motors: 1, Prototyping: 8, |

| Wouter Meeuwis | 22.5 | Buying stuff for prototyping: 2, Pick up DC motors: 1, Group Meeting: 8, Research N-Fet: 2, Building circuits: 3, Prototyping: 4, Wiki editten: 0.5, Research on garbage can: 2 |

| Kevin Pits | ||

| Teun Schutten | 20 | Group Meeting: 8, Buying stuff for prototyping: 2, Pick up DC motors: 1, Prototyping: 6, Updating Wiki: 3 |

Week 9

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 24 | Group meetings: 13, Buying stuff for prototyping: 2, prototyping: 6, Skype meeting: 1, Shooting videos: 2 |

| Wouter Meeuwis | 22.5 | Group meetings: 13, Buying stuff for prototyping: 2, prototyping: 4, Skype meeting: 1, Reasoning: 2.5 |

| Kevin Pits | 0 | |

| Teun Schutten | 27 | Group meetings: 13, Buying stuff for prototyping: 2, prototyping: 6, Skype meeting: 1, Shooting videos: 5 |

Week 10

| Name | Total hours | Breakdown |

|---|---|---|

| Erik Heijerman | 11 | Group Meeting: 4, Writing pitch presentation: 3, Recording presentation: 1, Editing wiki: 2, Editing presentation video: 1, |

| Wouter Meeuwis | 10 | Group Meeting: 4, Making Video Presentation: 3, Editing Wiki: 1, Making Schematics: 1,5, referencing: 0,5 |

| Kevin Pits | 0 | |

| Teun Schutten | 14 | Group Meeting: 4, Editing Prototype Video: 6, Writing Future Works: 2, Referencing: 1, Cleaning Wiki: 1 |

References

- ↑ 1.0 1.1 Gossen, I. (2019, June 20) 95 dagen lang zwerfafval rapen van het Scheveningse strand. Retrieved from https://haagsehanden.nl/95-dagen-lang-zwerfafval-rapen-van-het-scheveningse-strand-1b236404847e

- ↑ DronyX. (2017, 7 april). Solarino Beach Cleaner Robot. Retrieved on 27 februari 2020, from https://www.dronyx.com/solarino-beach-cleaner-robot/

- ↑ The Nation Thailand. (2017, 13 december). Home-grown robot to keep our beaches clean. Retrieved on 27 februari 2020, from https://www.nationthailand.com/national/30333842

- ↑ 4.0 4.1 Nevon Projects. (2019, 3 januari). RF Controlled Beach Cleaner Robotic Vehicle. Retrieved on 12 march 2020, from https://nevonprojects.com/rf-controlled-beach-cleaner-robotic-vehicle/

- ↑ Ichimura, T., & Nakajima, S. (2016). Development of an autonomous beach cleaning robot "Hirottaro". 2016 IEEE International Conference on Mechatronics and Automation. https://doi.org/10.1109/icma.2016.7558676

- ↑ Royer, E., Lhuillier, M., Dhome, M., & Lavest, J.-M. (2007). Monocular Vision for Mobile Robot Localization and Autonomous Navigation. International Journal of Computer Vision, 74(3), 237–260. https://doi.org/10.1007/s11263-006-0023-y

- ↑ Instructables. (2017, 27 september). Robot Crab (Beach Cleaning). Retrieved from https://www.instructables.com/id/Robot-Crab-Beach-Cleaning/

- ↑ Jogal, S., & Sharma, K. (2016). Swachh-Bharat Bot: A Sweeping Robot. Lecture Notes in Mechanical Engineering, 563–568. https://doi.org/10.1007/978-81-322-2740-3_55

- ↑ Zoni, S. (2020). Retrieved 12 March 2020, from https://patentimages.storage.googleapis.com/b2/ba/3f/b7a7790a0497ad/US4754521.pdf