PRE2015 4 Groep5

Group members

- Aniceta, N.M.F (0876672)

- Boelsums, N.M (0964376)

- Brandts, A (0895917)

- Haenen, S.R.R (0889428)

- Kuijpers, J.J.L (0838617)

Introduction

Problem statement

The world needs to produce at least 50% more food to feed 9 billion people by 2050. But climate change could cut crop yields by more than 25%.[1] With this in mind we need to look for novel solutions to the problem of insufficient food production. This solution will need to take the interests of users, society, and enterprise into account. Moreover, this solution needs to surpass the state of the art by employing cutting-edge technology.

Motivation

Nutrition is vital to sustaining life, and food security is important for political stability and human welfare. We want to address the problem of food availability due to its relevance: continuing population and consumption growth will mean that the global demand for food will increase for at least another 40 years.[2]

Agriculture is an integral part of the European economy and society. It provides the basis for food, feed and non-food products to meet the demands of consumers and a wide range of industries.[3] By designing a solution to the agricultural challenge we will need to take into account the needs of users: like consumers of food, society: the ecological impacts of our solution, and enterprise: the solution needs to be competitive in order to gain an economical advantage.

The agricultural industry is ever advancing, not only is the biological aspect of farming being researched, there are also improvements in automation,[4] and we want to explore the automation of this industry. We want to develop a solution that allows for automation of food production beyond the state of the art, moreover the solution needs to be scalable.

Mariculture

Mariculture is a specialized branch of aquaculture involving the cultivation of marine organisms for food and other products in the open ocean, an enclosed section of the ocean, or in tanks, ponds or raceways which are filled with seawater. two examples of the latter are: the farming of marine fish, including finfish and shellfish like prawns, or oysters and seaweed in saltwater ponds.[5]

In this section we will explore mariculture, and explain why we chose it as a solution to the problem previously stated. Mariculture encompasses a wide range of organisms, from the cultivation of water-based plants to the breeding of aquatic animals. For this project we will focus on the cultivation of aquatic plants,in particular seaweed.

Commonly cultivated seaweed species

- The complete seaweed production features a lot of brown kelps. These long and leathery weeds grow in cold water zones. They must be harvested before the water temperature rises to 21 degrees, otherwise the kelp will rot. Kombu (Laminaria Japonica), is used in a lot of Japanese recipies for soups, as dried snacks, or in salads. Kombu is a dietary fiber and contains high levels of iodine. Kombu is full of iodine and, for that reason, 50% of the Chinese Laminaria production is meant for industrial purposes of collecting idodine. Due to this, laminaria are considered as one of the best renewable resources and it makes up for a major part of the maricultural sector. Japan has made effort to increase the production but due to its labour intensitive nature, the market is not expected to expand notably.[6] Wakame (Undaria) is the type of kelp you will find in your misosoup. With a subtle sweet flavour and satin-like texture it is most suitable for human consumption. The weed is a rich source of omega-3 and helps burn fatty tissue. However, it is also in the top 100 of worst invasive species in cold waters, which is partly caused by aquaculture.[7]

- Gelidium amansii and Pterocladia are valuable red algae that can be found at shallow coasts. They can be used in salads and to make agar, a jelly-like substance that can be used for microbiological research and various industrial purposes.[8] They have been cultured in Korea since the last century, but always on a small scale. There have been various attempts to farm the algae at sea, but the slow growth rate and required non-contaminated waters made it unattractive for commercial cultivation.[9]

- Nori or Zicai (Porphyra) are most famous for composing the sushi wraps. The red algae grow in cold and shallow waters in the intertidal zone. After growing in the sea for 50 days, the weeds can be harvested every 10-15 days. The Nori market is stable, the demand is not expected to grow or shrink in the coming years. In Japan, the annual production is valued at 1 billion US dollars.[10]

Environment

Dead zones

Ocean dead zones are areas with low oxygen levels and hardly any marine life. These areas are caused by agriculture fertilizers that increase the level of nitrogen and phosphorus, also known as eutriphication. The result is a rapid increase in phytoplankton, because they are 'built' from phosphorus and nitrogen. These algal blooms cause deadzones and the number of these deadzones is increasing. As a result, the fertility of the marine life drops dramatically, and in more extreme cases, fish lose conciousness and suffocate. Slow moving creatures on the seafloor are unable to escape. Seaweed is capable of uptaking both nitrogen and phosphorus and replacing it with oxygen. In a study of the increase/decrease of nitrogen and phosphorus levels, where laminaria were cultivated, in is shown that in 24 hours, the levels of nitrogen decreased with up to 263 mg/m3 (at a water temperatur of 1.5 Celsius). In all cases, the levels of nitrogen ans phosporus decreases, albeit more effectively at lower temperatures. [11] For this reason seaweed is also cultivated around fishfarms. Seaweed would be a cheap although perhaps slow solution in the reviving of dead zones.[12]

Climate

Seaweed can assimilate a lot of CO2, about 30 to 60 times the rate of land plants. But this will not solve the CO2-problem, because the CO2 will be released when the seaweed will be consumed. Farmed seaweed only contributes indirectly to a better climate. This is because the seaweed farms can produce food for the animal stock, which would otherwise cultivated at locations where forests would be cut down to create farming land. These spared forests contribute to a net CO2 storage. Seaweed can also be used as a biofuel, for the production of biomethane and electricity. Producing seaweed on a large scale could partly replace fossil fuels, which would result in a reduction of CO2 emmisions.

Locations

To determine the best location for a sea-farm we have to take several aspects into account. The temperature of the seawater should be a suitable temperature for seaweed. For example: the best temperature for growing Eucheuma is 20-25 °Celsius, but there are also species that can grow in water of 10 °Celsius. Seaweed can grow in almost every ocean. The depth of the sea does not matter in the choice of seaweed to farm, because we will only look at cultivating species that grow from the surface downwards. However, for the farm itself the depth does matter. Anchoring the farm is easier in a shallow area of the ocean. These areas are commonly found near the coast. An advantage of locating sea farms near the coasts is that the transport from farm to the secondary users is cheaper. Also building and maintaining the farm is easier if it is closer to the mainland. The dead zones are also located near the seashore, so the dead zones are an extra motivation of locating the sea-farms there. A disadvantage is the shipping routes that are located in these areas. Thankfully, these routes are taken by most commercial ships. This leaves open spots near the coast where there are no passing ships and where the seaweedfarms could be located. See the map ont he side with the important shipping routes at the Dutch coast.[13] An uninteded benefit of seafarms is that they break waves. With the sea levels rising due to climate change, it would be beneficial to locate the farm nearby a shore that is threatened by rising sea levels.

Nutrition

From a nutritional standpoint, the main properties of seaweed, that distinguish them from higher plants, are their high mineral and dietary fibre contents. The high iron and magnesium contents are of particular nutritional interest due to their metabolic or functional properties. In comparison with other sources of fibres, seaweeds contain a high proportion of soluble fibres, which exhibit original fermentation patterns in the large intestine. Red seaweeds have a high protein content, comparable to that of high-protein vegetables. Available data suggest that they have a unique amino acid pattern, complementary to that of most terrestrial vegetables.[14] Edible brown and red seaweeds could be used as a food supplement to help meet the recommended daily adult intakes of some macrominerals and trace elements.[15]

There might be some hesitance in the use of seaweed for human nutrition, but the seaweed that is used as biological filters and food for farmed animals could easily be included in the human food value chain by this route.[16][17]

As seaweed accumulates important substances from the water, it does not only accumulate the desired minerals and trace metals but it also accumulates undesirable metals and heavy metals from the surrounding environment.[18] This can be exploited, and seaweed can be used as a biofilter, but if the goal is nutrition it is important to not cultivate seaweed in polluted water.

Seaweeds are known for their richness in polysaccharides, minerals and certain vitamins,[19] but they also contain bioactive substances like polysaccharides, proteins, lipids and polyphenols, with antibacterial, antiviral and anti-fungal properties, as well as many others.[20] This gives seaweed great potential as a supplement in functional food or for the extraction of compounds. Proteins, peptides and amino acids from seaweed have shown positive bioactive effects in the treatment of diabetes and cancer, and the prevention of vascular diseases. The amino acid profile of some seaweed species is similar to that of animal foods. Extracts of valuable amino acids for feed supplement could be of potential because essential amino acids cannot be replaced by other compounds.[18]

State of the art

Currently, mariculture is not a high-tech affair. Most of mariculture involves manual labor, and in part mariculture is practiced in a non-industrial setting, however we want to focus on industrial mariculture. In shallow-water mariculture the lines to where the seaweed is attached are handled manually, and the shallow waters are traversed by foot. For mariculture out on the open waters, ships are used to get to the farms. For mariculture further off from the shore farmers might make use of cranes to pick up lines and gather crops, this however still involves direct human labor, and sometimes physical labor to pull in lines. For aquaculture — 'indoor' mariculture, in a controlled pond or other body of water — there exist technologies like smart sensors and smart filtration systems. These technologies however are not applicable to offshore mariculture, as it is a rather different environment from the controlled ponds for which these technologies are manufactured.

Our solution to mariculture goes beyond the state of the art, and we envision it has benefits for user, society and enterprise compared to current technologies.

Benefits and drawbacks

Benefits

- Income, employment and foreign exchange (import/export).

- Pond-farms can make use of otherwise infertile and underutilized land.

- Large-scale farms influence coastal water movement, causing enhanced sedimentation and better protection of the coastal areas from erosion.

- Introduction of seaweed culture rafts, ropes, anchors, etc. can increase the surface area of substrate, which may enhance production of other marine organisms in a similar way to what artificial reefs have been shown to do.

- Seaweed culture mostly relies on a natural nutrient supply.

- Seaweed farms offer shelter for other animals, increasing the biodiversity.

- The area below seaweed farms can be used for invertebrate farming such as sea cucumbers.

- Seaweed farms can be placed further offshore to better utilize the offshore resources.

- Seaweed farms are mostly submerged, except for some buoys, so they are not visually distracting.

- When harvests at land fail due to enviromental conditions, the harvests at sea are unaffected. This means that big seaweed farms can provide alternative food during famines. This benefit is mainly relevant to developing countries.

Drawbacks

- Conflicts with other users of the coastal zone.

- Concerns over potential environmental impacts.

- Large surface area required for viable seaweed culture.

- Site preparation may involve removal of native animals, plants and destroying the natural environment (e.g. removing rocks) which may damage the local ecosystem.

- Routine management can result in damage through trampling and accidental damage of the local ecosystem.

- Physical shading of an area can occur. The effects of this have not been well-studied.

- Intensive farming may require additional fertilization. This has yet unknown effects on the local ecological system.

- Large farms and intensive farming may cause diseases to spread more rapidly, causing production loss and other negative effects for the ecology.

- Intensive farming may reduce the nutrient levels of coastal waters, making it harder for other organisms to survive.

Types of farms

Anchored

Anchored farms are static to a certain extent, as they only slightly deviate from their positions due to ocean waves and currents. These anchored farms can provide protection to coastal areas were they are located close to the shore. This wave-breaking property is due to the seaweed that partially absorbs the energy carried by ocean waves. If the farms were to be anchored further away from the shore, one needs to take the depth of the seafloor into account. Moreover, anchoring could potentially disturb life on the seafloor. Anchored farms are universally employed in the maricultural industry.

Drifting

Drifting farms would constitute a more advanced technology. Free-drifting farms are a liability and potentially a hazard if not attended to. Despite the dangers, drifting farms could still be used, and might have benefits over anchored farms. Drifting farms can move with the ocean currents, or make use of wind power to passively drift. However, an aimlessly drifting farm would not have any benefit over an anchored one. The main focus of a drifting farm would be to make it drift smartly — that means that it should be aware of its environment and have actuators to be able to actively move. A smartly drifting farm would be able to autonomously traverse the ocean in order to find optimal spots, for instance a nutrient-rich patch of the ocean, or a location with optimal sunlight.

The drifting farm is a design challenge that we will not take on in our design, however future farms might make use of migratory techniques.

Tasks to be carried out on farms

Primary tasks

- Harvesting — this is the main focus of a farm, to bring in the crop.

- Seeding — after harvesting new plants need to be placed.

- Cleaning — plants need to be cleaned ever once in a while in order to remove barnacles and pathogens.

Secondary tasks

- Checking the quality of the plants — regularly checking the quality of the plants will let you predict the quality and quantity of the total harvest.

- Removing corrupt plants — bad plants need to be removed, especially the sick plants before other plants get infected.

Stakeholders

User

Seaweed farmers

Seaweed farmers are the primary users of this technology. Their main interest is related to livelihood. The farmers will use this technology to make a living, and produce seaweed to sell. The technology allows them to produce more seaweed than ever before due to its efficiency. Moreover there will be health benefits for the farmers, as the strenuous physical labor will be performed by machines. Due to the scalability of this technology, farmers will be able to expand their farms, and because larger production is cheaper production, they can keep increasing their profits. Not every seaweed farmer is the same, however, and farmers with a lot of capital available will be able to invest in the farms and outcompete their competitors with less capital. This inequality divides the group of seaweed farmers in two, and this might give rise to a conflict of interest. However, farmers with less capital available will still be able to sell their seaweed as being more humane, which might encourage certain groups of customers. For the seaweed farmers in general we foresee a net positive.

Food industry

Due to an increased production of seaweed there will be an increase of available seaweed protein and other nutrients from seaweed. As outlined in the section on nutrition, seaweed contains a lot of nutritional substances. Having more of these substances available from a sustainable source like seaweed farming will allow the food industry to source from a more diverse pool of nutrients. We especially foresee seaweed-based nutrients to become cheap due to the economies of scale. The seaweed can be sold directly, or it can be processed. Seaweed can also be used as animal feed and competete with the soy-based feed that is currently leading the market.

Consumers

Consumers will benefit from this technology for several reasons. Firstly the cost reduction will aid consumers as they will have more left to spend. Protein from animals requires more resources, and hence is more expensive than plant-based protein.[21] Secondly plant-based protein has health benefits compared to animal protein.[22] This health benefit does not just depend on having consumers shifting their diet, but seaweed can act as a protein source in processed foods. Finally there is the introduction of seaweed protein and nutrients in general, as outlined in the section on nutrition seaweed contains a lot of nutritional substances. Having more of these substances available from a sustainable source like seaweed farming will give consumers more choice and empower them in following a diet of their choice.

Seafarers

Seafarers will have to navigate around the seaweed farms, and recreational boating will not be possible next to seaweed farms. The positions of the seaweed farms should be chosen such that they do not interfere with commercial shipping routes. If the positioning of the farms isn't handled correctly, seafarers will be negatively effected by this technology.

Inhabitants of coastal regions

This technology would introduce more seaweed farms. These farms can provide protection to coastal areas were they to be anchored close to the shore. The seaweed absorbing part of the energy carried by ocean waves gives it a wave-breaking property. This would mean that inhabitants of coastal regions will be offered more protection than just using levees without these farms. So these inhabitants could indirectly profit from this technology.

Scientists

The farms will be equipped with an assortment of sensors. The sensors will be used to assess the quality of the water and other enviromental factors, in order to make meaningful statements about the seaweed on the farm. The information gathered by the sensors can be used for more purposes than just those in the direct interest of the farm. The data gathered can be shared with scientists, or could be fully openly shared. These datasets can be valuable for science and oceanographic research.

Society

Environment

As outlined in the section on environment above, this technology benefits the environment. Currently the production of food for animals that are raised for human consumption is very costly on the environment.[21] These environmental benefits have a positive impact on society in general. However, due to the robots on the farm wildlife might be disturbed,[23] this introduces a trade-off, the farm has to forfeit some efficiency or speed in order to not harm the environment. If the technology is implemented without regard to the environment it could turn out to be a USE nightmare. But if the technology is implemented in a responsible way, the many enviromental benefits would have a positive impact on society. On local (water quality), and on worldwide (stop climate change) scale.

Government

Partly due to the environmental benefits, and the added economical value the government might be interested in this technology. The development and deployment of this technology could be supported by governmental agencies in the form of grants and subsidies. Supporting this technology could reinvigorate the dead zones as described in the applicable section on dead zones. Combating these dead zones could benefit the ecology and benefit the conventional fishing industry. The environmental benefits could also spur tourism owing to cleaner and safer oceans. This technology could (indirectly) positively impact a nation's (or region's) GDP, so governments will have interest in supporting this technology.

Enterprise

Seaweed farm owners

Seaweed farm owners are one of the largest stakeholders as enterprise entities. This technology will enable seaweed farm owners to scale their business and improve profits. The automated nature of the technology allows for increased productivity and enhanced crop security, due to 24/7 availability of the robots and constant maintenance. There is a possibility of an 'inconsiderate' implementation of the seaweed farms, in this scenario a business would optimize for profit only and would not take other stakeholders into account, this mostly impacts the environment (as outlined in the Society section). While marine life would be disturbed, pollution wouldn't be much of a problem, because polluting the direct environment of the farm would negatively impact the quality of the seaweed.

Food industry

As outlined in the user subsection, the food industry will be able to source more diverse nutritional substances. This increase is supply will be a financial benefit for the food industry.

Culinary industry

The technology would lead to seaweed being more ubiquitously available. This, aside from being used for processed foods, might lead to a shift in dietary preferences. Even if the dietary shift does not take place, access to cheaper seaweed might be an incentive for the culinary industry to innovate. There are many dishes that include seaweed, and there are many left to be discovered. This is not so much a direct benefit, nor is it a contrapositive. This poses a possible challenge for gastronomical innovation.

Subsidized environmental efforts

With the evident environmental benefits of the technology in mind there might be subsidies available for those who implement it. This might be an incentive that could kick-start the automated seaweed industry. These subsidies could give enterprises an edge compared to conventional agriculture or otherwise low-tech aquaculture.

Maritime robotics

In this section we will give an overview of maritime robots and their relevant technologies.

Types of robots

Maritime robots can be classified into several categories:

- Buoy: this robot floats at one spot on the surface. It is mainly used for acquiring data by using sensors attach to the buoy. It can function as an energy generator by using solar panels, also, it can be used as a relay station for communications by attaching a satellite dish.

- Traveler: this robot can actively move across the water's surface by using some way of propulsion. It can be similar to the sensor buoy in its functions.

- Underwater Airplane: similar to an airplane, but instead of like flying through the air it moves through water according to the same principles of fluid dynamics. Can be tricky to maneuver because it is difficult to bring to a halt. This is one of the fastest underwater robots.

- Diving Box: this robot is like an underwater drone, it can move in any direction and float in midwater. However, it is very energy inefficient. The diving box moves up and down based on the principles of buoyancy.

- Etcetera: robots that don't belong to the other categories.

Locomotion

There are several ways for maritime robots to traverse the oceans:

- Jet propulsion — water is taken in and propelled out at high speed, using a directed nozzle makes this very maneuverable.

- Ocean current — passively drifting along the ocean current.

- Propeller — a classic ship's screw to propel forwards and backwards.

- Undulation — the robot moves its 'body' like a fish.

- Wind — using the power of the wind to sail.

Some types of propulsion are passive, such as using the ocean currents and moving by wind power; this is very energy efficient. However, for more speed one should use jet propulsion or propellers.

Sensing

There are many different types of sensors that could be interesting to use at sea.

- Acoustic Doppler current profiler — measures the speed and direction of ocean currents using the principle of “Doppler shift”.

- Camera — for visual data, has a limited range.

- Conductivity — together with temperature and depth information, a good estimate of the salinity can be determined.

- GPS — find the position, only works above the surface of the water.

- Hydrophone — listens for underwater sounds.

- Oxygen — determines the oxygen levels of the water.

- Pressure — determines the depth the robot is at.

- Semipermeable membrane density — a passive sampling device used to monitor trace levels of organic contaminants. When placed in an aquatic environment, SPMDs accumulate hydrophobic organic compounds, such as polychlorinated biphenyls (PCBs), polyaromatic hydrocarbons (PAHs), and organochlorine pesticides from the surrounding waters.

- Sonar — is used to find and identify objects in water. It is also used to determine water depth (this is called bathymetry, which may disturb marine life).

- Temperature — determine the temperature of the water.

- pH — determine the acidity of the water.

Some of these things are very important for positioning, such as GPS for above-water devices, and sonar for longer range object detection. Other types of sensors could be implemented to gather data on the quality of the water — for instance the pH levels of the water could tell whether the seaweed is growing in a favorable environment. The other sensors can also be used for gathering general long-term data for use in science.

Communication

To allow an offshore farm to communicate with a land-based control station (or transmit data between the users/administrators and the farm) there are numerous conventional methods to employ. For instance, satellite communication can be used to transmit and receive data. For our sea-based machines to communicate they would need to partly remain above water, or they would be required to surface to transmit data. If we want to employ machines that can communicate while submerged, we need to find a way to transmit data underwater.

There are two ways to transmit signals under water: using wired technology or wireless technology. A wired solution would require an umbilical cord or tether between two communicating nodes or hosts. This wired solution is quite reliable, and obvious if the device that needs to send or receive data needs to be tethered for other reasons such as the supply of power or for anchoring purposes. However, this wired solution has its drawbacks if a device does not need to be tethered — a tether could hinder its freedom of movement — or if the distance to communicate over is quite large.

Radio waves travel poorly through water, also, the propagation of radio waves gets worse at higher frequencies. So wireless communication using the radio waves — the conventional method above water— is not feasible for our farm. Further down the EM spectrum we will find visible light that could be used for sending optical signals. Optical wireless underwater communication is being researched.[24] But optical waves are affected by scattering. Moreover, transmission of optical signals requires high precision in pointing the narrow laser beams.

Conventionally underwater communications are realized by using acoustic waves. Acoustic wave technology has been in development since the end of World War II. Underwater networking, using a modern network protocol layer stack has also been researched.[25] One aspect to keep in mind when using acoustic communications is that it could disturb marine life,[26] this is a drawback which should be taken into account when deploying an ocean farm.

Energy

In order to let a robot function autonomously on the open sea for a long period, one needs to provide the robot with an energy source. The ocean offers several alternative options for energy generation.[27] Options for alternative ocean energy:

- Tidal energy: generates energy from the currents caused by the tides. The flow makes a rotor or foil spin and the mechanical motion is then converted to electricity. Tidal energy is in development and taking steps to commercial viability.

- Wave energy: generates electricity from the height difference in waves. Wave energy is well developped and applicable in many different settings.

- Salinity gradient: fresh water and salt water mix at the mouts of rivers, where energy can be harnessed from the osmosis process. This technology is in an early development stage with small pilots taking place in Norway and the Netherlands. It is one of the largest renewable energy resources that has not yet been exploited.

- Tidal Range: Uses the difference in sea level with the tides to generate electricity. Fills a barrier at high tide and discharges the water from one side to the other at low tide. It is essentially the same technology as with conventional hydropower.

- Ocean thermal energy conversion:is a very consistent energy source and provides so called base-load power. The temperature differences between deep cold waters and shallow warm and tropical waters is exploited to run a heat engine.

Proposed design

In this section we will propose a design for HASP: the automated seaweed farm. The design takes is based upon the information from previous sections.

- System Design The seaweed farm will consist of two parts. Underwater: a classic, vertical seaweed farm. At the surface: a modern system at for automation. At this part, rails are stretched between buoys, over which a harvesting robot can move. In the middle of the farm, drifts a home base. This is where the monitoring sensors are located, and the data is communicated to the mainland. At the home base, the robot can recharge. At the sides of the surface system,the harvest is collected in nets. The nets are placed at the edges of the farm to be more convenient to the farmer when he or she comes to collect the harvest. If the nets would not be placed at the edges, the farmer would not be able to reach them because the anchor lines of the sytem would prevent a boat from ferning into the farm.

- Modular The entire farm will be made up from modules. All modules will be square and have a surface area that the harvesting robot can cover in 3 hours. After that it will have to return to the base station, to recharge and to dispense of the harvested seaweed. This way it can move efficiently around the farm. The robot can follow a fast path and will have to cross the same paths as little as possible, which limits obstructions when something breaks. When one module need repairing, it can easily be removed and repaired without creating disadvantage for the other modules. Another benefit is that the farmers can try the HASP farm and start out small with one module, and then later expand. The modular construction makes our system flexible, repairable and adaptable.

- Location Our own Dutch North Sea might just be to place to be. With an average temperature of 12 degrees,[28] it is suited for cultivating Laminaria, which will be discussed in the next section. The North Sea is also a former deadzone. From 1985 to 2000, the nitrogen levels had to be reduced by 37% by policies in the Rhine countries. [29] However, the area is still strugling with pollution, and the employment of the seaweed farm could be part of the solution to this problem. The HASP could reduce the nitrogen levels to revive the north sea, whilst the cultivated plants would not have to suffer from overpolluted water. When we consider the busy shipping routes in the North Sea, Zeeland would be the most suitable area, with the least hindrance to commercial ships.

- Farmed type of seaweed The HASP will farm the Laminaria seaweed species. There is a high demand for this particular species, which can not be fulfilled with the current techniques. Laminaria also has a low impact on the environment and grows well in our location's water temperatures. Therefore, Laminaria is the most suitable seaweed to cultivate. As far as temperature is concerned, the optimal growth range for Laminaria is 10–15 degrees Celsius. The maximum survival temperature is 23 degrees Celsius. [30] These temperature ranges tie in with our choice of location.

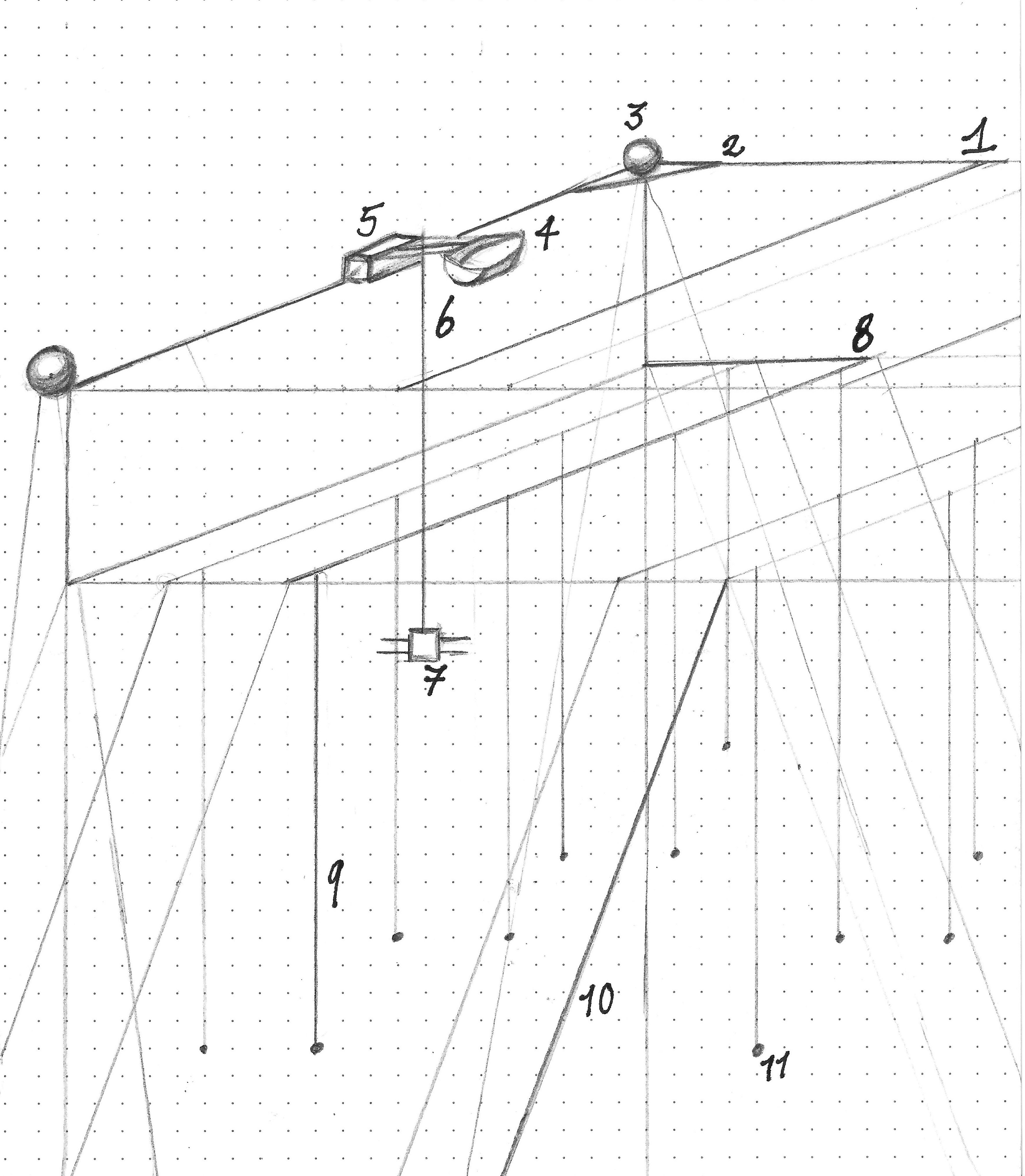

Explanatory sketches

Sketch one

On the surface:

- 1: Rails for the robot's navigation.

- 2: Tracks for passing the buoys.

- 3: Buoy, anchored with two lines to the bottom of the sea. The anchorlines are aligned with eachother so that the buoys can move on the waves, but not towards or away from eachother.

- 4: Floating raft for harvest collection.

- 5: Robot movement component.

Underwater:

- 6: Robot dives down along this telescopic arm.

- 7: Robot cutting and harvesting component.

- 8: Traditional seaweed grow out farm. Starts two meters below the surface.

- 9: Grow out lines on which the seaweed is planted and grown. These lines are 5 meters long and 2 meters apart.

- 10: Anchor ropes, anchor the seaweed grow out system to the bottom of the sea.

- 11: Weights, 400 grams, attached to the grow out lines keep them straight.

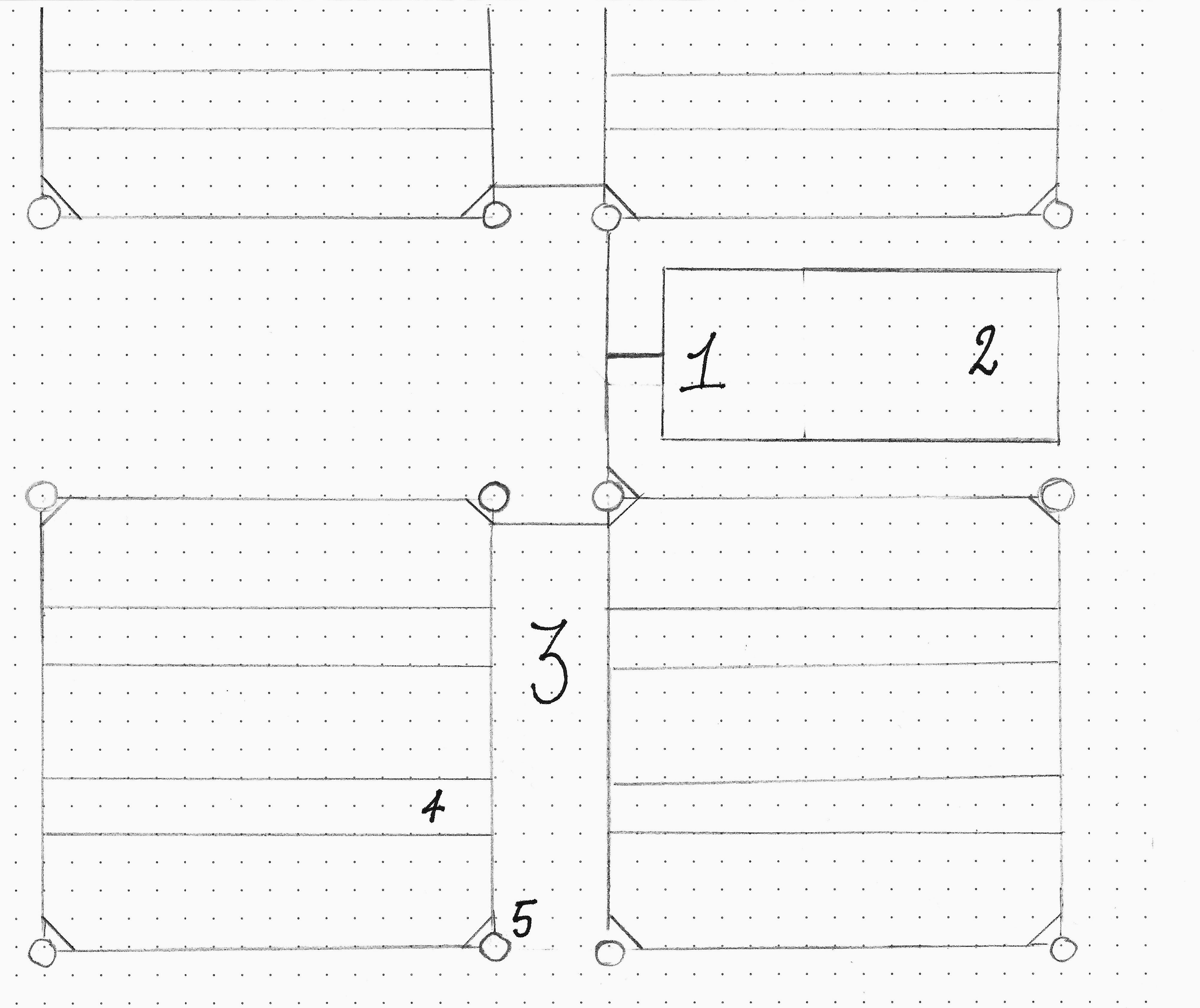

Sketch two

On the surface

- 1: Home base. This is where the robot charges. It is also a sensor buoy and communicates enviromental data to the land.

- 2: Harvest collection net (partly submerged).

- 3: The system's modules.

- 4: Rails for the robot's navigation.

- 5: Buoys.

Automation

Seeding

Like at normal seafarming, the young seedlings will first need to be grown at land in a greenhouse in the summer, when the water is hot. Mid-November, when the seedlings have grown 10-15 cm, they need to be planted at the seafarm. The seedlings are attached to the vertical lines to grow out, with the upper plants receving more sunlight than the lower ones. [31] We have not thought of a way to automate this task, this means that the farmer will have to do it manually. Young Laminaria seedlings will be planted at 5 centimeters apart, making up for 100 plants per line.[32]

Control and hygiene

There are several diseases that could affect the seaweed. These diseases are caused by bacteria or by enviromental factors. [33] Control of seaweedfarms is currently done by the farmers who assess their seaweed visually. The HASP will use sensors to control the health of the crops. Data would be collected about: illumination (too much or too little light causes rot), fresh/salt water level, pollution and micro organisms. More details about the sensors that the HASP will be equipped with can be found in later sections.

Because all of the diseases require different treatments, it is difficult to automate these too. The automation costs would most likely not balance out the profits. Therefore, the system will only alarm the farmers when the enviroment of the seaweed is turning hostile, then, the farmers can decide themselves if they want to take measures.

Harm caused by water grazers like fish can be minimized by placing the farm in deep waters, away from the coastal fish and the creatures on the seafloor.

To maintain the general hygiene of the crops, the harvesting robot can be deployed as a cleaning robot. After it graps some seaweed it does not cut it off, but does a little wiggle. In that way any sediment, or organisms that have attached themselves on the kelp are shaken off.

Harvesting

Harvesting can start in April. Laminaria grows faster in winter and slower in summer, with an average rate of 1.1 cm per day in May. This makes up for 2.5 meters a year. The plant can regenerate when it has been trimmed, but will continue to grow slower. The normal age with this practice does not exceed 4 years.

North Seaweed is a large supplier of seaweed in Europe and is currently active in Zeeland (more about that later). They have stated that harvesting seaweed at this location is the largest practical problem.[34] Therefore we have decided on focussing on the automation of the harvest, by buidling a robot.

We will automate the harvesting process with a robot. The robot moves along rails at the surface that are aligned with the underwater grow out lines. Because these lines are all 2 meters apart, the robot 'knows' where to collect the seaweed. It dives down at the location of a line and starts to grab and cut of the kelp. When the robot cuts off the seaweed it has to dispense it. Returning to the homebase would be too time consuming and therefore the harvested seaweed will be collected in a small container at the surface where the robot is located. The harvest is eventually collected in a net at the edge of the farm. Here the seaweed is stored underwater, to prevent it from rotting. The farmer can then easily collect his harvest by simply emptying the net in his boat.

Drying

It seems very inefficient to dry seaweed on the open sea; drying machines are expensive, do not floa, and take up a lot of space. When one wave flushes over it, all the drying could have been for nothing. For that reason, seaweed must be taken to the mainland to dry. We are not interested in looking into solutions for drying on the water.

Communication

Sensor readings about the enviroment are daily communicated to the farmer and perhaps the research agencies that make use of the data. In case of critical levels of salinity, light or pollution, a warning is send out to the farmer so that he or she can check the seaweed on diseases.

Aside from communication to the mainland, the farm will also communicate its location to ships in order to prevent collition.

At the homebase, the harvesting robot will receive its instructions and mapping, before it leaves to It is not possible to send instructions real time, because of the signal distortion in water.

Energy

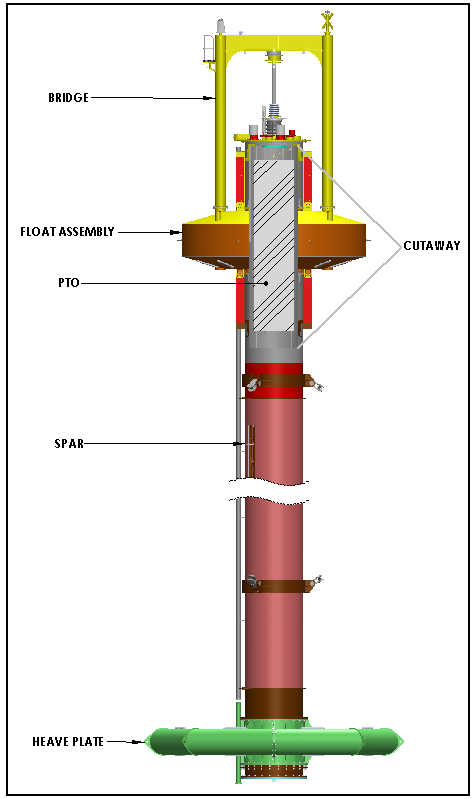

With the climate crisis that humanity is facing, it would be highly unwise to use fossil fuels, as to not contribute to global warming. Therefore, our farm will be powered on renewable energy sources. If system is capable of generating its own energy, it will be a lot more autonomous and low on maintenance. The most used renewable energy sources are wind and solar. However, the ocean offers many alternatives. Wave energy would be the most suitable for our design, because it does not require temperature differences, large surface areas, or specific locations. There are many different technologies for harnessing energy from the waves, ours must remain at one spot and be small. The powerbuoy developped by "Ocean power technologies" meets these requirements. The smallest version, the PB3, has a power capacity of 8400 Wh/Day at 80% availability. It has been proven to survive extreme weather conditions, such as hurricanes, and could dissipate the large surplus of energy it produced at waves of up to 15 meters. [35]

The robot's motors use 27 kW/h and can run for three hours after fully charging.

Big Data and IoT

The farm comes equipped with a lot of sensors to monitor its own condition and its environment. Using all of this data one can analyze it in real time, and after collecting more data extrapolate long-term trends. With all the robotic agents on the farm, combined with the data collected, the farm can be administrated remotely. The farm can be made smart to send out maintenance calls on its own accord. The big data opportunity empowers farmers to have a more clear oversight on their crops. Compared to conventional agriculture data collection is much easier on our farm — instead of taking soil samples a couple of sensors could constantly survey the water.

Sensors to be deployed for the control of the seaweed and disease prevention:

- Camera

- Conductivity sensor

- Oxygen sensor

- Semipermeable membrane density sensor - to check wether any harmful micro organisms can harm the crops.

- Temperature sensor - when the temperature rises above 21 degrees Celcius, the Laminaria will rot.

- PH sensor

- Sonar

Additional sensors can be added according to the data needs of ocean researchers.

Science

The data collected by the farm and its robots can be shared with scientists and governments. More farms mean more sensors and thus a larger sensor size. This data would for example be very useful to The European Marine Observation and Data Network (EMODnet) on which engineers and scientist can find all the data available about the european waters. The European Commission has started Marine Knowledge 2020 with the aim to bring to bring all of the marine data from different sources together. This initiative exemplifies the need for marine data.

Robot prototype

Design process

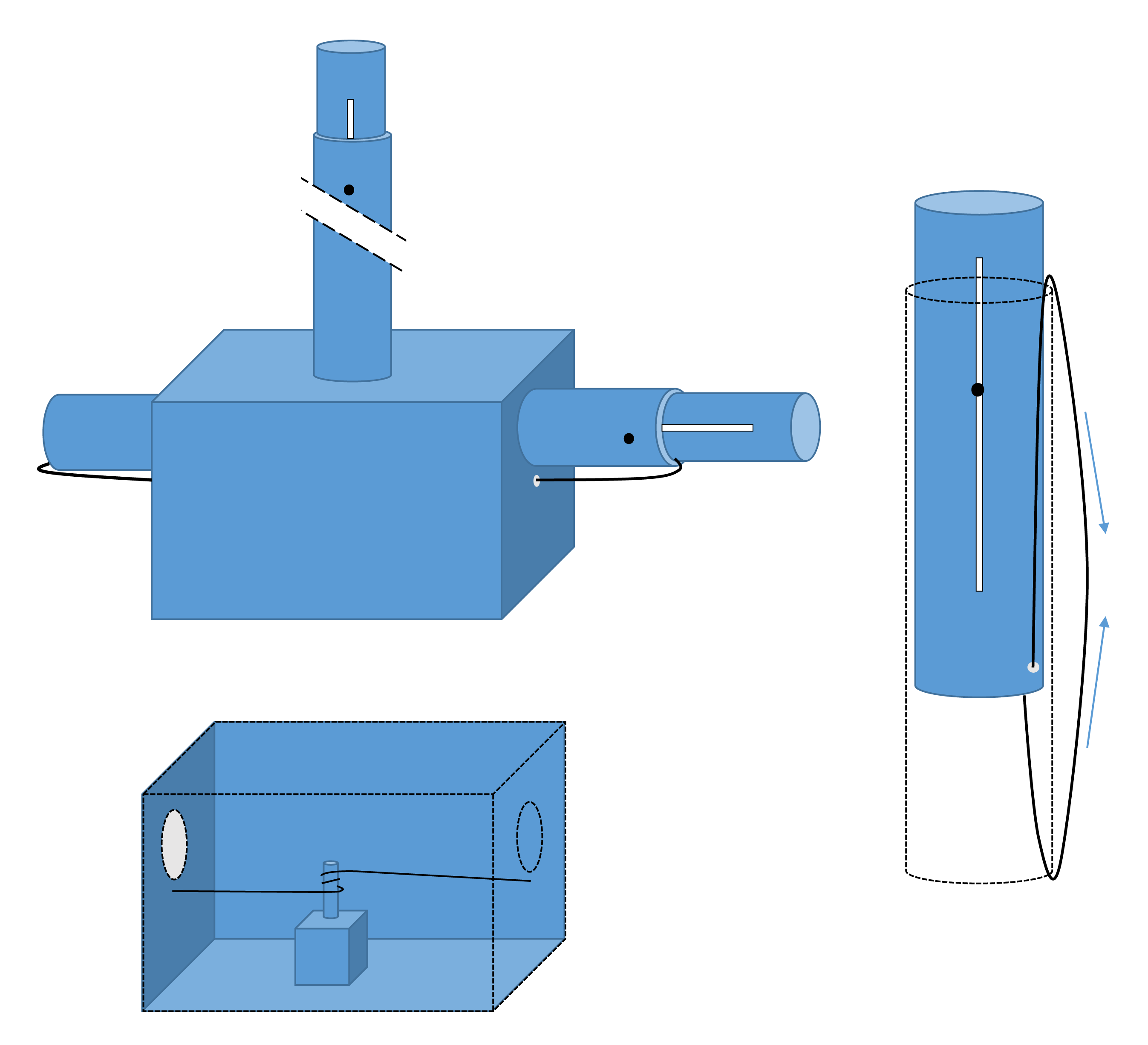

The design for the prototype consists of three components, one for the movement, one for grabbing and cutting and one for the Arduino and battery. The robot moves along a cable, for our prototype we will use a bicycle chain. The robot has three gearing wheels for a stable movement along the cable. The gearing wheel in the middle is driven by an engine. The component with the Arduino and the battery is hanging below the movement-component, just like a chairlift. This component should be heavy enough to sink, this is necessary to keep the bicycle chain on tension. This is the only component that should be waterproof, because it contains the Arduino and the battery. Below this component is the cut-and-grab-component, and is joined to the mothership with rope or a telescoping arm. This rope or telescoping arm is needed for a vertical movement, the robot should be able to cut at different depths. The claw should be able to grab seaweed that might have flowed away a bit, so the claw should be able to move horizontal. This happens by a telescoping arm. The scissors should be placed above the claw, otherwise the robot would cut seaweed that is not hold by the claw.

Technical description

The telescoping arm move upwards and downwards by pulling the rope downward or upwards, respectively. The rope is winded on a spool which could be rotated by an engine. The figure below shows the telescoping arm at the right hand side and the frame of the robot at the left side.

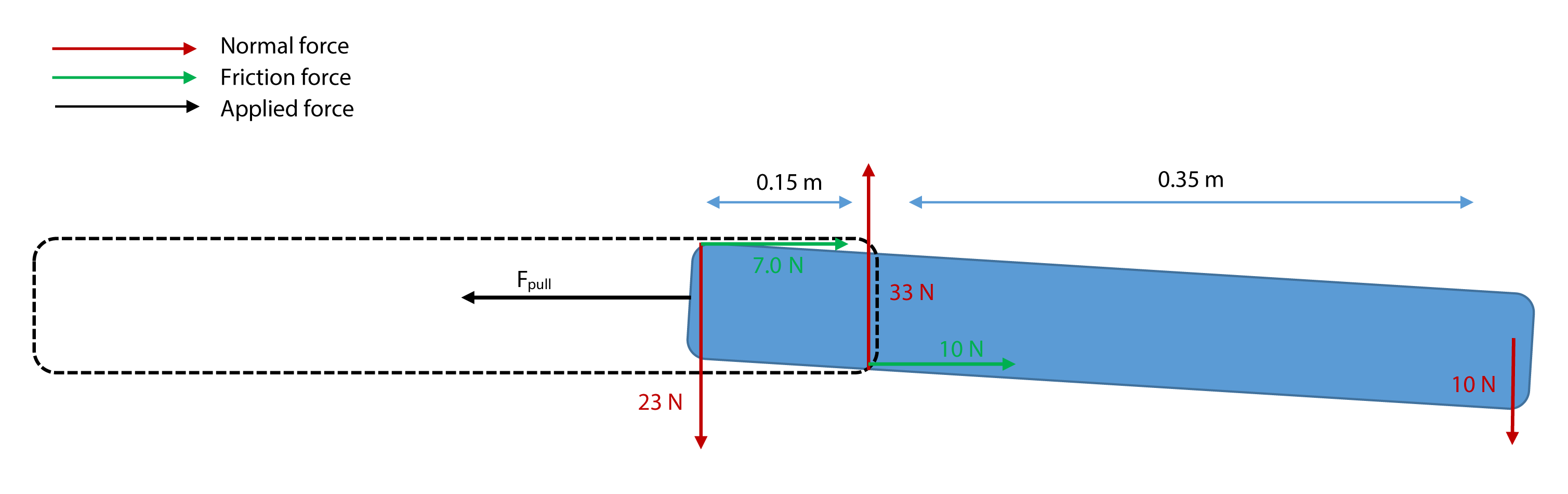

The estimated maximum weight at the end of the pipe is 1kg that equals a force of 10N. The force at the left side is then 23N, computed with F1∙r1=F2∙r2. The Normal force in the middle, which should cancel the other two forces, is 33N. The friction force if given by Ffriction=μs∙Fn. The friction coefficient (μs) and has a value of 0.3 for plastic on plastic. This results in a friction force of 7.0N and 10N for the left top side and bottom side of the pipe, respectively. This is showed in figure x. Thus the maximum friction force between the plastic pipes is 17 N. The figure below shows a schematic representation.

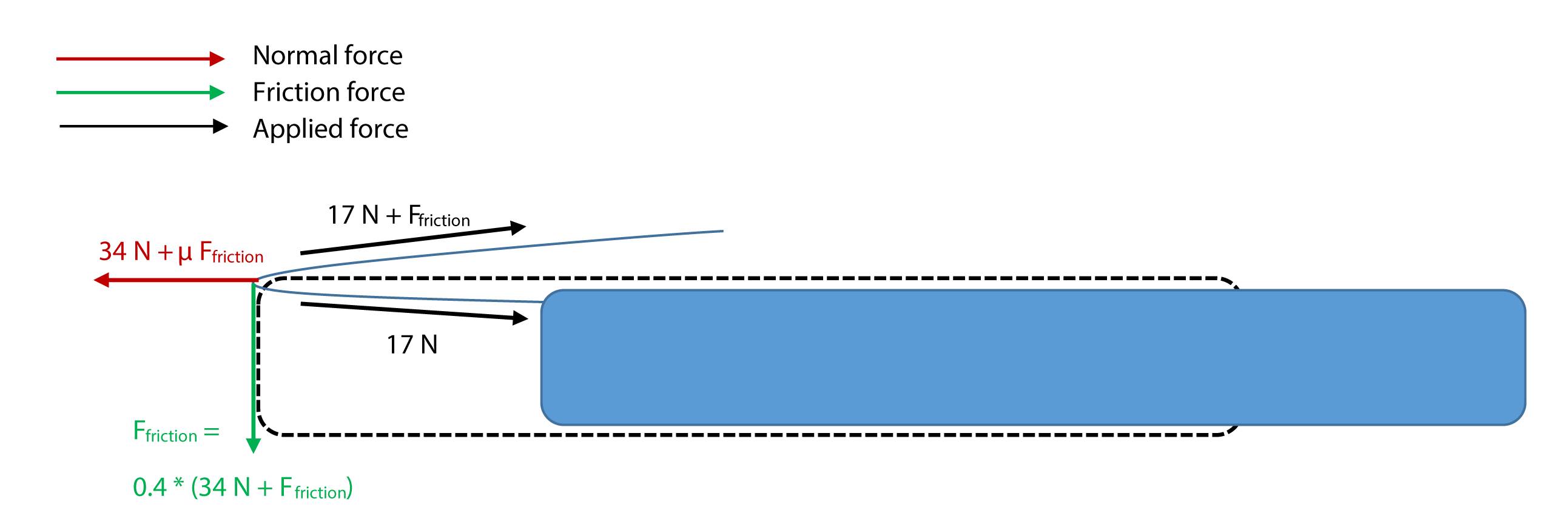

The friction force that acts on the rope at the edge of the pipe depends on the applied forces on the rope. This applied force depends on the Fpull from figure 1 and the friction force. So the friction forces depends partly on itself, shown in figure 2. Euler’s method can be used to solve this problem. The friction coefficient in 0.4. Start with computing the friction if there is no friction, after that use that friction to compute the next friction. Keep going until the limit is reached. This gives 0.4∙34=13.6 →0.4∙(34+13.6)=19.6 →0.4∙(34+19.6)=21.44 →0.4∙(34+21.44)=22.18, this keeps going until Ffriction=22.67. So the total force is Ftot=17+22.76≈40N. The engine has a torque of 4800 gram/cm, this is equal to 48 N/cm. So the maximum radius of the spool is r=1.2 cm. The figure below shows a schematic representation.

Demonstration

A video of the robot running a cleaning and harvesting routine can be found here (password: 0LAUK0).

A video showcasing the robot's actuation can be found here (password: 0LAUK0).

Code

The source code is available on the following page: PRE2015 4 Groep5 Code

Business and law

In 2014, the total annual value of produced seaweed was $6.4 billion. Worldwide, 93.8% of the global total production of aquatic plants came from aquaculture. Countries in East and Southeast Asia dominate seaweed culture production.[36] About 25 million tonnes of seaweeds and other algae are harvested annually for use as food, in cosmetics and fertilizers, and are processed to extract thickening agents or used as an additive to animal feed.[37] For the demand of food-grade seaweed to grow, there needs to be a dietary trend towards protein-rich vegetables, which seems to be the case. Growing the demand for seaweed requires a shift in the consumer's perception of seaweed as a food. Seaweed can be processed to be used as a source of nutrients for certain processed foods. There is increasing demand for seaweed as an agricultural supply, to use as animal food. It is also possible to use seaweed as a source for certain chemicals, for example for use in cosmetics.

Business case

Increasing demand for seaweed over the last fifty years outstripped the ability to supply requirements from natural (wild) stocks.[36] This increasing demand presents a fine opportunity for any entrepreneurs to enter the seaweed business. Currently most of the production is centered in Asia, with Europe representing only 0.01 percent of the total market. With Europe being such a small player on a global scale, and with demand outstripping supply, high-tech scalable automated seaweed farms could disrupt the global market and make Europe more competitive. This has domestic benefits, due to not having to import seaweed anymore. China, a huge market for seaweed, has been importing seaweed because it can't supply enough seaweed itself.

The province of Zeeland recently invested 300.000 euros in a research project of a chemical firm called Arkema Vlissingen, Wageningen UR and Northseaweed. They are researching the opportunities of seaweed farming in Zeeland. The province considers seaweed production as and opportunity to boost the local economy. [38]

Business model

The seaweed farm will not be cheap, due to its advanced technologies and special location. In order to make the investment worth it for the farmer, the farm will have to produce a lot of seaweed, and therefore cover a large area.

The seaweed market in the Netherlands is still relatively niche. The current producers are small. Therefore we do not expect them, or other future producers, to do a large investment in our farm, we need to find a way to offer our product on a small scale, that is still profitable. A lot of costs and resources would be saved if the seaweedfarm would be installed collectively, instead of scattered along the coastal areas. The energy generated by the energy buoy could be shared, the robot could be shared and the incoming environmental data too. In general, less material and surface area would be required, which would be beneficial for the environment and cause less nuisance to ships. If the farmer would have to learn as little as possible about the new system to use it, and just be concerned with the classic seaweedfarm that he is already using, we expect him to be more tempted to try the HASP.

When we take all this into consideration, we have to take a look at the new business models that the upcoming circular economy – aimed at building an economy that does not produce waste - offers us. In our business model, our product is not just a product, and our customers are not just customers. The seaweed farm will be offered as a service, of which the farmers will be the users. We will lease acces to our system, and adjust it to make it as reusable, and regenerative as possible. The tasks left for the user would be: picking, growing and planting the seedlings, checking on the crops when the system sends out an alarm, and picking up the harvest. The user could start out with one module and expand in the years to come, or adjust their production to their personal situations. Meanwhile, the tasks of us, the producers, would be the installation and the maintenance of the system.

We believe that by creating the opportunity to use HASP with low investments, flexibility, options for expansion and not requiring any new knowledge, we lower the threshold, and make our system as attractive and approachable as possible to the small seaweed producers that are active today in the Netherlands. The additional costs of using the system as a service, would be balanced out by the investment that would not have to be made, and the costs of maintenance and the education needed for that.

Cost vs. profit

Currently the most Seaweed farms are located in China, which makes the Chinese market very different from the European one. Therefore we will base our cost/profit analysis on a recent Irish study. These are the listed relevant costs and profits:

Costs:

- A seedling curtain, with 40.000 - 50.000 seedlings costs about 0.5-0.6 US Dollars.[6]

- A continuous rope seaweed system, similar but more superficial than our system. For a 100 ton production, a surface area op 900 square meters, and 450 meter line, including buoys and anchors, the system costs 84,128 EUR. [39]

Profit:

- Irish sources estimate the value of 1 KG laminaria on 1-2 euros. This would be the price for high-quality and seaweed that would be fit for human consumption. [39] The price difference with the Chinese market is notable. 1 KG of Chinese dry Laminaria Japonica is sold at the Chinese market price of 0.5 Chinese Yen, or 0.07 Euros. This would be the price for lower quality seaweed on a much bigger market. [40]

- It is estimated that a cultivation rope of 1 meter can produce about 7 kg of dried seaweed. This means that the vertical lines would account for 35 kg of harvest each year, which could be sold for 35-70 euros.

The efficiency of the automated farm enables the user to produce a lot more seaweed than without automation. More production means more revenue, but does it also mean more profit? We do not know by how much the production will increase with our system, and therefore we can not know wether the revenue would be higher than the investment.

Laws

An exclusive economic zone is a sea zone prescribed by the United Nations Convention on the Law of the Sea over which a state has special rights regarding the use of natural resources.[41] So states could allow their citizens to maintain sea farms in these areas, and could set their own rules for the use of these waters.

For international waters the United Nations Convention on the Law of the Sea also states that states have right for their nationals to engage in fishing. There are also obligations to adhere to the obligations of any treaties, take measures necessary for the conservation of living resources, this obligation to protect marine life also explicitly extends to the conservation and management of marine mammals in the high seas. The sea farms don't necessarily use up living resources, but could impact them. The sea farms also take up nutrients form the surrounding waters and release oxygen into the water. If a sea farm would be improperly implemented, for instance its sounds would harm marine mammals, then it would be a reason to block the use of the farms. However, for the proper use of these farms in international waters there would be a need to regulate the locations of the farms as to not block other seafarers.

For the use of the sea farms in international waters the main points are: adhere to international treaties, don't harm marine life and don't obstruct marine traffic.

Looking ahead

Room for improvement

The robot in our design will operate from 2 to 7 meters below the surface. Our current prototype would not be fit to stand the pressures found at such depths (0.7845 bar for eight meters, to be sure.) In a commercial design, the robot have to be more robustly constructed more.

In the current design, the modules all have their own buoys and anchors. It would be far more efficient if the buoys and anchors could be placed strategically, so that the modules can share them whilst keeping the advantages of modularity.

Many more activities of the user could be automated, like seeding and disease prevention. Especially seeding would be the first task to automate, if we had more time to work on the project. Seeding is a labour intesive task and can be problematic when the farmer has to directly access the growing lines, on a boat in the area where the navigation lines for the robot are drifting.

In order to be a substantial solution to the growing shortage of food. The HASP would have to be widely used. It's construction should be cheap enough to be able to sell its crops for an affordable price to the hungry. The system on itself is fit to function in different seas and climates, albeit with a different species of seaweed. The problem that needs to be solved to enable popular use (and therefore decrease food shortafe) is the business model. We have already tried to make the farm as economically attractive as possible to the users. The best way to lower the investment in the future would be to lower the production costs of the system itself. This will not be easy when the seaweed farm is still unknown. It will have to be given time to grow in popularity, to give it a chance to become cheap enough to feed the world. Another option would be to look away from the free market and convince NGO's or governments of the massive ethical benefits that this farm could provide, and ensure mass-adaption through subsidies or donations.

Seaweed can be used for the production of biofuels, which would beneficial to the climate. However, in this project we have not taken a closer look into the business opportunities of producing for bio fuels.

Future farms

The farm we have outlined only concerns the cultivation of seaweed. However, farms can be augmented by employing bivalves in order to filter the water of pollutants.[42]

Future farms should strive for maximum autonomy. Tasks that are carried out by people in the current prototype should be automated, for instance the planting of seedlings is to be replaced by on-site incubation of seedlings, and using a robot for putting them on a line.

The system we have described int his wiki is monocultural. However, studies show that a polyculture, with scallops and mussels for example is more profitable. [43] Polycultural farming is also beneficial to the production becasue the different species create a positive interaction. The seaweed species we plan to cultivate, Laminaria, combines very well with mussels. This is because Laminaria create a mini ecosystem with shade, protection from current flows, oxygen and generally more fertility. Mussels can thrive in such an enviroment. In exchange, the mussels provide nutrients when they "mussel poop". This combination hightens the quality of the production and therefore increases value. In fact, the market values of laminaria cultivated in a polyculture, were 27% and 31% higher respectively. [44]A positive byproduct is the good impact on the enviroment. We did not design a polycultural system because it would complicate the tasks to be carried out by the robot. Mussel ropes would have to be suspended between the kelp ropes, and how would the robot handle those? This is a problem that should be solved in the future, to make future farms more society- and enterprise- friendly.

Recommendations

Horizon 2020

Applicable areas:

- Agriculture & forestry

- Aquatic resources

- Bio-based industries

- Environment & climate action

- Food & healthy diet

- Innovation

- SME (small-medium enterprise)

Relevant research calls:

- High value-added specialized vessel concepts enabling more efficient servicing of emerging coastal and offshore activities.[45] € 7 million

- New sources of proteins for animal feed from co-products to address the EU protein gap.[46] € 15 million

- Promoting and supporting the eco-intensification of aquaculture production systems: inland (including fresh water), coastal zone, and offshore.[47] € 6 million

Also Marine Knowledge 2020 with The European Marine Observation and Data Network (EMODnet), aims to collect a lot more data from the seas and oceans than we do at the moment.[48]

Discussion

The intial problem that we tried to solve, the growing demand for food worldwide, was a societal problem. But aside from the societal aspect, we have tried to base our design decisions on the needs of all the stakeholders: users, society and enterprise.

The decision to farm Laminaria on our system benefits the users, with an easily cultivatable species. Society benefits because the enviroment remains unharmed with the non-invasive aspect of Laminaria. Aside from that, the seaweed can be used to produce food for cattle and replace soy. This could benefit the climate because there would be no more need for deforestation for creating fields for soy production. Another climate/society benefit would be the use of seaweed for biofuels, which would be far less polluting than the current use of fossil fuels. Finally Enterprise benefits from the demanding market for Laminaria and its high value which makes the species profitable.

Our chosen location Zeeland benefits the user of the HASP by making the farm relatively easy to access. Society benefits in two ways. Firstly, the HASP contributes to the revival of the former deadzone in the North Sea. Secondly, the wave breaking qualities of the farm help in the protection of the vulnerable coast. Enterprise benefits from this location because the local Zeeland economy gets a boost. Besides, enterprise is not disadvataged because the HASP will not be located in one of the important commercial shipping routes.

For the system's power source, we decided to use a power buoy. This would be very user friendly, because its energy production is rather continuous, the system is highly autonomous with its own energy source, and the buoy can remain in one place. Society profits because the buoy provides sutainable energy and has zero CO2 emissions. Therefore the climate is done no harm and it does not contribute to climate change.

The modular construction of our system enables a farmer to use the system as a service, rather than a product. User and Enterprise share the benefits in this case. Because the farmer can start with only one module and then expand, the treshold for the investment remains low. Society benefits because the modularity increases the ease of repairablitity and therefore sustainability. Besides, the farms of multiple farmers could be located together, which would enable them to share resources. Compared to multiple farms scattered along the coast, this would be better for the enviroment and be of less nuisance to commercial ships.

These decisions created positive benefits to all of the stakeholders. However, as described in a previous section, there is still room for improvement. More research and time could enlarge the number of benefits and expose some negative aspects that would need to be solved.

Conclusion

Looking back at our problem statement, we decided to design an automated seaweedfarm to solve the growing problem of food shortage. However, as our research continued, we discovered that our solution would also do well in the industrial and non-food market of iodine production. Cultivating seaweed for animal feed production also apeared to be an option, and the farm itself would be beneficial to the enviroment. After working through this maze of positives, it is now time to ask ourselves: did we design a solution to the world's growing hunger?

The research that we have done resulted in a final design and prototype of our automated seaweedfarm. These two deliverable have brought the HASP several steps closer to realizsation. Broad usage of our system could be the solution to the problem that we initially stated: the worldwide insufficient food production. Therefore we can conclude that we have partially succeeded in solving our problem statement and several other additional problems.

Sources and references

Sources

- CCCen (2015), Maritime Robotics 32C3

- Climate council (2016) How seaweed can help us tackle climate change

- Doty, M.S. & Caddy, J.F. & Santelices, B. (1987), Case Studies of Seven Commercial Seaweed Resources

- Flannery, Tim (2015), Climate crisis: seaweed, coffee and cement could save the planet

- Foscarini, Roberto & Prakash, Jayant (1990), Handbook Seaweed Cultivation

- Gruendl, Harald & Haele, Ulrike & Kellhammer, Marco & Nägele, Christina (2014), Tools for the Design Revolution - IDRV Institute of Design Research Vienna

- Juanich, Godardo L. (1988), MANUAL OF RUNNING WATER FISH CULTURE(1. EUCHEUMA SPP.)

- Kitadai, Yuuki & Kadowaki, Shusaki (2007), Growth, nitrogen and phosphorous uptake rates and O2 production rate of seaweeds cultured on coastal fish farms

- Kleis, Roelof (2010), Growing seaweed can solve acidification

- Lacey, Stephen & Mellino, Cole (2011), Seaweed Aquaculture: An Answer to Sustainable Food and Fuel?

- Merchant, Brian (2015), The last time oceans got this acidic this fast, 96% of marine life went exinct

- NOAA Ocean Explorer Webmaster (2013), NOAA Observing Systems and Sensors

- Phillips, M.P. (1990), ENVIRONMENTAL ASPECTS OF SEAWEED CULTURE

- Popper, Arthur N. & Hastings, Mardi C. (2009), The effects of human-generated sound on fish

- Smith, Bren (2016), The Seas Will Save Us: How an Army of Ocean Farmers are Starting an Economic Revolution

- World map of sea-depth (slow commection), faster image.

- euRathlon (2015), Home page euRathlon

- Mate, Marine Advanced Technology Education

- Sauvc (2016), The Singapore AUV challenge

- World robotic sailing championship

References

- ↑ Food security

- ↑ Food Security: The Challenge of Feeding 9 Billion People

- ↑ Agriculture & Forestry

- ↑ Agricultural Robotics and Automation

- ↑ Mariculture

- ↑ 6.0 6.1 FAO Laminaria

- ↑ Seaweed Site

- ↑ Gelidium Amansii

- ↑ Nineteenth International Seaweed Symposium

- ↑ FAO Porphyra

- ↑ [1]

- ↑ Growth, nitrogen and phosphorous uptake rates and O2 production rate of seaweeds cultured on coastal fish farms

- ↑ Noordzee Scheepvaartroutes

- ↑ Serge Mabeau, Joël Fleurence: Seaweed in food products: biochemical and nutritional aspects (1993)

- ↑ P. Rupérez: Mineral content of edible marine seaweeds (2002)

- ↑ Joël Fleurence, Michele Morançais, Justine Dumay, Priscilla Decottignies, Vincent Turpin, Mathilde Munier, Nuria Garcia-Bueno and Pascal Jaouen: What are the prospects for using seaweed in human nutrition and for marine animals raised through aquaculture? (2012)

- ↑ Joël Fleurence: Seaweed proteins: biochemical, nutritional aspects and potential use (1999)

- ↑ 18.0 18.1 Holdt, Susan Løvstad, and Stefan Kraan. "Bioactive compounds in seaweed: functional food applications and legislation." Journal of Applied Phycology 23.3 (2011): 543-597.

- ↑ Arasaki, Seibun, and Teruko Arasaki. "Vegetables from the sea." Japan Publ. Inc., Tokyo 96 (1983): 251-223.

- ↑ Kumar, K. Suresh, K. Ganesan, and PV Subba Rao. "Antioxidant potential of solvent extracts of Kappaphycus alvarezii (Doty) Doty–An edible seaweed." Food chemistry 107.1 (2008): 289-295.

- ↑ 21.0 21.1 Sustainability of meat-based and plant-based diets and the environment

- ↑ Carcinogenicity of consumption of red and processed meat

- ↑ Does Military Sonar Kill Marine Wildlife

- ↑ Davide Anguita, Davide Brizzolara, Giancarlo Parodi. Building an Underwater Wireless Sensor Network based on Optical Communication: Research Challenges and Current Results.

- ↑ Ian F. Akyildiz, Dario Pompili, Tommaso Melodia. Underwater acoustic sensor networks: research challenges

- ↑ How do you determine if a sound affects a marine animal

- ↑ Ocean Energy Europe

- ↑ Watertemperatuur Noordzee

- ↑ [2]

- ↑ J.J. Bolton and K. Lüning. Optimal Growth and Maximal Survival Temperatures of Atlantic Laminaria Species in Culture. 1982

- ↑ [ http://www.fao.org/fishery/culturedspecies/Laminaria_japonica/en]

- ↑ Number of plants on a Chinese farm line

- ↑ [ http://www.fao.org/fishery/culturedspecies/Laminaria_japonica/en]

- ↑ [3]

- ↑ [4]

- ↑ 36.0 36.1 A guide to the seaweed industry

- ↑ The State of World Fisheries and Aquaculture 2014

- ↑ [5]

- ↑ 39.0 39.1 [6]

- ↑ FAO Artificial Enhancement of Natural Laminaria Stocks

- ↑ Exclusive Economic Zone

- ↑ Biosorption and bioaccumulation of heavy metals by rock oyster Saccostrea cucullata in the Persian Gulf

- ↑ [7]

- ↑ [8]

- ↑ Horizon 2020 (1)

- ↑ Horizon 2020 (2)

- ↑ Horizon 2020 (3)

- ↑ EMODnet