Integration Project Systems and Control 2013 Group 2: Difference between revisions

Jump to navigation

Jump to search

| Line 31: | Line 31: | ||

{| | {| | ||

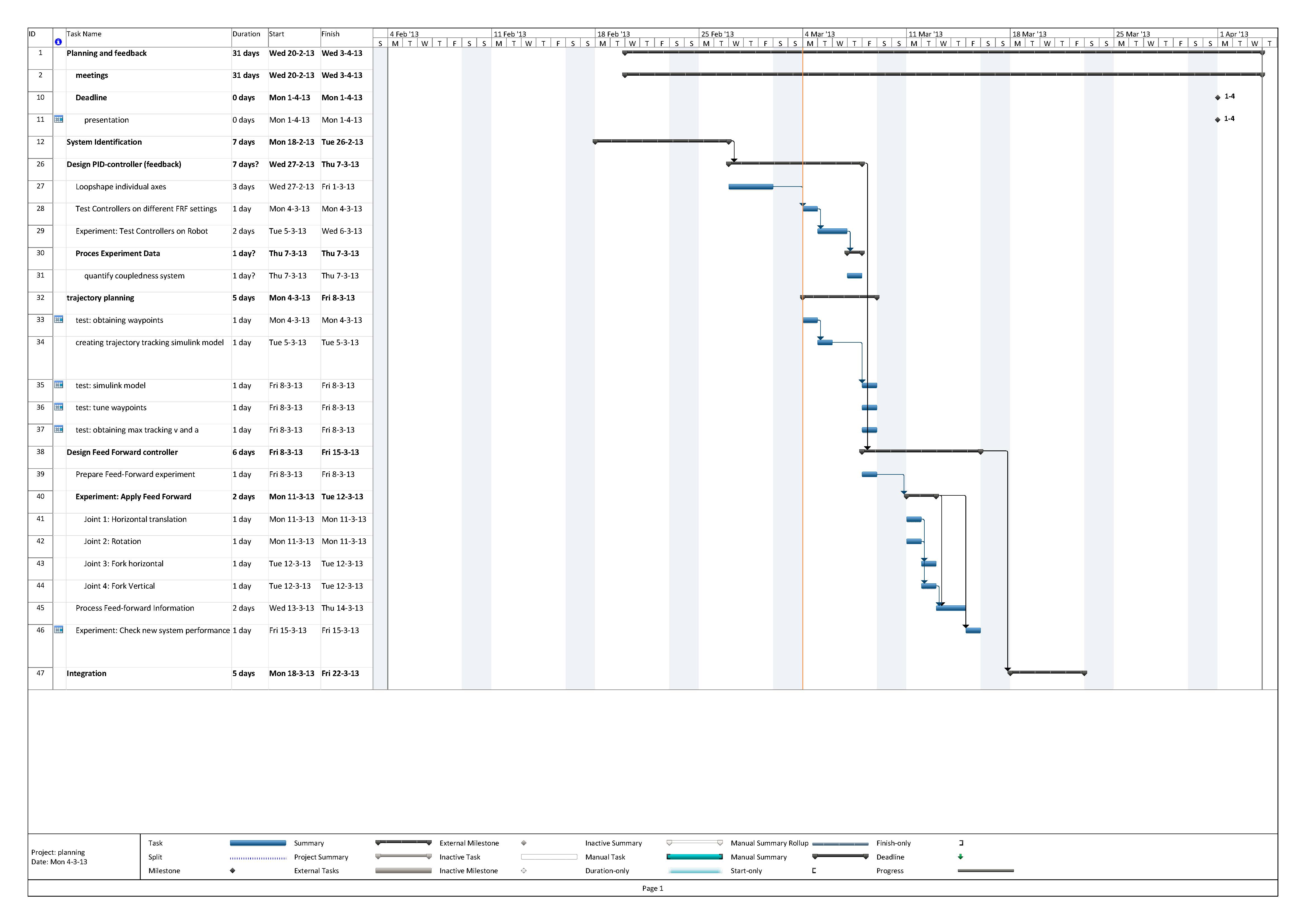

[[File: | [[File:planning1.jpg|thumb]] | ||

|} | |} | ||

Revision as of 10:04, 4 March 2013

Group Members

| Name: | Student id: | Email: |

| Rens Samplonius | 0785119 | r.j.samplonius@student.tue.nl |

| Frank Evers | 0789890 | f.evers@student.tue.nl |

| Juan Guo | 0825223 | j.guo@student.tue.nl |

| Jeroen Lamers | 0771264 | j.w.lamers@student.tue.nl |

Planning

Progress

Week 1

- List of what you have done and learned

- ...

Week 2

- Rens and Jeroen conducted an FRF measurement on the left pizza robot. They did a closed loop measurement on each axis by applying a sin-wave + white noise to the plant. The sine wave is added to overcome the massive friction. The controller used in the closed loop measurement is tuned very low. During the FRF measurement the following data is collected: the input signal (u), the white noise signal (w), and the output voltages (v). With this data we calculated the process sensitivity and the sensitivity and to obtain the plant we divided them (similar as we did during the Motion Control course). We are uncertain if the left and right pizza robots have a similar plant so perhaps we should repeat the FRF measurement on the right robot because that one has the pizza racks on it.