PRE2018 3 Group3

Jump to navigation

Jump to search

Preface

Group Members

| Name | Study | ID Number |

|---|---|---|

| Max Hanssen | Industrial Design | 1257269 |

| Jorick van Hekke | Electrical Engineering | 1225185 |

| Suryanto Horlez | Computer Science | 1286714 |

| Joeri Schults | Mechanical Engineering | 1266330 |

| Jules Vaes | Mechanical Engineering | 1263196 |

Problem statement

The railways in the Netherlands are very vulnerable for all kinds of things. Think for example of fallen leaves, snow, weeds, dead animals, etc. These factors lead to unwanted delays. This autonomous robot is designed to tackle this problem and prevent delays from happening.

Subject

Autonomous railway cleaning robot

Objectives

- The system must be able to navigate through the Dutch railway system autonomously

- The system must be able to recognize the different obstacles on the railway

- The system must be able to clean the railway from obstacles autonomously.

- For special occasions the system must alert the involved companies

- The system must provide a short-term solution for certain problems

- The system must avoid colliding with obstacles

- The system must be deployable at any time

- The system must not hinder the human operated train traffic

Users

The NS and ProRail. Indirect users are the train-users.

State of the Art

The past project of PRE2016 3 Group 3 was conducted in a similar design case. Hence, the wiki of this project was analysed along with the 63 references of their wiki page (numbered 1 - 63).

- Link to the wiki of project group PRE2016 3 Group 3: http://cstwiki.wtb.tue.nl/index.php?title=PRE2016_3_Groep3#Group_3:_Railway_Maintenance_Robots

- Smith, O. (2016). No more commuter misery? Trains fight leaves with lasers. Retrieved from http://www.thememo.com/2016/09/12/train-leaves-leaf-zapping-trains-rail-safety-and-standards-board-are-arming-up-with-microwaves-and-lasers/

- description

- ETS SPOOR B.V. (n.d.). Railmonitor. Retrieved from http://www.etsspoor.nl/producten/meetapparatuur/railmonitor/

- description

- Statistics about railway disturbances in the Netherlands. Retrieved from https://www.rijdendetreinen.nl/statistieken/

- description

- Different kind of disturbances around railway tracks. Retrieved from https://www.prorail.nl/reizigers/storingen-op-het-spoor/

- description

- Article about leaves on the railway tracks. Retrieved from http://www.metronieuws.nl/nieuws/binnenland/2016/11/die-rot-blaadjes-op-het-spoor-waarom-doen-ze-niets/

- description

- Smith, O. (2016). No more commuter misery? Trains fight leaves with lasers. Retrieved from http://www.thememo.com/2016/09/12/train-leaves-leaf-zapping-trains-rail-safety-and-standards-board-are-arming-up-with-microwaves-and-lasers/

- description

- Sorokanich, B. (2016). This Hand-Held Laser Makes Rust Literally Evaporate. Retrieved from http://www.roadandtrack.com/car-culture/classic-cars/videos/a30597/best-rust-remover-laser/

- description

- P-Laser (2017). Laser cleaning applications. Retrieved from http://www.p-laser.com/applications_detail.aspx?AGUID=1f846979-8fea-4745-bcea-663800c027e5&LGUID=8565a502-c109-43ef-b1a1-dfba5f3edbf6/

- description

- Schreiner, M. et all (2008) Handbook on the Use of Lasers in Conservation and Conservation Science. Retrieved from http://www.science4heritage.org/COSTG7/booklet/

- description

- Vega, R. et all (1990). Laser ice removal system. Retrieved from https://www.google.com/patents/US4900891/

- description

- Paper geometry railways. Retrieved from http://crema.di.unimi.it/~fscotti/ita/pdf/Scotti02.pdf/

- description

- Paper wear railways. Retrieved from https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US6218961.pdf/

- description

- Railway monitor. Retrieved from http://www.etsspoor.nl/producten/meetapparatuur/railmonitor/

- description

- Drones with infrared cameras 1. Retrieved from https://www.prorail.nl/nieuws/proef-met-drones-controleren-wisselverwarming-met-infraroodcamera-s/

- description

- Drones with infrared cameras 2. Retrieved from https://tweakers.net/nieuws/86694/prorail-zet-drones-in-om-verwarming-van-wissels-te-controleren.html/

- description

- Railway switches inspection robot Felix. Retrieved from http://research.loccioni.com/en/robotics/felix/

- description

- Europees Spoorweg bureau. System Requirements Specification (SUBSET-026). Paragraph 3.6.5. Retrieved from http://www.era.europa.eu/Document-Register/Pages/Set-3-System-Requirements-Specification.aspx

- description

- European Rail Traffic Management System (ERTMS). Retrieved from http://www.railway-technology.com/projects/european-rail-traffic-management-system-ertms/

- description

- Falch (2017). cont jet 125 2500-26-0-e. Retrieved from http://www.falch.com/products/g588.html

- description

- Baveck Machines (2017). Rail infrastructure - Rust removing brush. Retrieved from http://www.baveck.nl/en/rail-infrastructure/24-rust-removing-brush/

- description

- Tackling a leafy issue, Railway Technology, retrieved from http://www.railway-technology.com/features/feature1457/

- description

- 22

- description

- 23

- description

- 24

- description

- 25

- description

- 26

- description

- 27

- description

- 28

- description

- 29

- description

- 30

- description

- 31

- description

- 32

- description

- 33

- description

- 34

- description

- 35

- description

- 36

- description

- 37

- description

- 38

- description

- 39

- description

- 40

- description

- 41

- description

- 42

- description

- 43

- description

- 44

- description

- 45

- description

- 46

- description

- 47

- description

- 48

- description

- 49

- description

- 50

- description

- 51

- description

- 52

- description

- 53

- description

- 54

- description

- 55

- description

- 56

- description

- 57

- description

- 58

- description

- 59

- description

- 60

- description

- 61

- description

- 62

- description

- 63

- description

Approach

We will conduct a study and analysis and will come up with a design. If time allows it, we will make a shitty prototype as well.

Planning

| Planning | Monday | Thursday | Remarks |

|---|---|---|---|

| Week 1 | Introduction + groups | The plan | Plan finished before Monday |

| Week 2 | Feedback session + research problem approach | Research + contact NS | Complete questions for NS |

| Week 3 | Feedback session + research solution | Research solutions | Complete possible solutions for the system |

| Week 4 | Feedback session + research components | Components list | Complete possible components for the system |

| Week 5 | Feedback session + integrating | integrating | Integrate the components in one coherent system |

| Week 6 | Feedback session + budget calculation | Extra time to complete the above | Gather feedback |

| Week 7 | Feedback session + finalize | Finalize + presentation preparation | Finish remaining tasks |

| Week 8 | Feedback session + finalize + presentation preparation | Finalize + presentation preparation | Make sure everything is according to the assignment |

Milestones

- First group meeting with everyone

- Solutions ready

- Integrating solution

- Final report

- Final design

- Presentation

- A program that differentiates glass, plants, snow from the other trash

Deliverables

- Wiki (report)

- Final presentation

- (shitty prototype)

Who will do what

- Sunny (Computer Science): the software of the design

- Jorick (Electrical Engineering): the electronic components of the design.

- Max (Industrial Design): the look and feel of the design.

- Jules (Mechanical Engineering): the 3D model of the design and the general functioning of the design.

- Joeri (Mechanical Engineering): the 3D model of the design and the general functioning of the design.

- Everyone:comment/help on other peoples work

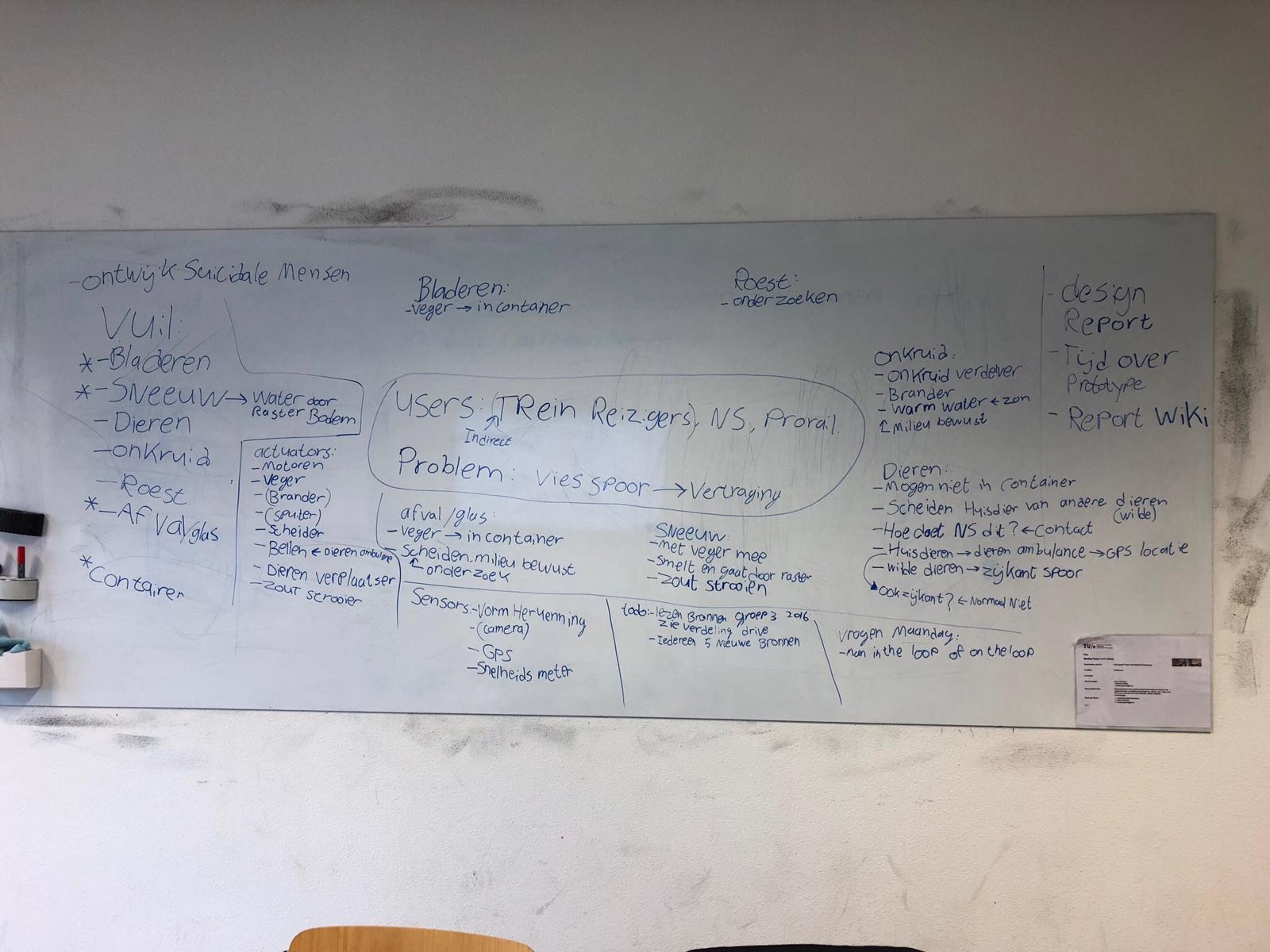

Brainstorm (extra)

Move to logbook