PRE2016 3 Groep1

Presentation 1:

Problem description Model the economical and ecological impact of using robots (drones) in agriculture.

Objectives

The system must

- use drones to aquire data

- analyse the data

- react to the results of the analysis

approach

-research state of the art

-abstract from state of the art

-contact with user

-Create model

-analyse impact

USE aspects

-Societal problem of hunger

-Cheaper food for user

-Cheaper then workers in the long run

Group members

- Guus van Dongen 0960106

- Johan Somers

- Teun de Groot

- Jur Bartels

- Laurence Keijzer

- Bastiaan Wuisman

Project Description

Use Aspects

It is important to check what the USE aspects are, if we wanted to locate the problem and try to invent someting for it.

- Primairy Users: the primairy users for the drones are the farmers. They are going to work with the technology as a tool for the work proces.

- Secundairy Users:

- Tertiary Users:

- Society:

- Enterprise:

Project Planning

Week 1

- Create presentation

- Determine concept idea of drones helping for agriculture

- Research about state of the art

Week 2

- Finish the state of the art [milestone]

- Weeding

- Seeding

- Fertilize

- Harving

- Irrigration

- Disinsectisation

- Contact with User

- Definition of the problem

- Visiting van Borne [milestone]

- Create presentation

- Create planning

- Re-create scenario

Week 3

- Contact with User

- Contact with 'Jan Staal adviesbureau made' (Has contact with many farmers)

- Contact with 'Johannes Strever' (Uses GPS a lot)

- Contact with University Team (Are developing a drone for van Borne)

- Formulate concept [Milestone]

- Start of the model [Milestrone]

- Search for essential information (data)

- Economical

- Ecological

- Company scale

- Global scale

- Software: what software are we going to use

- Update wiki

Week 4

- Implementing the model in software [Milestrone]

- Update wiki

Week 5

- Finished model of application in the Netherland [Milestone]

- Update wiki

Week 6

- Finished model global scale [Milestrone]

- Update wiki

Week 7

- Testing the models [Milestone]

- Changing the models

- Update wiki

Week 8

- Finished Wiki [Milestone]

- Formulated advise [Milestrone]

- Prepare Presentation

- Giving Presentation

State of the art automated argiculture

Weeding

There are some quite exciting technological developments going on in the area of automated weeding. The most important technologies will be discussed below.

Deepfield Weeding Robot

The first far-developed technology is the Deepfield Weeding robot of Bosch, see below.

This robot has GPS navigation to move through the fields with a 90% electrical efficiency. A row of linear actuators is attached to the bottom of the robot. When the robot detects weed is punched one of the actuators in the ground the destroy the little plant. The company claims that the positions accuracy is 2 mm and that it can remove 20 weeds per second. Given 40 weeds per square meter, the robot can process a hectare in three hours. The machine will cost about the same as a midsized tractor (http://www.dairyherd.com/news/german-company-demonstrates-automated-weeding-machine).

Advantages of this design:

- Herbicide-free farming

- Relative fast operation

Disadvantages of this design:

- Only suitable for small weeds

- Only suitable for field with small crops

There is also an other variant of this machine under development. This machine looks almost the same, but it does use herbicides. A greater working with of six to seven meters is possible with foldable booms. This machine will still lead to massive herbicide savings, but with a much bigger capacity potential.

LettuceBot

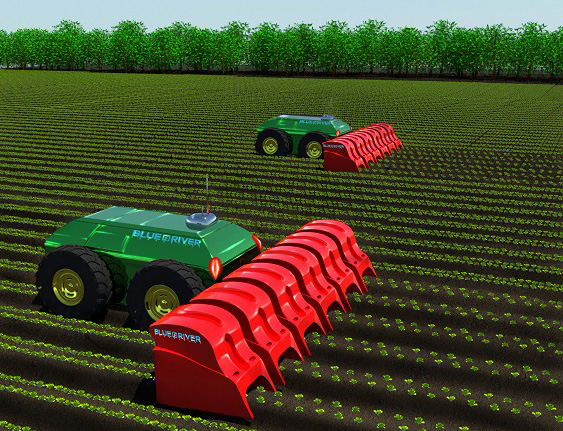

A company called Blue River created a robot which can identify weed and excess planted lettuce plants with the use of image recognition. When it is determined which plants need to be removed, the robot sprays a little amount of herbicide on it. This can result in a 90% reduction of use of perticides. Currently the robot is towed behind a conventional tractor, but Blue River is working on an fully automated version of the LettuceBot.

While driving four miles per hour the precision is a quartile of an inch. The machine can process 40 acres per day and can cared for up to 5000 plants per minute. The machine also collects data about the plants when driving through the field to keep track of the growth and health of the plants.

Advantages of this design:

- It is already a fully functioning machine

- It is really fast

Disadvantages of this design:

- It can only be used on lettuce

- It isn't fully autonomous yet

Naïo Technologies

Naïo Technologies is a company that produces different types of weeding robots. They are suitable for different kinds of users and crops. The one thing that the different robots have in common is that they remove weeds by hoeing. This lets the robots stand out to the opposing companies and robots. The most imporant robots of Naïo technologies can be seen below.

The first robot is called 'Oz' and is suitable for smaller fields. The smalle battery driven robot has a maximum moving speed of 1.3 kilometers per hour. It follows the mounds via different optical sensors and RTK GPS. The robot can turn itself around to start independently with a new mound. It only uses about one euro worth of electricity to weed one hectare.

The second robot is created for bigger farms and uses the same techniques as the Oz robot.

The third robot is called 'Ted' and is used to weed vineyard. The maximum speed is four kilometer per hour and it can maintain a surface of about 25 hectares. This robot also shares the most techniques used in the other robots. The company is working on extending the capabilities of the robot with adding functionalities as mowing, leaf thinning and trimming.

Seeding Machine

There are two kind of seeding machines the normal one and the precision machine.

Normal seeding machine

A seeding machine is a device that is able to sow the seeds by metering out the individual ones. The machine positions the seeds in a soil and covering them to a certain average depth. The machines makes it sure that the seeds are placed at equal distances and depth. Eventually de machine covers the seeds with soil so they can’t be eaten by birds.

Precision Agriculture

For the precision agriculture there is a new design for seeding machines. This model makes use of GPS. This makes it possible that the machine exactly knows where to drop the seeds.

Automated Seeding machines

In 2006 an Australian company designed a machines that is able to plant 6 rows at the time. Eventually the machines had been sold to England and Dutch farmers as well.

Field robot event

In 2016 there was a robot event in Hassfurt in Germany. One of the games they played was a seeding game on the field. The robots has to operate on an area of 10 x 1 meters. The robot should take wheat seeds from a station and has to sow them on the area. There were no specific rules how the machines should provide the task. The robots had to distributes the seeds as even as possible and cover them with soil.

Other kind of mini robot seeders

Other kind of mini robot seeders

Harvesting

There are already a few robots designed for the harvesting of crops. Due to the difference in the way certain crops should be picked, robots that harvest crops are often designed for one specific crop, such as bell pepper, cucumber or any other crop.

Sweeper

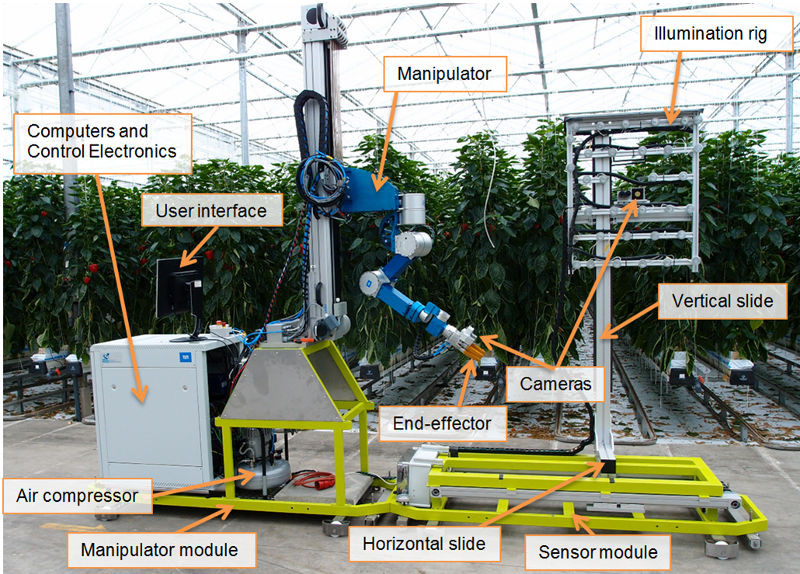

The Wageningen University and Research centre developed a robot for picking bell peppers in collaboration with a group of bell pepper growers. The robot looks as follows:

The robot uses a mechanical arm (The manipulator) to pick the crops and places them into a container. To locate the peppers, it uses multiple cameras to build a 3D picture, while trying to eliminate potential obstructions such as leaves. It has a special lighting rig to prevent bad light from being an issue. This robot was tested successfully in 2014, but was limited to slower speeds at that time due to fear that higher speeds may damage the crops.

http://www.crops-robots.eu/index.php?option=com_content&view=article&id=22&Itemid=22

MIT Robot Garderner

MIT developed its own gardening robot in 2009. The robot has a mechanical arm for picking the crops and a watering pump to water them. A difference with the usual approach here is that the robot does not contain any sensors to analyse the plants, those are placed on the plants itself. Using sensors that can detect soil humidity and other techniques borrowed from botanical science, the sensors broadcast the need per plant, giving this technique a high precision in picking and watering the plants.

Agrobot SW6010

The Agrobot SW6010 is a commercial berry picking robot. It features a rather large truck-like design, but is fully capable of autonomous harvesting of berries such as strawberries. To pick crops it utilises a set of precision arms, with five arms on each side. Using the multiple arms, the robot can reach multiple plants and pick crops more efficiently. There is space for two passengers to check and sort berries that the machine collects. To identify the berries, the system uses the companies patented AGvision system, which supposedly determines the ripeness of the fruit by analysing the colour and form.

Cucumber harvester

Another project of the Wageningen University and Research centre is a robot for cucumber harvesting, which utilised a double camera system and a mechanical manipulator arm to detect and harvest ripe cucumbers. The build and tested a prototype in 2001 and were able to detect 95% of the ripe cucumbers, and successfully picked 75% of those. The vision techniques developed by this robot can be found in multiple modern harvesting robots.

Berry Nice

this creatively named machine is a berry picking machine developed by the Japanese Shibuya corperation. It features robot that moves on rails in contrast to most autonomous robots which use wheels. Using wheels increases stability and speed, but makes adapting the system more difficult as the robot can only move to where there is rails. It also uses 3D stereo cameras to determine ripeness.

CROPS solution

The CROPS solution is a modular adaptable robot to harvest ripe fruits sponsored by the EU. The goal of the project is to develop a robot that can not only harvest one, but multiple types of crops easily. It uses FinRay fingers, which are adaptable grippers to hold a fruit, and knife to cut them off the plant. To detect ripeness, cameras, colour and humidity sensors are used.

https://www.festo.com/cms/en_corp/14014.htm

Visit 'van Borne'

We had a visit with one of the biggest farmers in the Netherlands which makes use of drones for precision agriculture. His name is van Borne and he has a major farm where the plant potatoes. The biggest difference on their farm is that almost everything they do with the potatoes is done by precise machines. They are able to work with a precision of 6x6 meters.

We had a nice conversation with Jacob and we talked about the pros and cons of precision farming and the usage of drones.

He explained us that by using drones you will only get more work to do because you get higher proceed with precision farming. The investment in drones cost a lot of money. But because of the precise measurement of the plant, you are able to reduce the oversupply. This saves a lot of money if you are a big farmer. The biggest problems he struggled with are the legal restrictions. There are so many rules if you wanted to fly with drones that it is hard to work with this technology.

The camera’s they are using are able to collect a lot of data. The camera’s measures 5 different spectra. With the pictures, they are able to make a 3d model of the farmland. All the pictures are being processed so it is able to see where short comings are.

Jacob explained that the precision farming is mostly used with corn of grass. But van Borne grow potatoes because they have a high efficiency. He also explained us that if the bottom of your farming land exists of sand, you have to add liquid manure. When working with the precision agriculture concepts on sand the results are much better.

All machines that are required for executing the process of growing potatoes are designed for operating with GPS. Everything that happens on the land of van Borne will be actuated by a computer.

The only parts what is difficult with the technology is that, it is simple to measure all kinds of things, but it is difficult to process the data to some values you can work with. It will always stay hard to exactly tell, out of a picture, where you should change something for optimizing the grow process.

The next investigation where he is buzzy with is building a new drone with other sensors. And because of the legal restrictions he is observing the possibilities for using drones that fly with a fixed power cable.

References

-Company that makes ground scans and 3D scans with drones: https://3dr.com/ -Drones made for agriculture: https://www.sensefly.com/applications/agriculture.html -Drones that also map the ground: http://www.precisionhawk.com/ -Examples of agriculture robots: https://www.intorobotics.com/35-robots-in-agriculture/ -Some facts and companies analyzed: https://www.therobotreport.com/news/ag-in-transition-from-precision-ag-to-full-autonomy -Benefits analyzed: https://www.geospatialworld.net/article/drones-and-robots-future-agriculture/ -Professors etc. giving their views: http://fruitworldmedia.com/index.php/featured/robots-huge-potential-robotics-agriculture-industry/ -Japanse company that founded a fully autonomous indoor farm: http://spread.co.jp/en/sustainable-farming/ -Project of the EU for percision lifestock farming: http://www.eu-plf.eu/index.php/publications/ -eLeaf technology: http://www.eleaf.com/products-showcase-fruitlook#technology-pimapping -Automated precision weeding: http://www.bluerivert.com/ -Case study of drones in argiculture https://blog.dronedeploy.com/case-study-ce39c9f44e48#.tsnfhikpp -Mechanical weeding robot http://link.springer.com/article/10.1023%2FA%3A1015674004201?LI=true -Seeding and fertilazation robot goo.gl/s2ehLC -Machine-to-machine communication goo.gl/UVJDFS -Framework for argicultural systems goo.gl/RGzsuo -Farmer in the Netherlands which uses the drone: http://www.loonbedrijfthijssen.nl/contact/ -An other farmer in that uses drones: http://www.vandenborneaardappelen.com/ -Bosch Weeding Robot: https://www.deepfield-robotics.com/en/Weeding.html